Applications

The sensor of FLUEREX consists of a rectier that converts the

compressed air to a uniform ow and a platinum thin lm resistor that

detects the ow rate. The rectier works to make the ow uniform

when a bent pipe such as an elbow is installed immediately before the

sensor. Through the use of multiple rectication plates, the pressure

loss is suppressed and an adequate rectication effect is realized.

When the compressed air does not ow, the platinum thin lm

sensor that detects the ow rate is heated from the uid temperature

to a certain constant temperature. When the compressed air ows,

the amount of heat proportional to the weight of air is detracted and

the current that intends to maintain the constant temperature ows

in the circuit inside the platinum thin lm sensor that detects the ow

rate. By receiving this current as a ow rate signal, the display

section displays a practical atmospheric pressure, instantaneous

ow rate or integrating ow of the air converted to 0°C.

In addition, by the platinum thin film sensor that detects the

fluid temperature, the temperature of the compressed air is

measured and the temperature correction is performed.

Functions

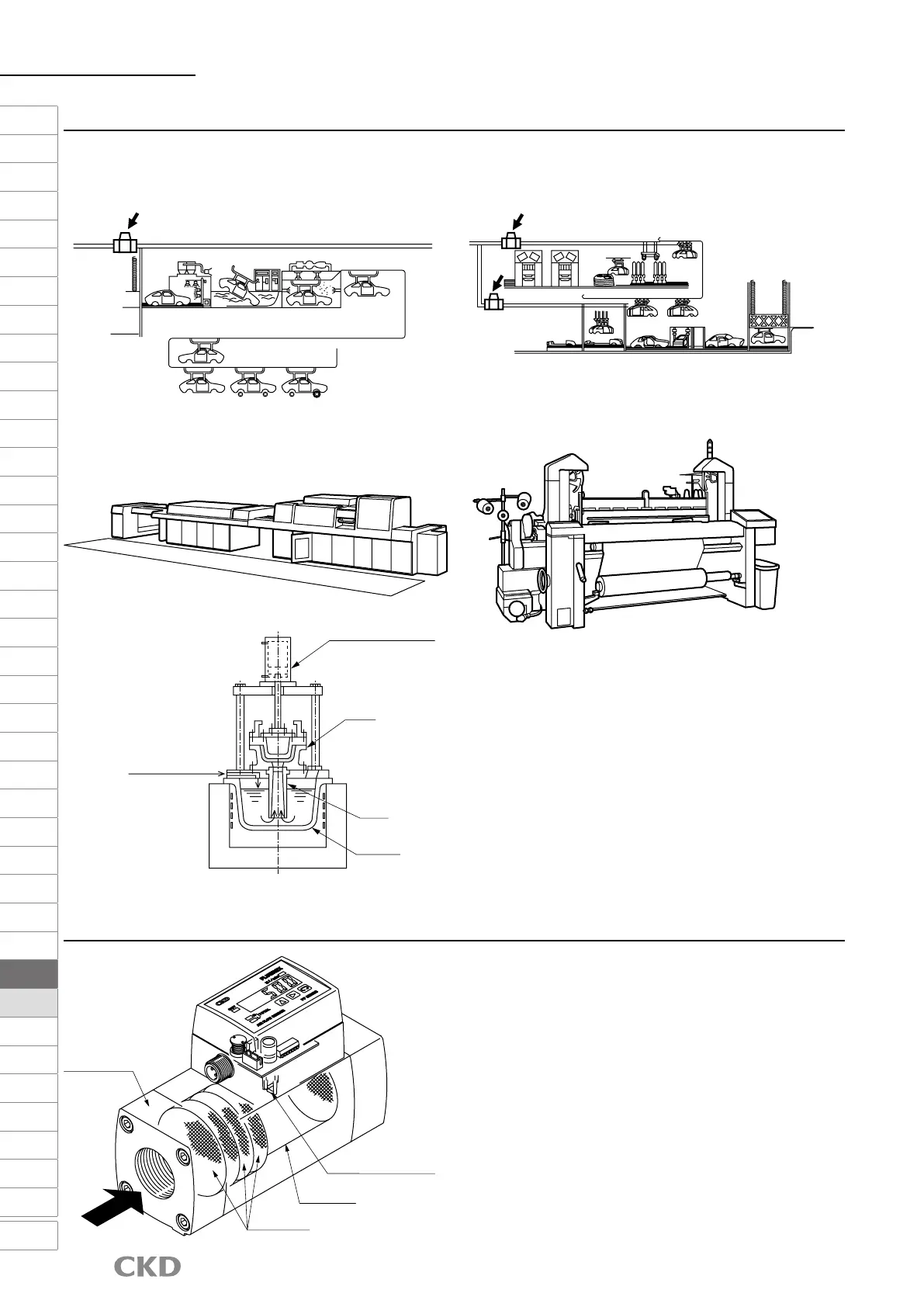

For ow rate management of paint line

For ow rate management of line of an auto plant

●

For ow rate management of each line!

●

Cost conversion is possible using integrating ow display

For semiconductor manufacturing equipment

●

For ow rate management of expensive low dew-point air!

