8-10 Lift Truck Maintenance

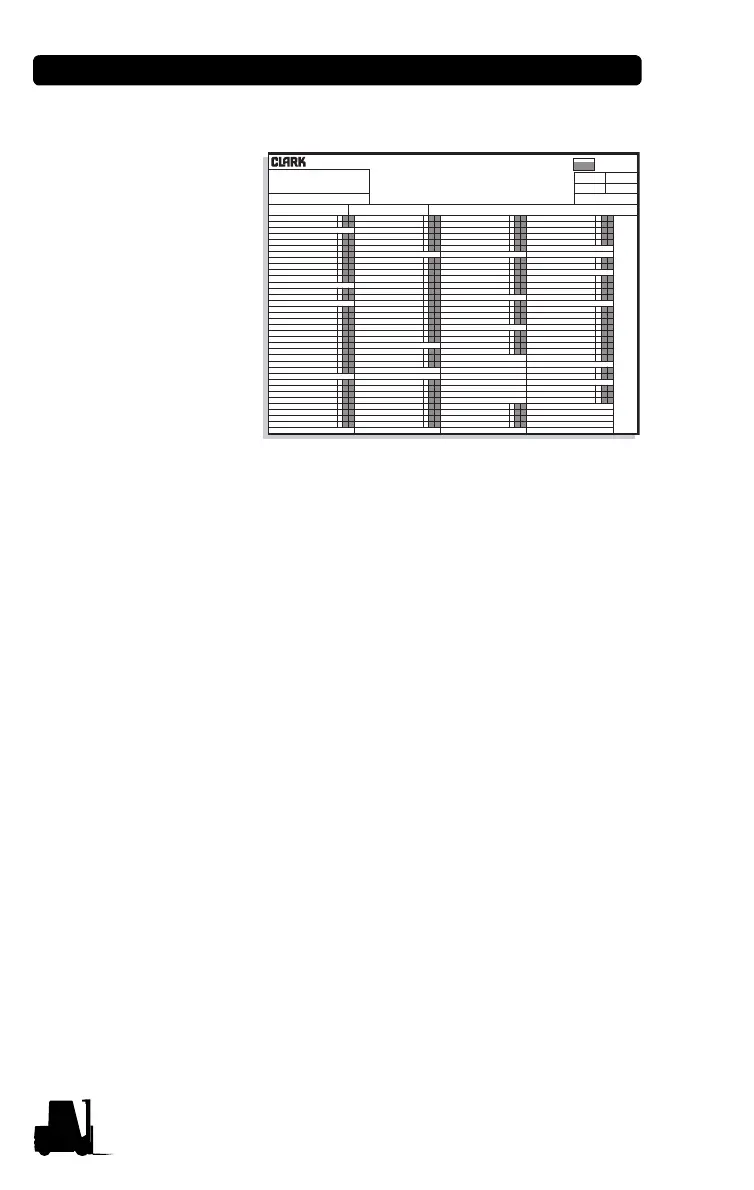

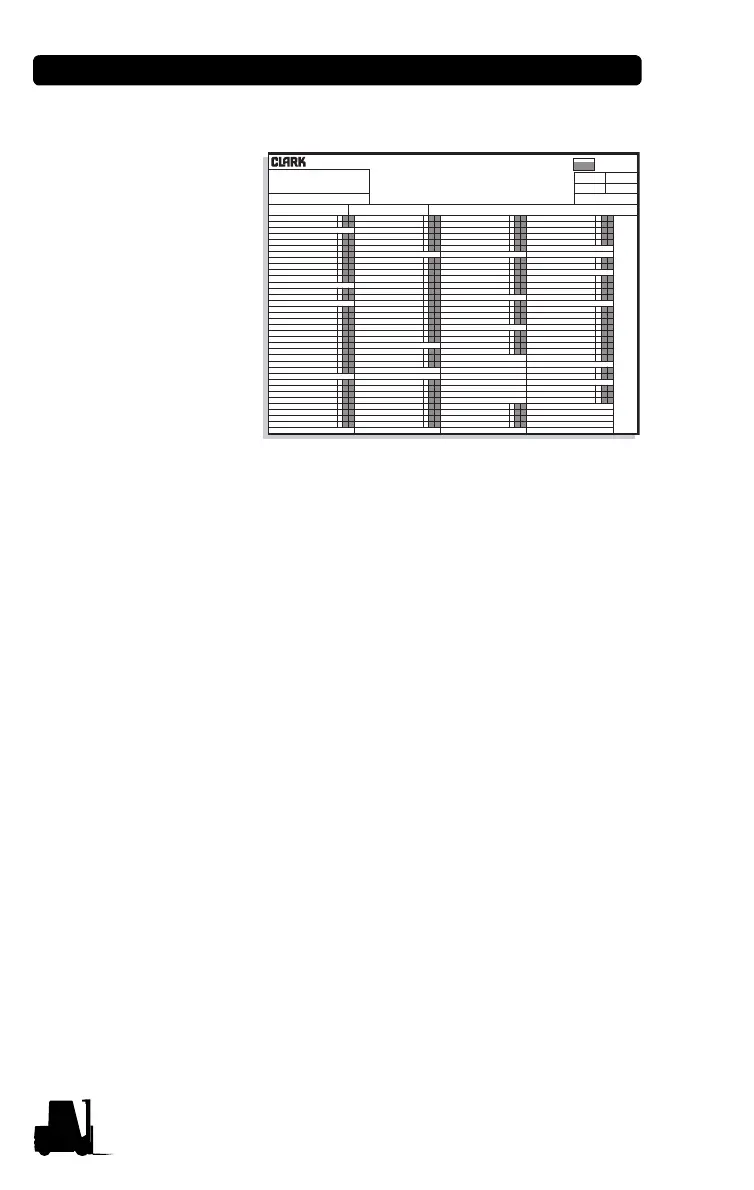

PM Report Form

A planned maintenance

(PM) program of regular,

routine inspections and

lubrication is important

for long life and trouble-

free operation of your lift

truck. Make and keep

records of your

inspections.

