E4

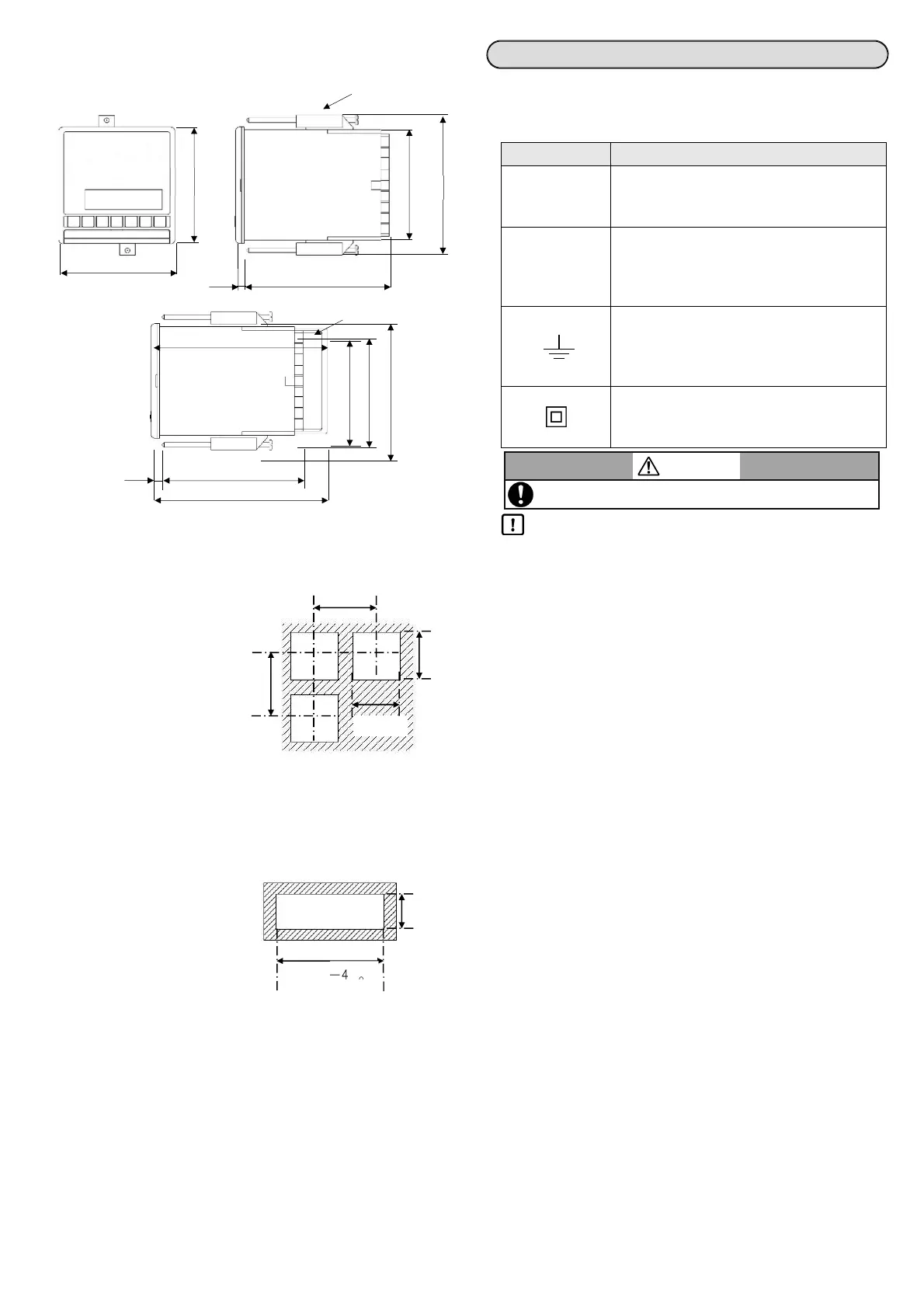

External Dimensions

KP1000 / KP2000 / KP3000 Unit : mm

Panel cutout and mounting dimensions

Usual mounting method

(1) Insert the controller in panel

cutout.

