20

Selection of piping dimensions

Select refrigerant branching dimensions between outdoor units and connection kit, between connection kit and

indoor units according to the Operation & Installation Manual of outdoor units and indoor units.

Dimensions (mm) of connection pipe of the vale box

model

Dimension

(

outer diameter

)

Gas pipe/ convertible dimension Liquid pipe/ convertible dimension

AH1-280A Ø25.4/Ø22.22/Ø19.05 Ø9.52/Ø12.7

AH1-560A Ø28.58/Ø25.4/Ø22.22 Ø9.52/Ø12.7

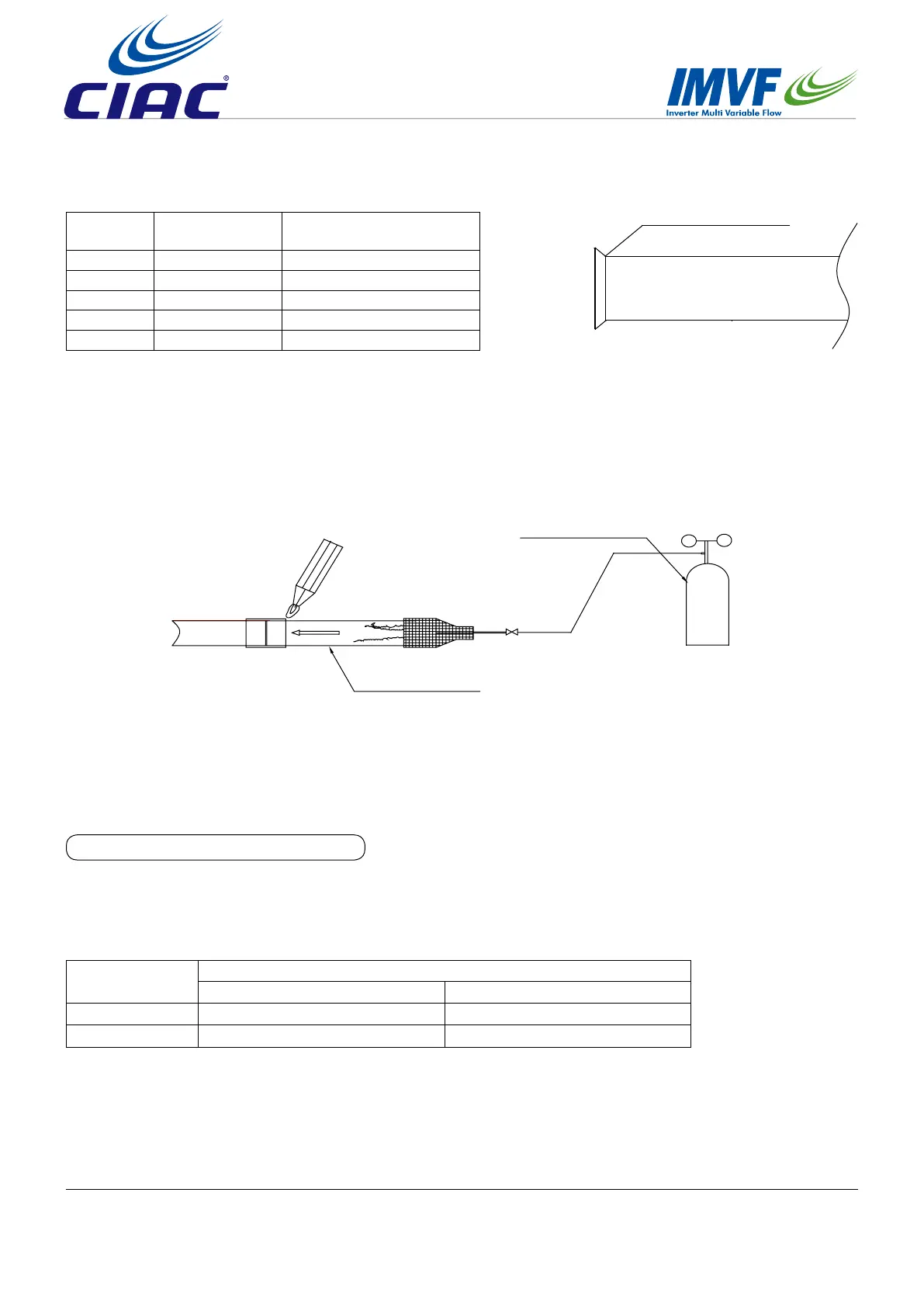

Nitrogen cylinder

Refrigerant pipe

Nitrogen

Nitrogen

Weld

Binding

<Note>

• For pipe welding, do not use antioxidant, for its residue may cause tube blocking and component fault.

• For pipe welding, do not use ux. If the ux is chlorine product, it will corrode the tube; if it contains uorine, it will

even cause detrimental effects to the refrigerant system, such as refrigerant oil deterioration. Please do not use

phosphor copper for welding material (BCup-2).

<Note>

• Excessive tightening will result in cracking at the are and refrigerant leakage.

• To weld the refrigerant pipe, please make nitrogen replacement (*1), or send nitrogen (*2) into the refrigerant pipe

while welding the pipe (refer to Fig.3). Finally use the are or ange to connect the indoor unit and connection

kit.

(*1) Nitrogen replacement method is provided in the multi-split system work manual.

(*2) If nitrogen owing and welding proceed simultaneously, do use pressure reducing valve. Approximately 0.02

MPa (0.2 Kg/cm with a slight feeling of breeze) pressure is quite proper.

<Table-2>

Pipe size Tightening angle

Recommended tool length

(mm)

Ø6.35 60°~90° 150

Ø9.52 60°~90° 200

Ø12.7 30°~60° 250

Ø15.88 30°~60° 300

Ø19.05 20°~35° 450

Apply refrigerant oil

Loading...

Loading...