Also for early detection of trouble such as "excessive ow

rate"!

For ow rate management of weaving machine plant

For low pressure casting

machine

●

For mold cooling temperature

management!

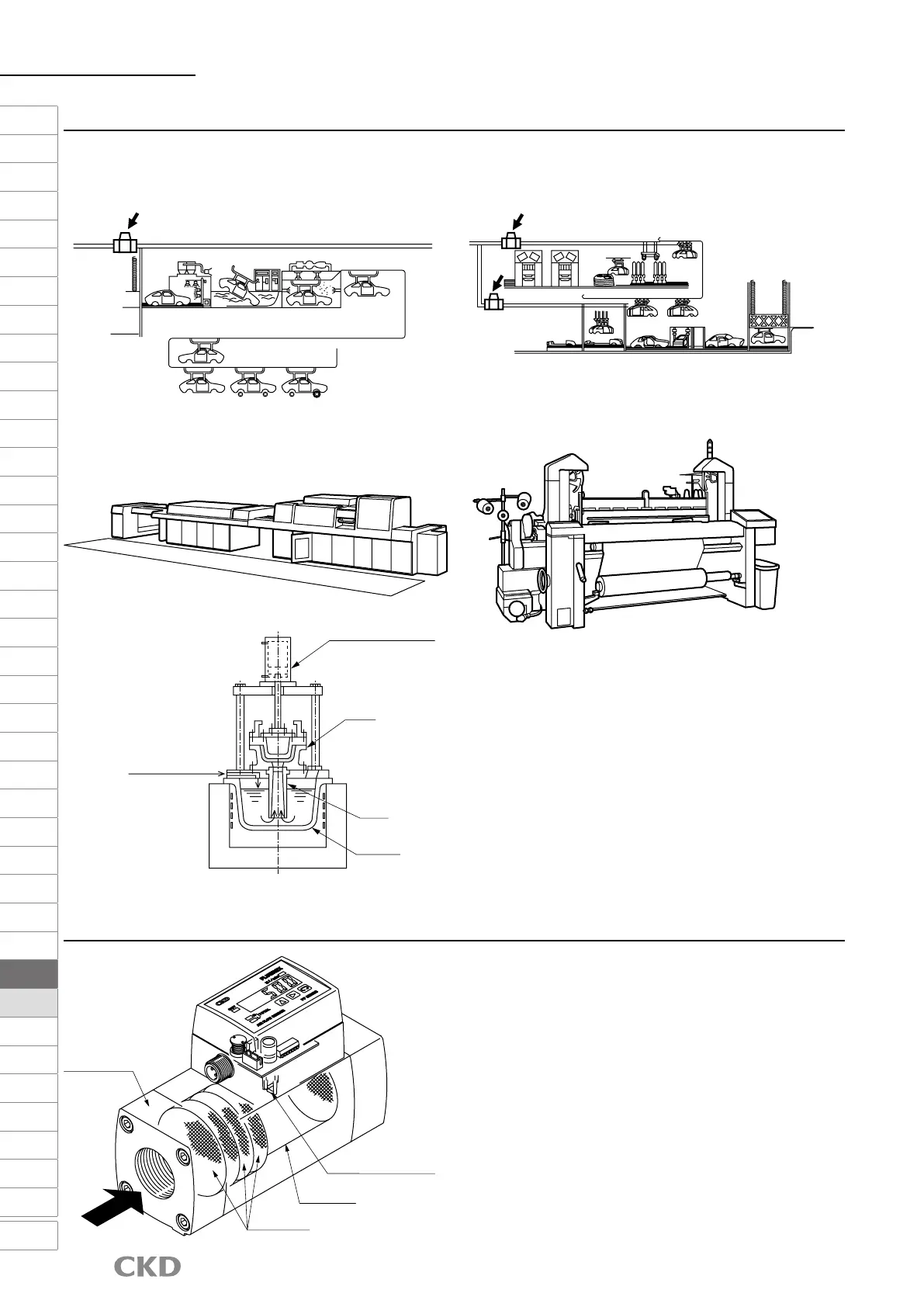

PF-F Series

Molten metal

Compressed air

Punch-out cylinder

Mold

Stoke

Crucible

Flow path

Fluid direction

Rectier

Platinum thin lm sensor

Pipe adaptor

F.R.L

F (Filtr)

R (Reg)

L (Lub)

PresSW

Shutoff

SlowStart

FlmResistFR

Oil-ProhR

MedPresFR

No Cu/

PTFE FRL

Outdrs FR

F.R.L

(Related)

CompFRL

LgFRL

PrecsR

VacF/R

Clean FR

ElecPneuR

AirBoost

SpdContr

Silncr

CheckV/

other

Jnt/tube

AirUnt

PrecsCompn

Mech/

ElecPresSw

ContactSW

AirSens

PresSW

Cool

AirFloSens/

Contr

WaterRtSens

TotAirSys

(Total Air)

TotAirSys

(Gamma)

RefrDry

DesicDry

HiPolymDry

MainFiltr

Dischrg

etc

Ending

1370

Loading...

Loading...