(2) Fit in the attached mounting

bracket above and below and

tighten the screws with the driver

and fix it.

The tightening torque of the

screws is '0.6 to 0.8 Nm'.

(3) For IP54 panel sealing

specifications, confirm that the

gasket between product and

panels is correct.

Take care because if the gasket

drifts or if there is a gap, the

mounting is not proper and the

water proofing function does not

work.

Closed instrumentation

(1) Insert the controller in panel

cutout.

(2) Fit in the attached mounting

bracket above and below and

tighten the screws with the driver

and fix it.

The tightening torque of the

screws is '0.6 to 0.8 Nm'.

(3) At the time of closed

instrumentation, in the product of

IP54 panel sealing specifications,

as the gasket functionality

between the product and the

panel is lost, water proofing

functionality does not work.

Step 2. Wiring

Symbol mark

The following symbol marks are used in this product itself and in this

instruction manual hence understand the meaning of these symbol

marks properly.

Label Meaning

If there is a possibility of death or severe

injuries then it explains the precautions to avoid

that possibility.

If there is a possibility of small injuries or a

possibility of the controller or its nearby devices

getting damaged then it explains the

precautions to avoid those possibilities.

It is a symbol for ground terminal.

Connect the ground terminal to the ground

terminal of the equipment. It is not a protective

conductor terminal.

Indicate the device which entire outline is

protected by double insulation or reinforced

insulation.

Precautions during wiring

• Wiring operation should be done by professional

Wiring should be done by a person having actual experience and

basic knowledge of instrumentation.

• Mount the terminal cover

In order to ensure safety, after the wiring is done, take measures so

as to prevent direct contact with the terminal of the product.

Exclusive terminal cover of the instrument is available as accessory

(Sold separately).

• Keep away from strong power circuit and noise sources

In order to prevent adverse effect due to noise, do not place the

instrument near a device from which noise is generated (magnet

relay, motor, thyristor regulator, inverter etc.). Also avoid passing the

wiring of the instrument and that of noise generating devices through

the same duct. Always keep the wiring away from each other. Take

the necessary countermeasures against noise.

• Effect on measured values

If there is a possibility that the measured values are affected by the

above noise, high voltage, etc., check that the measured values are

normal using other measurement methods. Take measures if

necessary.

• Keep away from the heat generating sources

In order to prevent adverse effect due to high temperature, do not

place the instrument near the heat generating sources. If the

instrument is kept near any heat generating source, measurement

goes wrong and finally the life of the instrument is shortened. Pay

attention to the surrounding temperature of the instrument.

Avoid places where there is wind and sudden temperature change, it

also causes an error in measurement. Take necessary measures to

avoid such surrounding environment.

• Unused terminals

Do not connect anything to the unused terminal. Instrument may get

out of order.

• Countermeasures against erroneous output at the power ON

When power is ON, sometimes the output related signal may be

momentarily output when the instrument is starting normally.

Take necessary countermeasures by using an external circuit.

• About the devices and equipment connected to this device

Make sure that devices and equipment connected to this device

have reinforced insulation suitable for the maximum operating

voltage of this device's power supply and input/output ports.

Basics of wiring

Refer to Instruction manual (General) 4-3-2 Basics of wiring for

connection to the terminal and about power supply terminal.

WARNING

Electric shock may occur, make sure to turn OFF the power

and

erform the

anel mountin

and/or wirin

o

eration.

