CIRRUS AIRPLANE MAINTENANCE MANUAL MODELS SR22 AND SR22T

24-30

Page 27

All

EFFECTIVITY:

(5) Inspection/Check - Master Control Unit

(a) Acquire necessary tools, equipment, and supplies.

(b) Set BAT 1, BAT 2, and AVIONICS switches to OFF positions.

(c) Remove engine cowling. (Refer to 71-10)

(d) Disconnect battery 1. (Refer to 24-30)

(e) Remove MCU cover. (Refer to 24-30)

(f) Visually inspect inside MCU for evidence of water. If water if found, dry MCU and compo-

nents with a clean cotton cloth.

Note: Evidence of surface corrosion does not require replacement of MCU com-

ponents. If corrosion is found, verify MCU operation by performing Opera-

tional Inspection - Master Control Unit.

(g) Apply corrosion inhibitor as follows:

1

Cover surrounding components and structures to prevent inadvertent application of

corrosion inhibitor to these areas.

2

Apply a thin coat of corrosion inhibitor to MCU circuit board, internal components,

and connectors per the manufacturer’s instructions.

(h) Verify security of MCU chassis to firewall.

(i) Visually inspect cable assemblies and connector wires for chafing and security.

(j) Serials w/ MCU 100 or MCU120: Visually inspect sealant for a tight seal around cable

guide holes where cable assemblies and connector wires exit MCU.

(k) Serials w/ MCU 100 or MCU120: If necessary, reapply sealant to MCU as follows:

1

Solvent clean areas of MCU to be sealed. (Refer to 20-30)

2

Apply sealant around cable guide holes where cable assemblies and connector

wires exit MCU.

(l) Install MCU cover. (Refer to 24-30)

(m) Connect battery 1. (Refer to 24-30)

(n) Install engine cowling. (Refer to 71-10)

