9-4

EM-573 (N-04-18)

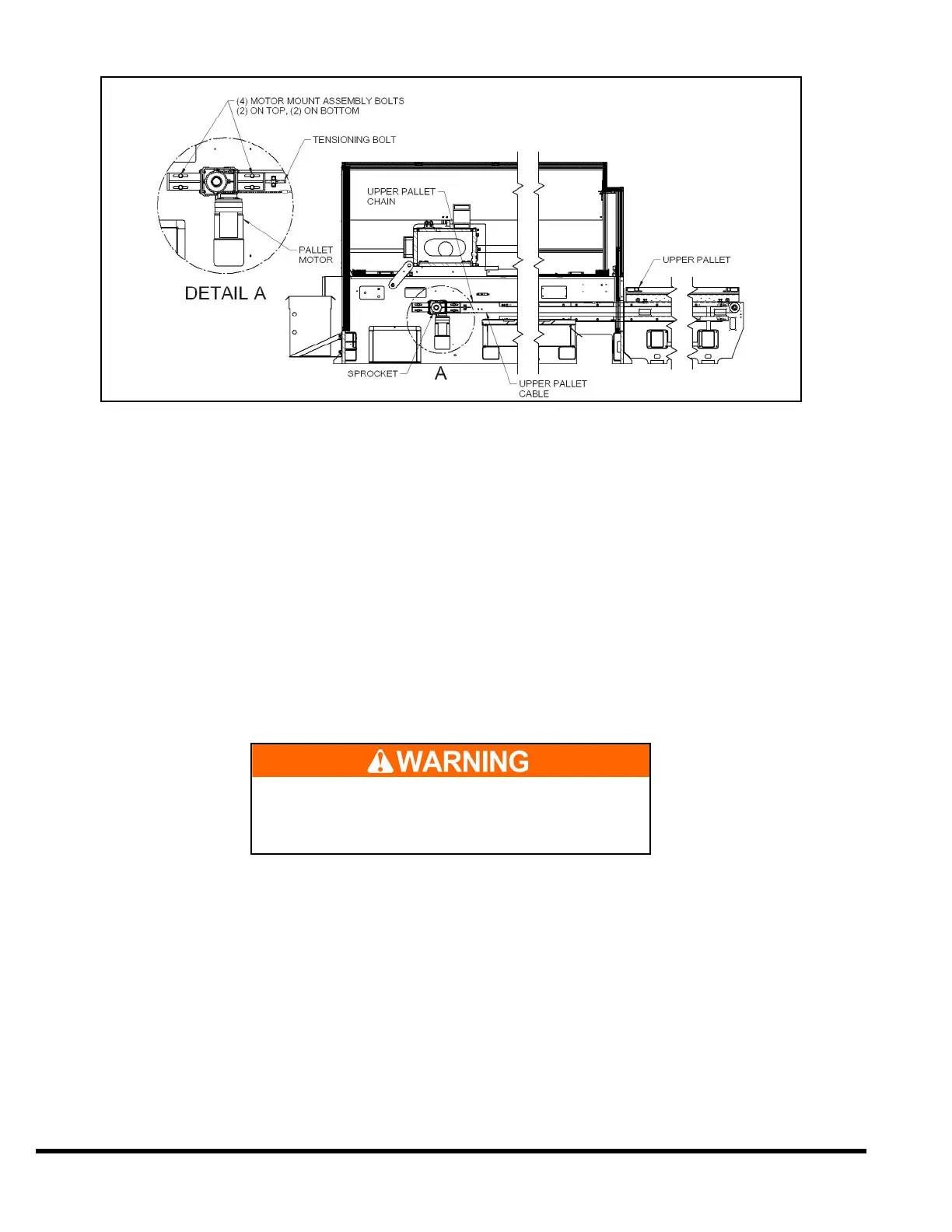

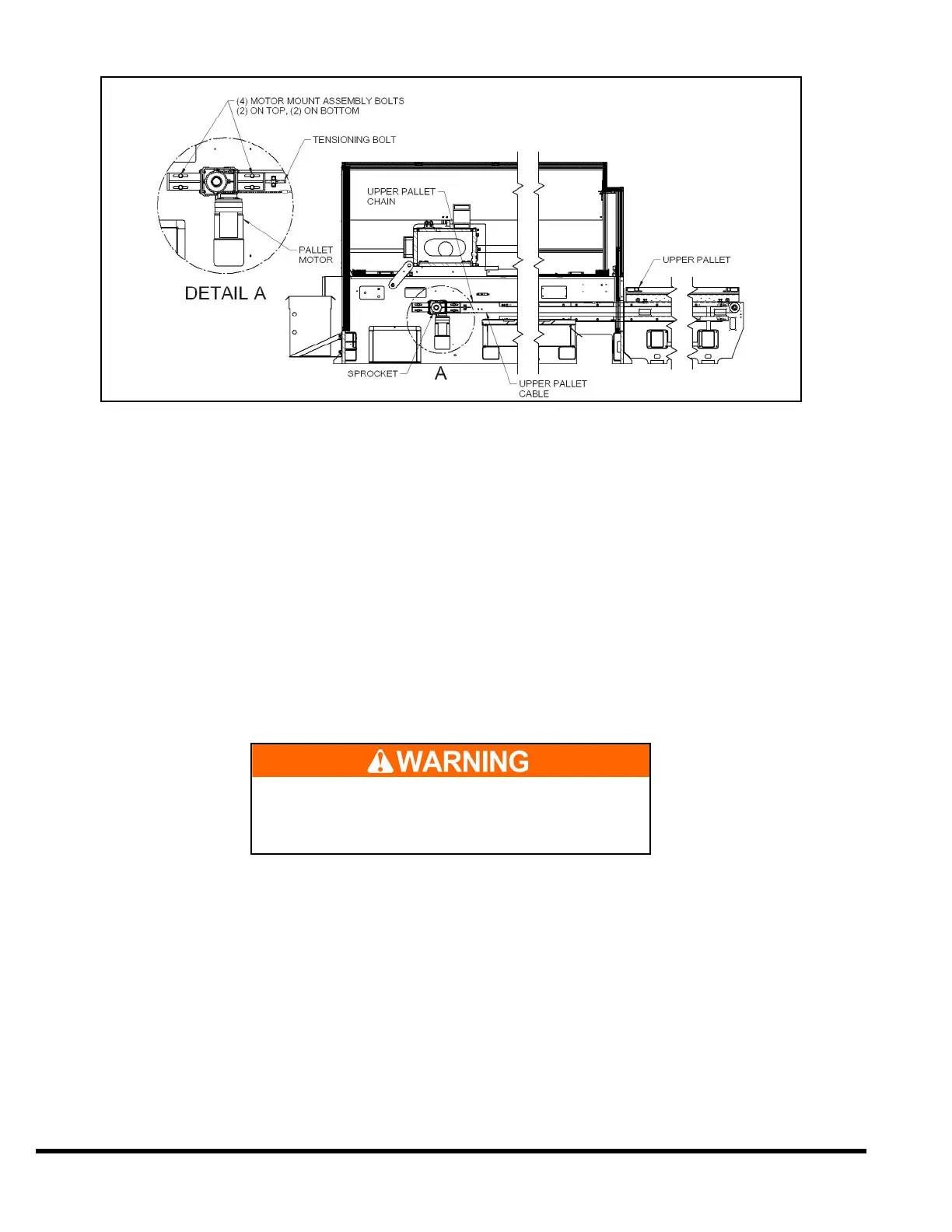

Figure 9-5 Adjusting pallet Cable Tension

SCRAP REMOVAL

The scrap removal system is designed to remove scrap material from the cutting area after processing. The

system components are: scraper plates attached to the lower pallet, scrap tray mounted on top of the fume

collection plenum, and a scrap cart with removable scrap totes.

When cutting has completed on the lower pallet and the pallets change positions, the lower pallet will move from

the main frame to the load frame. As the pallet moves, the scraper plates push scrap accumulated on the scrap

tray into scrap totes located near the load frame end of the main frame.

When the pallet lls the scrap cart, pull the scrap cart out of the main frame and empty the totes.

Clean the scraper plates to remove laser slag as needed. To remove a plate, pull the pin from the hinge and

lift the plate out. Clean the scrap trays if slag build-up prevents the scraper plates from functioning properly or

inhibits proper fume collection. Also clean the pull-out totes.

Fire hazard is present in the processing area

through interaction of the laser beam with

materials present in the work area.

Debris and ne particulate generated from laser cutting some materials, (i.e. plastics, aluminum, fabrics, etc.),

can present a re hazard if allowed to accumulate. Good housekeeping practice should be followed so the area

below the cutting zone is inspected daily and cleaned on an as-needed basis or every 1000 hours of operation.

The fume collection plenum (air collection duct) below the cutting zone should also be checked for debris

accumulation. Removable covers are provided for this inspection and cleaning. See Section 3 - SAFETY,

FIRE, for more information.

PALLET GUIDE RAILS

Maintenance required for the pallet guides consists of periodic cleaning of the guide rails in the Main Frame

and Load Frame.

Remove dirt and debris from the entire length of the upper and lower rails on a regular basis. As a guideline,

inspect the rails weekly and, if necessary, clean with a stiff brush and a non-ammable, nontoxic solvent.

Loading...

Loading...