96

96

Mounting bracket

×

120 7

Terminal cover

88×88

91×91

115

120

7

147

0

92

92

120

120

+0.8

0

+0.8

96×N-4

0

+2

N: Number of mounted instruments

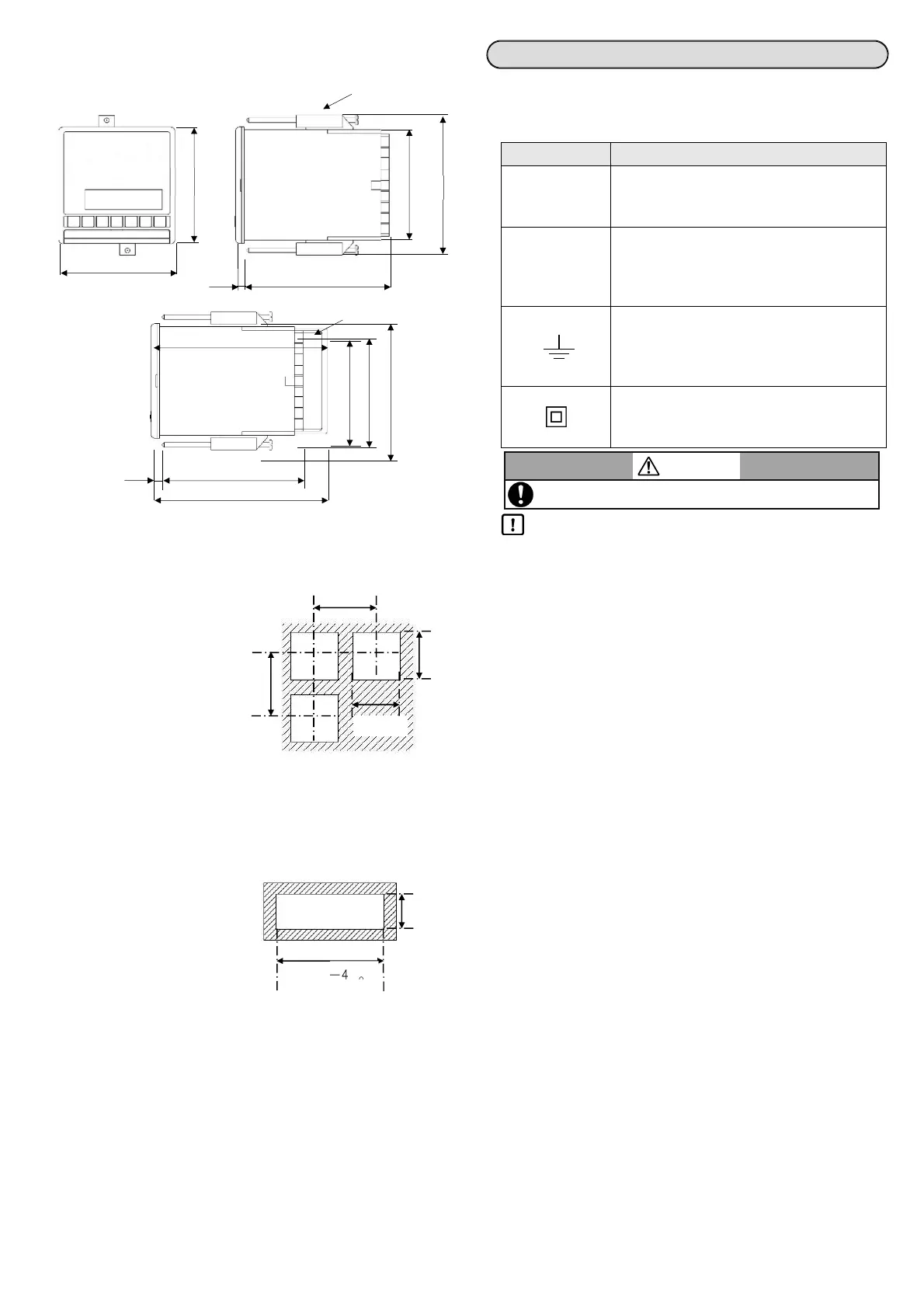

Panel cutout for closed installation

92

+0.8

Warning

Precaution

Unit : mm

Unit : mm

Loading...

Loading...