Use these records to

help establish the

correct PM intervals for

your application and to

indicate maintenance

required to prevent

major problems from

occurring during operation.

As an aid in performing and documenting your PM inspections,

CLARK prepared an Electric Truck Planned Maintenance Report

Form (PM Report Form). Copies of this form may be obtained from

your authorized CLARK dealer. We recommend that you use this

form as a checklist and a record of your inspection and truck

condition.

The maintenance procedures outlined in this manual are intended to

be used in conjunction with the PM Report Form. They are arranged

in groupings of maintenance work that are done in a logical and

efficient sequence.

You make check marks or entries on the PM Report Form when you

perform the PM. Please notice on the form a special coding system

for indicating the importance of needed repairs and/or adjustments.

When you have finished the PM inspections, be sure to give a copy

of the report to the designated authority responsible for lift truck

maintenance.

Do not make repairs or adjustments unless authorized to do so.

For safety, it is good practice to:

• Remove all jewelry (watch, rings, bracelets, etc.) before work-

ing on the truck.

• Disconnect the battery before working on electrical compo-

nents.

• Always wear safety glasses. Wear a safety (hard) hat in indus-

trial plants and in special work areas where protection is neces-

sary and required.

ELECTRIC TRUCK

PLANNED MAINTENACE REPORT

CUSTOMER

MODEL & SERIAL NO.

ATTACHMENT NO.

AUTHORIZED SIGNATURE

A. TEST DRIVE MACHINE 16 MOTORS 23 BRAKE SYSTEM

26 STEER AXLE

26 STEERING SYSTEM

34 UPRIGHT - CARRIAGE

34 LOAD BACK REST

35 LIFT LINKAGE (POW)

38 SHEET METAL & CWT

39 OVERHEAD GUARD

53 ATTACHMENTS

29/30 HYDRAULIC SYSTEM

32 TILT CYLINDER

19 ELECTRICAL TESTS

20 DRIVE AXLE

23 WHEELS AND TIRES

01. CLEANING & LUBRICATION

12. BATTERY AND CABLES

13. GAUGES -LIGHTS-INDICATORS

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

a. Drive Train Noise

Steering Operation

Steering Operation

c. Service Brake Operation

c. Service Brake Operation

d. Speed Control

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

e. Drive Train Noise

f. Steering Operation

g. Service Brake Operation

h. Speed Control

i. Drive Train Noise

j. Steering Operation

k. Service Brake Operation

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Drive Train Noise

e. Steering Operation

f. Service Brake Operation

g. Drive Train Noise

h. Steering Operation

e. Plugging & Direction Control

f. Return to Neutral

g. Hydraulic System Operation

e. Plugging & Direction Control

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

e. Plugging & Direction Control

f. Return to Neutral

f. Return to Neutral

g. Hydraulic System Operation

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

e. Plugging & Direction Control

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

b. Steering Operation

c. Service Brake Operation

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

e. Plugging & Direction Control

a. Drive Train Noise

b. Steering Operation

c. Service Brake Operation

d. Speed Control

e. Plugging & Direction Control

f. Return to Neutral

g. Hydraulic System Operation

h. Plugging & Direction Control

a. Security of Mounting

b. Roller Condition/Clearance

e. Chain Adjustment

g. Latch and Stop Condition

a. Conditon

a. Check for Leakage

b. Fluid Level - Condition

c. Clean/Replace Breather

d. Replace Filter

a. Check for Leakage

b. Cylinder Rod Condidtion

a. Check for Leakage

b. Cylinder Rod Condidtion

c. Mounting Security/Torque

a. Check for Leakage

b. Cylinder Rod Condidtion

c. Mounting Security/Torque

d. Tilt Cylinder Adjustment (Racking)

e. Linkage Adjustment

f. Hose Condition

g. Lift Speed (in/Sec)

h. Drift Test (in/mIn)

Full Load

Lift Cylinder

Tilt Cylinder

a. Check for Leakage

b. Fluid Level - Condition

c. Clean/Replace Breather

d. Replace Filter

e. Linkage Adjustment

f. Hose Condition

g. Lift Speed (in/Sec)

h. Drift Test (in/mIn)

Full Load

e. Plugging & Direction Control

a. Air Clean Truck

b. Air Clean Electrical Truck

Air Clean Truck

Air Clean Electrical Truck

Creep Speed

1A Operation

Creep Speed

1A Operation

INSPECTOR SPECIAL INSTRUCTIONS

DATE

DATE LUST P.M.

HOUR METER

HRS. LAST P.M.

CUST. P.O. NO.

/ = O.K

x = Adjust (Not P.M.)

r = Repair or replace

s = Requires shop year

C

O

D

E

COMMENTS

O.K.

POTENTIAL

URGENT

Loading...

Loading...