Page 11 of 49

the air discharge path, which includes any louvers,

dampers, or ducting, shall not restrict the flow of air

more than 0.3” (7.6mm) water column.

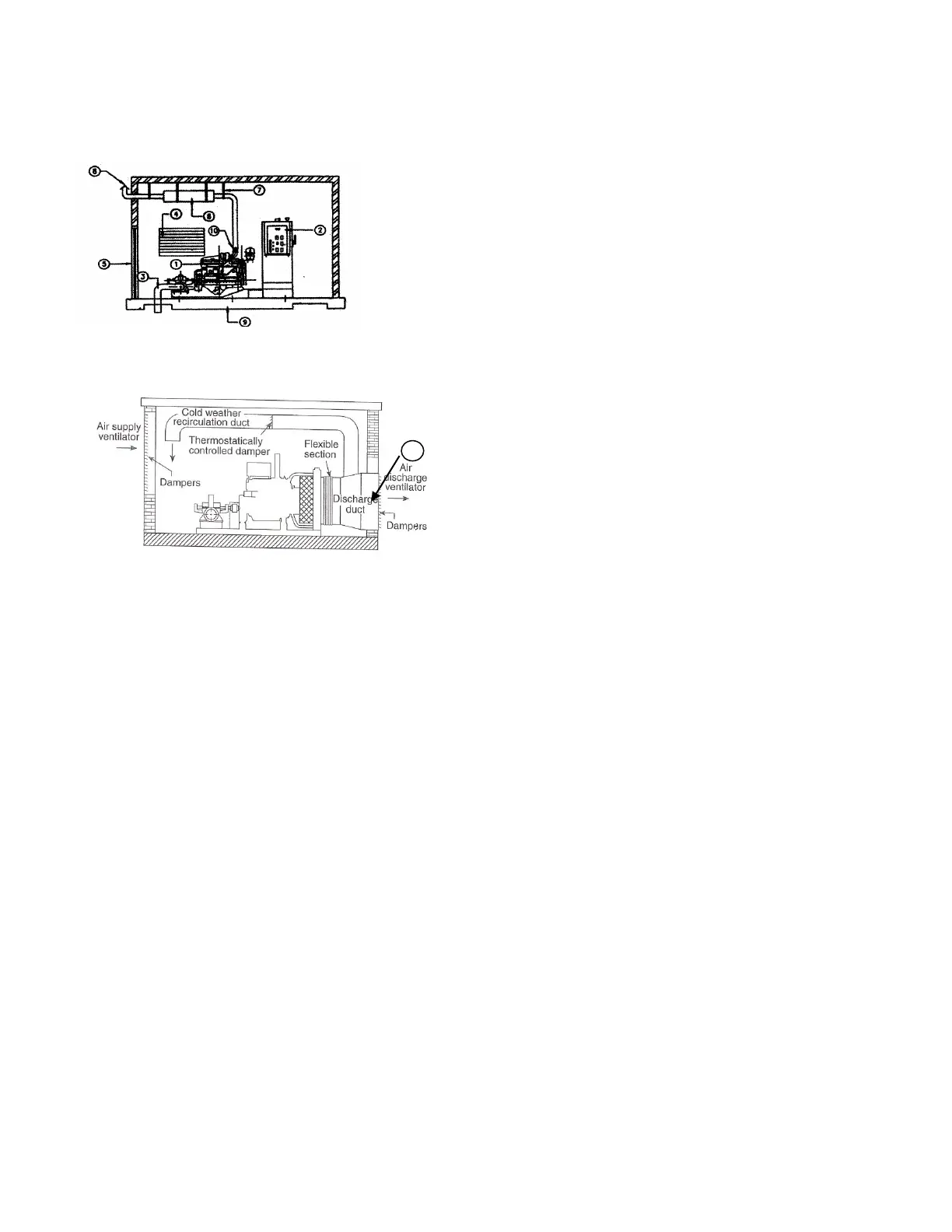

#6

Typical Installation

Heat Exchanger Cooled Engine

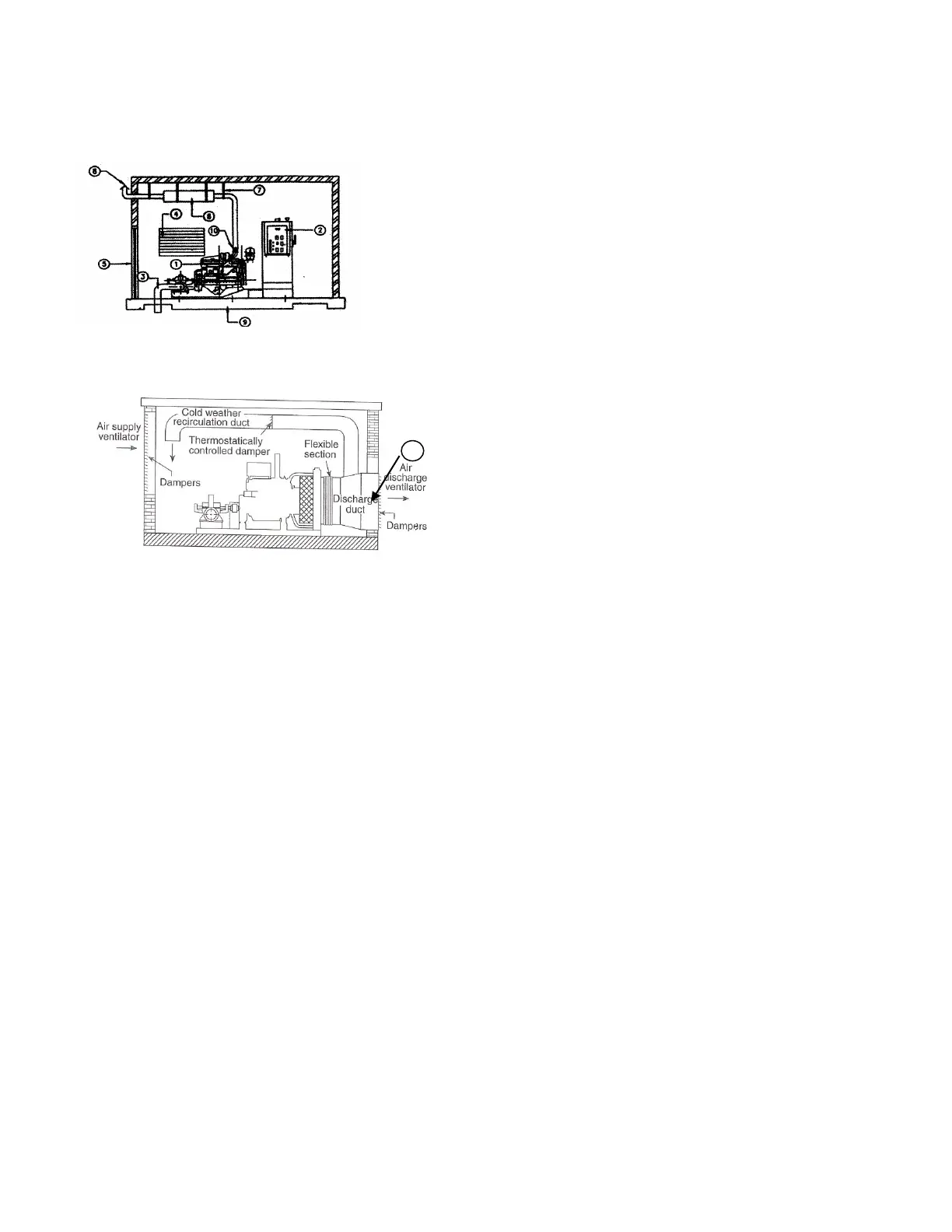

Figure #6A

Typical Installation

Radiator Cooled Engine

2.2 ENGINE STORAGE

2.2.1 Storage less than 1 year

Storing engines requires special attention. Clarke

engines, as prepared for shipment, may be stored for

a minimum of one year. During this period, they

should be stored indoors in a dry environment.

Protective coverings are recommended provided they

are arranged to allow for air circulation. The stored

engine should be inspected periodically for obvious

conditions such as standing water, part theft, excess

dirt buildup or any other condition that may be

detrimental to the engine or components.

Any such conditions found must be corrected

immediately.

2.2.2 Extended Storage Maintenance Procedure

After a one year storage period or if the engine is

being taken out of service for more than 6 months,

additional preservation service must be performed as

follows:

1) Drain the engine oil and change the oil filter.

2) Refill the engine crankcase with MIL-L-

21260 preservative oil.

3) Change the fuel filters.

4) Install the coolant plugs and install coolant in

the normal mix percentage of 50% coolant,

50% water, premixed.

