PPX

Series

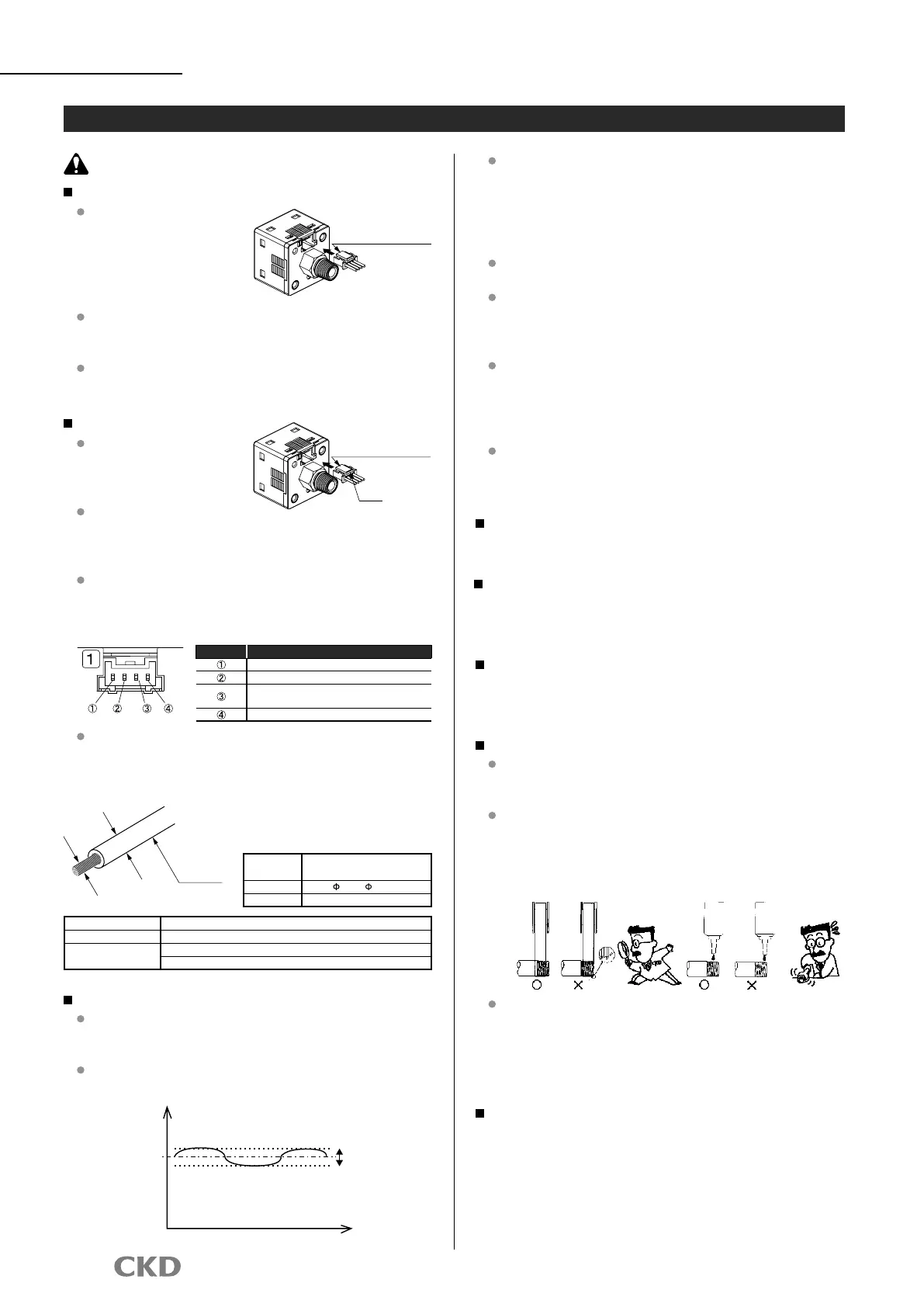

Insert cable with connector

PPX-C* into the connector

section of this product as

right when connection.

