Page 39 of 49

• Alarm 2: Low Oil Pressure: DP, DQ, DR, DS:

With the engine running, jumper the engine mounted

low oil pressure switch at terminal “WK” to

“GROUND”. DT only: With the engine

running, jumper the engine mounted Low Oil

Pressure switch (see Figures #33A, 33B, 34 for

location).

Wait for 15 seconds and controller alarm will

activate.

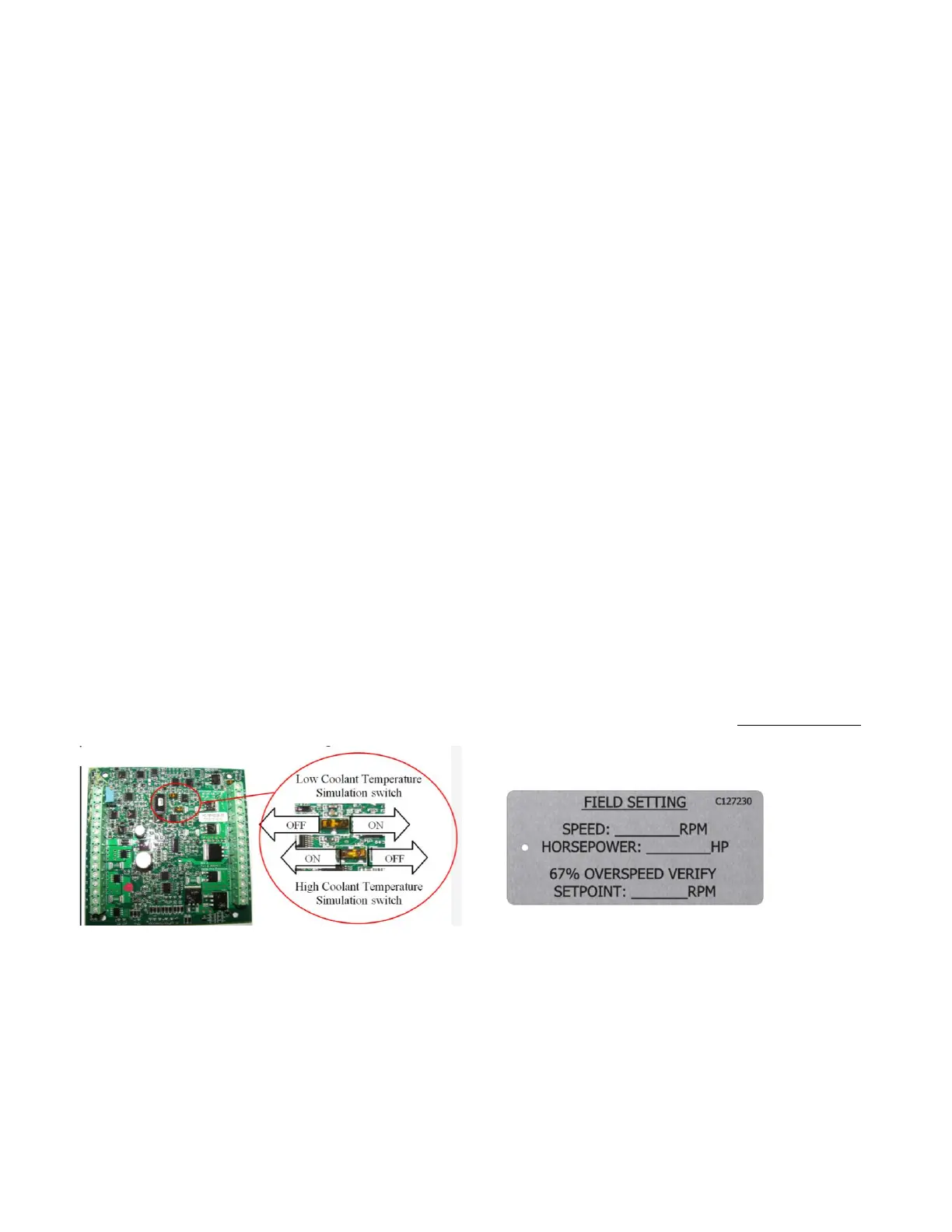

• Alarm 3: High Engine Coolant Temperature:

With the engine running, set the High Engine Coolant

Temperature DIP switch to “ON” (see Figure #36).

Use a fine pick or small screwdriver and slide the

white slider to the left. Wait for 30 seconds and

controller alarm will activate. Set white DIP switch

slider to “OFF” (right) when simulation is complete.

• Alarm 4: Low Engine Coolant Temperature: With

the engine not running, set the Low Engine Coolant

Temperature DIP switch to “ON” (see Figure #36).

Use a fine pick or small screwdriver and slide the

white slider to the right. Controller alarm will

activate immediately. Set white DIP switch slider to

“OFF” (left) when simulation is complete.

• Alarm 5: Overcrank: Use manual stop override

(ETS Governor Solenoid) to prevent the engine from

starting during the cycle-crank testing. NEVER shut

off the fuel supply to the engine to prevent it from

starting. Shutting off the fuel supply will

cause an air lock condition in the fuel system

and possibly cause fuel system component

damage.