5) Remove the protection from the intake and

exhaust openings.

6) Prepare a preservative fuel container as a fuel

source using a fuel conditioner mixture of

C02686 or C02687 with ONLY Diesel #2

fuel or “Red” diesel fuel (ASTM D-975) or

BS2869 Class A2. (Refer to Section 3.1.1 for

Fuel Specification.)

7) Disconnect the coupling or drive shaft from

the pump.

8) Start and run the engine at a slow speed for

1-2 minutes being careful not to exceed the

normal operating temperature.

9) Drain the oil and coolant.

10) Replace the protective plugs that were used

for shipping and storage.

11) Attach to the engine a visible card, specifying

“ENGINE WITHOUT OIL” DO NOT

OPERATE”.

IMPORTANT: THIS TREATMENT MUST BE

REPEATED EVERY 6 MONTHS

************************

PUTTING ENGINE INTO SERVICE AFTER

ADDITIONAL PRESERVATION SERVICE:

To restore the normal operation running conditions of

the engine, carry out the following:

1) Fill the engine sump with the normal

recommended oil, to the required level.

2) Remove the protective plugs used for

shipping and storage.

3) Refill cooling water to proper level.

4) Remove the card “ENGINE WITHOUT OIL,

DO NOT OPERATE”.

5) Follow all steps of the Installation

Instructions when the engine will be put into

service.

2.3 INSTALLATION INSTRUCTIONS

The correct installation of the engine is very

important to achieving optimum performance and

extended engine life.

Loading...

Loading...