Pull out the connector

while pressing the jaw

of cable with connector

when disconnecting.

If the cable section is pulled out without pressing the jaw

when disconnecting, the cable or connector could be

broken.

Installation & Adjustment

23

CAUTION

Care must be taken for protection of body and lead wire.

Do not apply stress

to cable leading or

connector section

directly.

Cable with connector

(PPX-C*)

Do not dent or drop the body. Do not apply excessively

repeated bending force and tension to lead wire, or could

result in disconnection.

Connect an elastic material as a cable bearer to the

movable part.

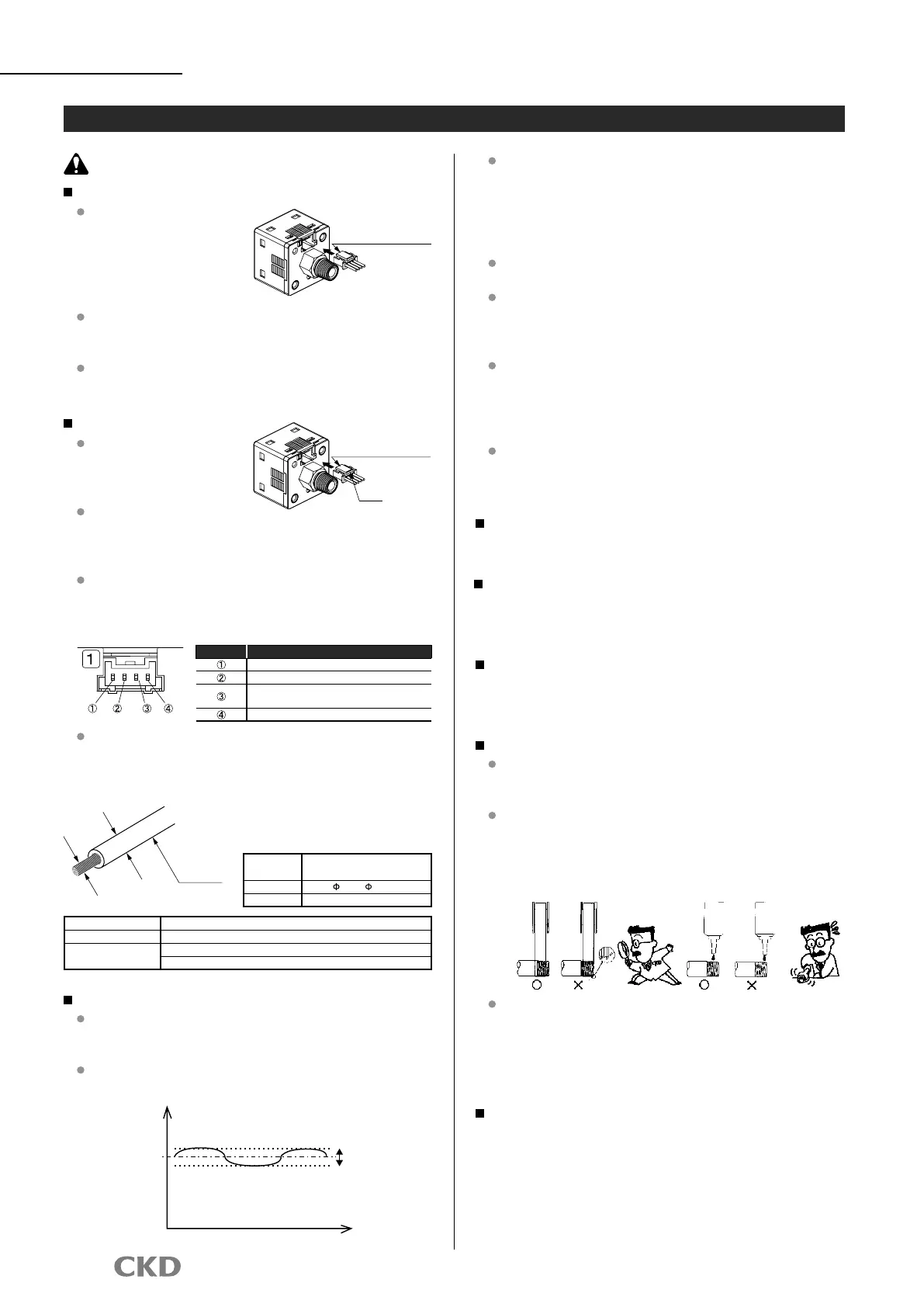

Connector wiring

<Connector pin layout drawing>

Connector pin No.

Terminal name

+V

Comparison output 1

Standard type: Comparison output 2

High function type: Analog voltage/current output or external input

0V

Use an applicable cable and crimp tools for housing and

contact if connected with the connector set (PPX-CN).

<Applicable cable>

Lead wire diameter

Lead wire

Conductor cross-section areas

Conductor cross-

section areas

0.12 to 0.32mm

2

(AWG26 to 22)

Lead wire diameter

1.0 to 1.5mm

Wire Annealed copper twist wire

Housing JST MFG CO. LTD. PAP-04V-S

Contact JST MFG CO. LTD. SPHD-001T-P0.5

Recommended

crimp tools

JST MFG CO. LTD. YC-610R (AWG26 to 24)

JST MFG CO. LTD. YC-611R (AWG22)

Wiring

Connect cable with power turned OFF. Discharge static

electricity charged in human body, tool or equipment

before and during operation.

Use stabilized power supply with ripple voltage 10% or

less without noise.

<For 24V>

Voltage

24V

Ripple ratio 10%

=10% of 24V=2.4V

2.4V

Time

Cable with connector

(PPX-C*)

Jaw

<Connector>

Contact: SPHD-001T-P0.5

Housing: PAP-04V-S

[JST MFG CO. LTD.]

Voltage must rise or fall quickly when power is turned ON

or OFF. If the rated voltage is not reached, the sensor

could malfunction. In some cases, the sensor could not

recover after the rated voltage is reached. Reset the power

in that case. Even if the voltage drops temporarily, shout