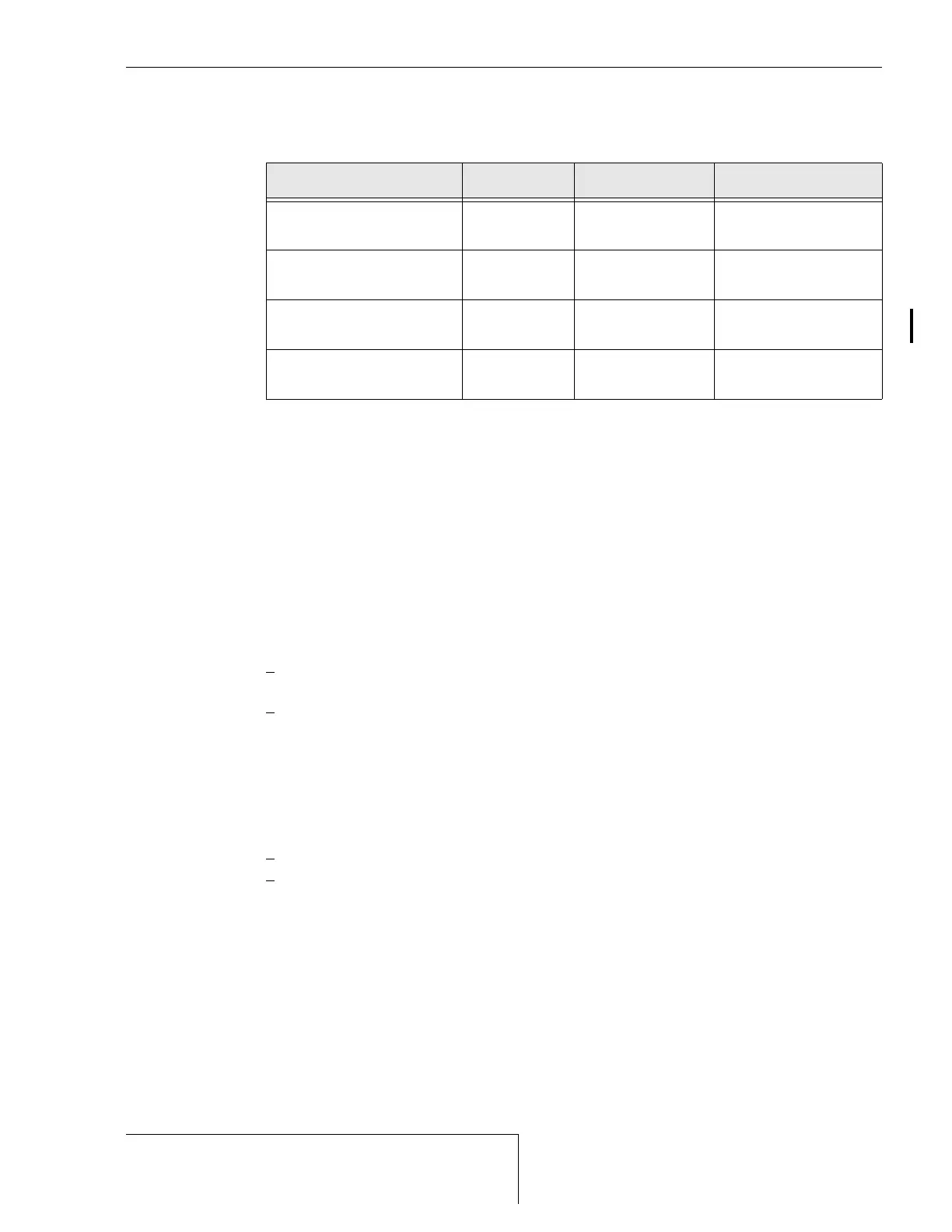

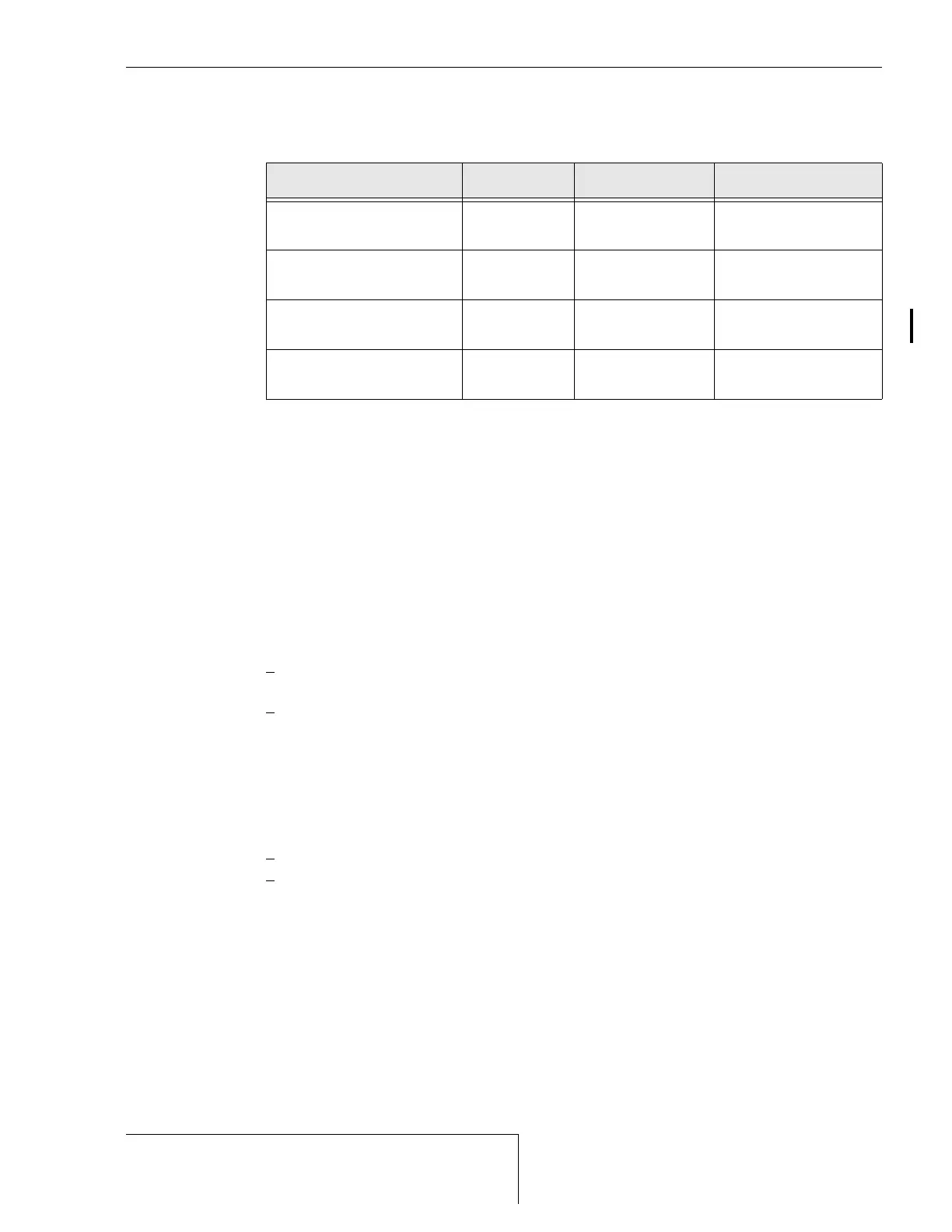

Description P/N or Spec. Supplier Purpose

High Temperature Sili-

cone Sealant

RTV 736 Dow Corning Sealant.

Cotton Cloth

(clean and lint free)

- Any Source General Cleaning.

Isopropyl Alcohol 99% or

higher purity

Any Source Solvent clean.

Corrosion Inhibitor

(aerosol)

MIL-C-81309

Type III

Any Source Prevent corrosion.

15 Dec 2014

Loading...

Loading...