Figure #36

3.5.7 BATTERY REQUIREMENTS

All Clarke engine models require 8D batteries, as

sized per SAE J537 and NFPA20. The battery

should meet the following criteria:

Cold Cranking Amps (CCA @ 0°F): 1400

Reserve Capacity (minutes): 430

Refer to Clarke drawing (see Page 5) for

additional information on Clarke supplied

batteries.

3.6 ENGINE SPEED ADJUSTMENT

A mechanical governor controls the engine speed.

The governor is built into the fuel injection pump. All

governors are adjusted to the rated speed at

nameplate power or maximum allowed pump load

before leaving Clarke. During Start-Up Inspection or

when placing reconditioned units into service, some

minor speed adjustment may be required. It is

recommended that this adjustment be performed by

the authorized Service Dealer representative.

To adjust the speed of the engine:

A. Start the engine by following the “To Start

Engine” Procedure in this manual.

B. Let the engine warm-up. Loosen the jam

nut(s) (Figure #37B, C, D).

C. While observing the instrument panel tach

rotate the long adjustor clockwise to lower

the RPM and counter clockwise to raise the

RPM’s until desired speed is obtained. Ref.

Figure #37B, C, D.

D. Holding secure the long adjustor with a

wrench tighten the jam nut.

E. Stop engine by following “To Stop Engine”

Procedure in this manual.

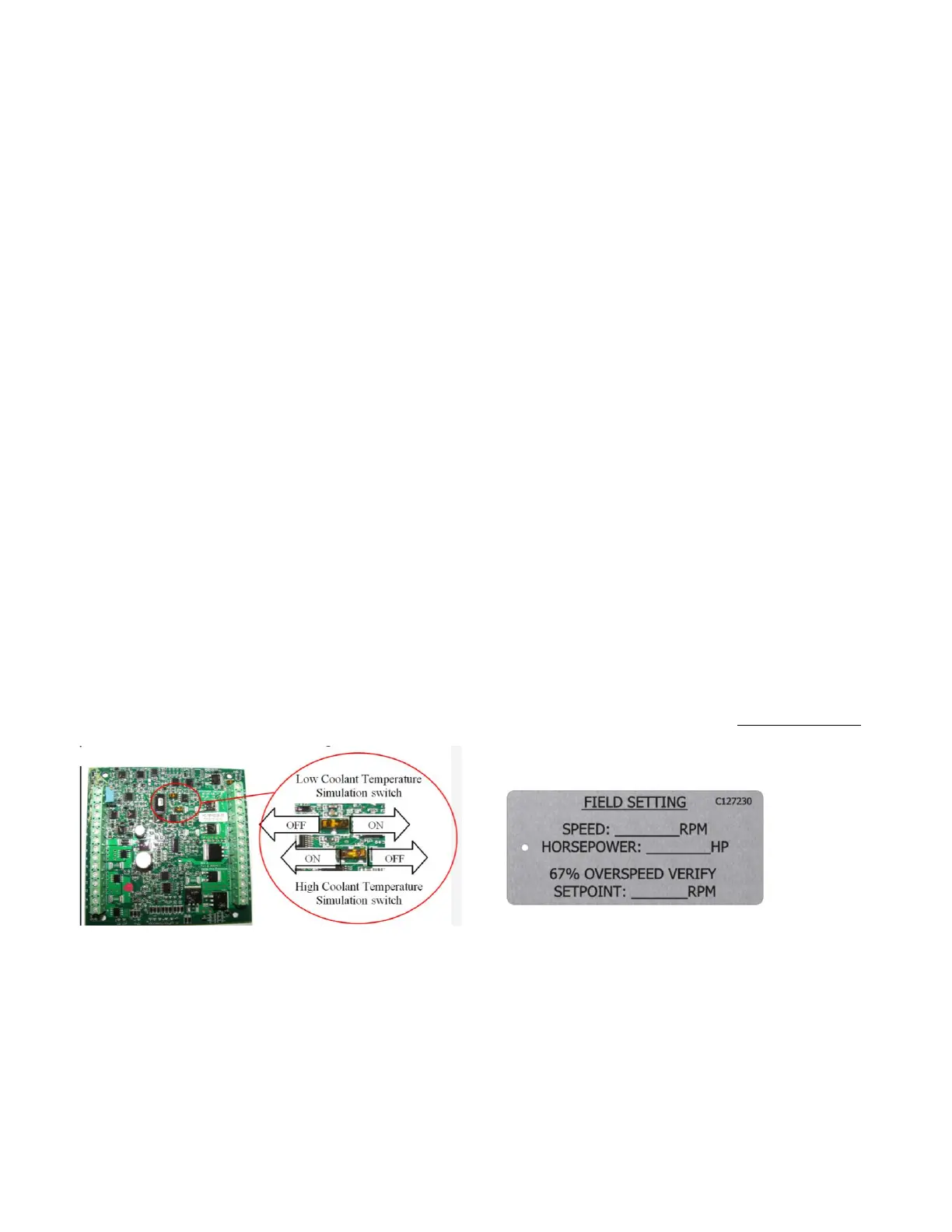

If the engine has been designed and tested for range

rating, stamp the metal tag titled “FIELD SETTING”

with the final adjusted speed, horsepower, and 67%

overspeed verify shutdown setting and keep with the

engine. Refer to Figure #38A.

Figure #38A

Loading...

Loading...