down the power once, then turn ON the power again.

Avoid use during the transient state (0.5s) when power

turned ON.

Install the product and wiring as far as possible from

noise source such as a strong electric line, etc. Take other

countermeasures for the surge from inductive loads on the

power line.

Do not operate the control unit, machinery or equipment

suddenly after wiring. Due to wrong setting, signals

not expected could be output. First stop control unit,

machinery and equipment, while energize these to test.

Set the target setting after test.

Cable with 0.3mm

2

and over can be extended up to 100m.

Note that the power line connected to this product must be

less than 10m if used as a CE marked product.

Stop machinery and equipment, and check safety

before setting switch output.

Do not turn off the power during or immediately

after the key operation setting. It may prevent

setting value from changing.

Operatethekeywithangertip.Knife,screwdriver

and other hard or pointed objects may damage the

plasticlmoverthecontrol.

Piping

Apply seal tape or sealant to screw-in joint, then screw

the joint into the port to avoid excessive torque. Apply a

spanner on the metal section to tighten.

When winding seal tape, wind the tape leaving 2mm and

over open from the thread top. If seal tape extrudes from

the thread top, seal tape chips could be created when

screwed in. These chips could enter into the circuit, and

cause malfunction.

Use pipe 1m long, and do not apply tension and impact to

the pipe. If longer pipe is used, tension not expected could

be created by the pipe weight, vibration or impact. In this

case,useanintermediatesupporttoxthepipeonthe

machine or equipment.

Do not connect relays, switches or other devices to

the output of this sensor in parallel at the PLC. Do

not short-circuit the PLC input terminal connected

to this sensor and (-) side of power to test input

devices, neither, or the output circuit of this unit

could be damaged.

Solid/

liquid

sealant

Solid/

liquid

sealant

Loading...

Loading...