14

WFK2

Series

When installing piping, align the uid ow direction

to the direction marked on the body. Connecting

the pipe in the wrong direction prevents correct

measurement of the ow rate.

Before installing piping, clean the pipes to remove

foreign matter, cutting chips, residual testing water,

etc.

Make sure that no force is applied to the resin parts

when piping.

Make sure that the self-weight of the piping is not

applied to ow rate sensor.

It may lead to damage or external leakage. We

recommend that piping be xed during operation.

Make sure that no sealing tape or adhesive enters

the pipes when connecting the piping.

When freezing may occur, take antifreezing

measures with the devices used, such as draining

the pipes of water.

If there is signicant difference between the ambient

temperature and the uid temperature, condensation

occurs, which can enter wiring parts and cause

operation failure. If condensation should occur,

ensure that the mounting orientation of the ow rate

sensor is horizontal and the display is facing upward.

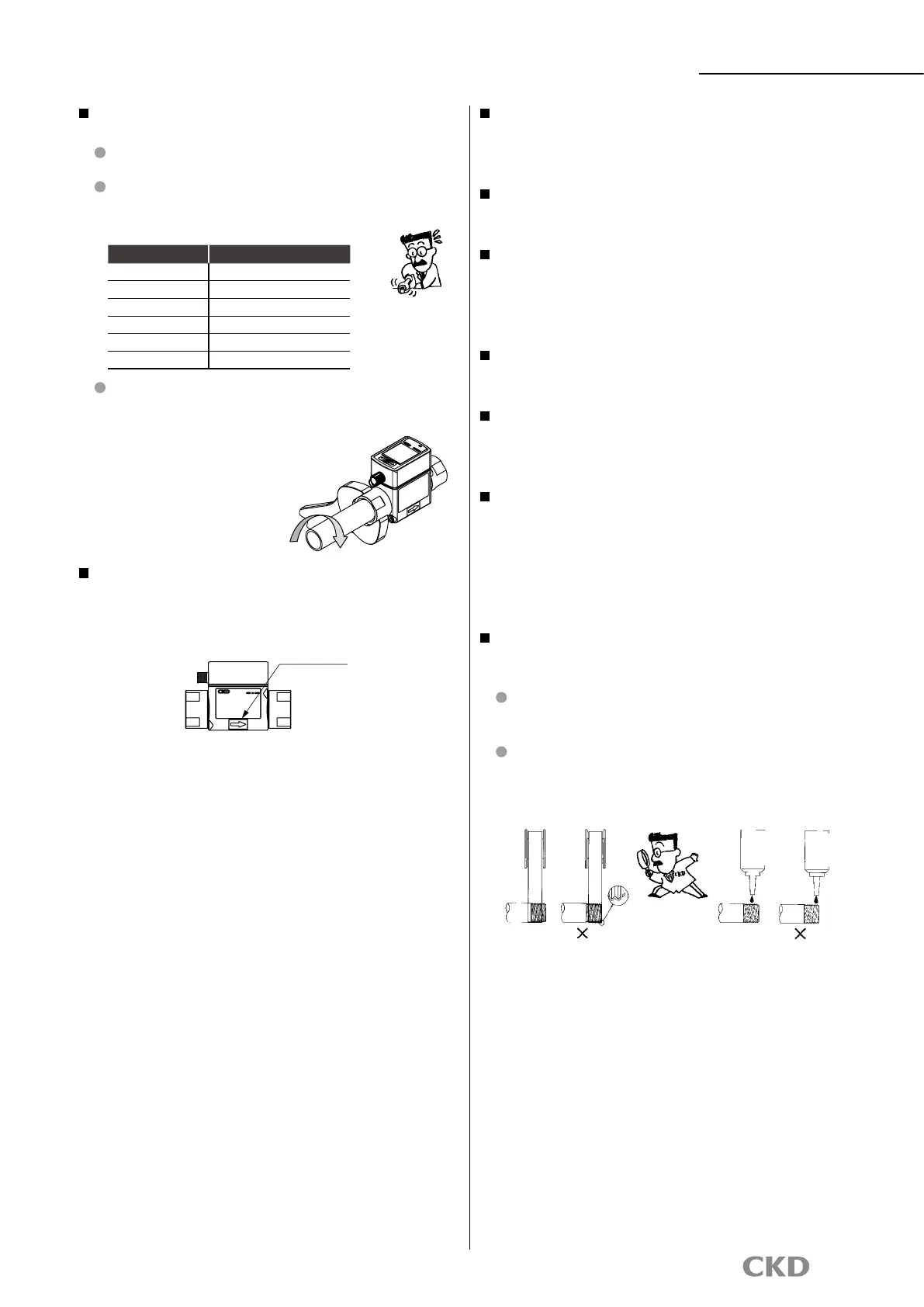

When connecting pipes, wrap sealing tape in the

opposite direction from threads starting 2 mm inside

from the end of piping threads.

If sealing tape protrudes from the pipe threads, it could be

cut when screwing the bolts in. This could cause the tape to

enter the valve, causing failures.

When using a liquid sealant, make sure it does not adhere

to resin parts. Otherwise resin parts could be damaged,

which is dangerous.

Flow direction

Use proper torque to tighten the pipes when

connecting them.

The purpose is to prevent water leakage and screw

damage.

First tighten the screw by hand to ensure that threads are

not damaged, then use a tool.

When mounting piping or ttings to this product, always

hold the attachment on the mounting side with a tool.

Holding the body of the product or the attachment on the

opposite side may lead to damage.

(Recommended values)

Port thread

Tightening torque N·m

Rc3/8 31 to 33

Rc1/2 41 to 43

Rc3/4 62 to 65

Rc1 83 to 86

Rc1 1/4 94 to 100

Rc1 1/2 104 to 108

Solid/liquid

sealant

Solid/liquid

sealant

OK

OK

Loading...

Loading...