13

3.4 ELECTRICAL SYSTEM

3.4.1 Wiring Diagrams (Only with Engine Gauge

Panel)

Run/Stop

Solenoid

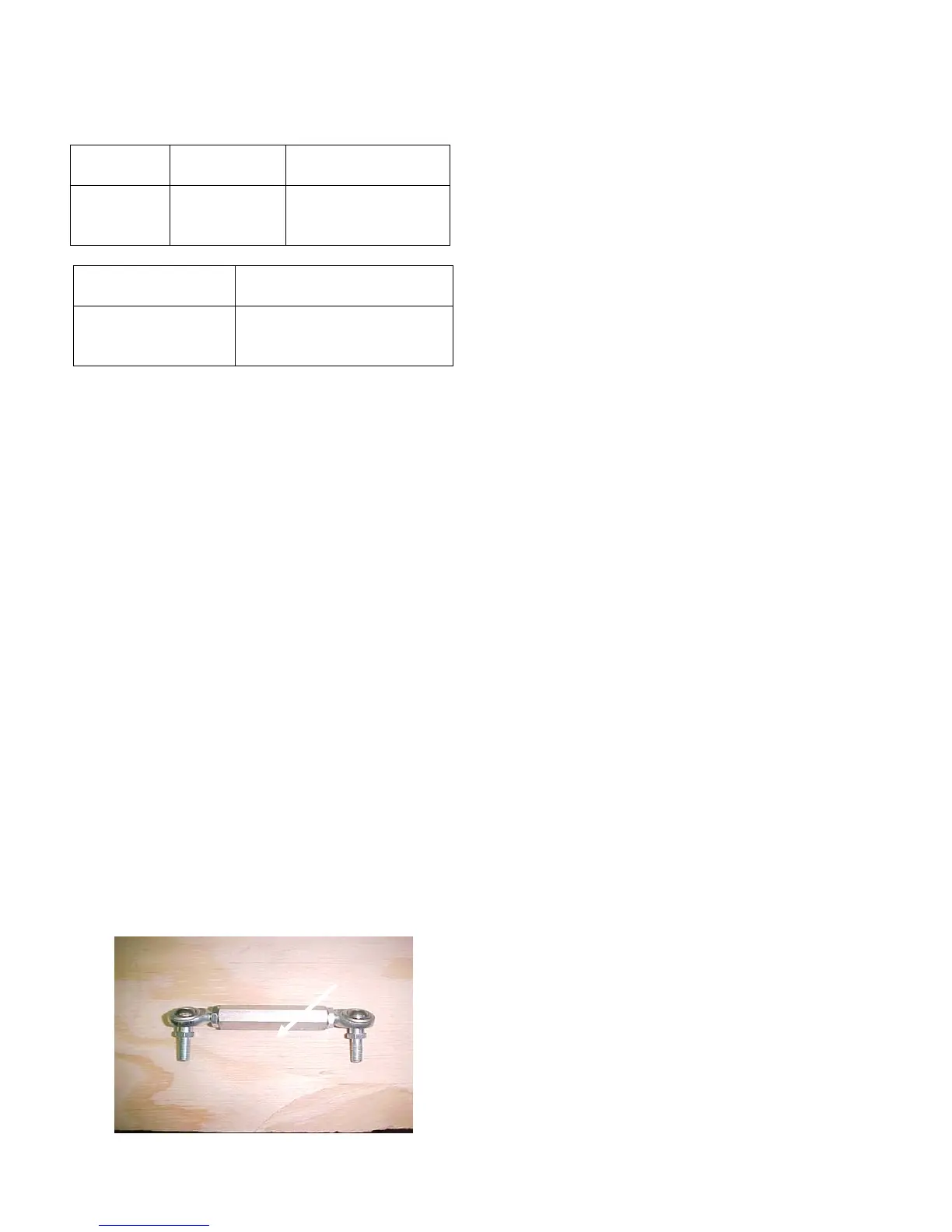

Drawing No. Description (DC

Voltage)

ETS

U071088

LPCB

Engine Gauge Panel

Drawing No. Description

(AC Voltage)

U124005 LPCB Engine Jacket Space

Heater

(NL Models - Optional)

Figure #36

3.5 ENGINE SPEED ADJUSTMENT

A mechanical governor controls the engine speed.

The governor is built into the fuel injection pump. All

governors are adjusted to the rated speed at

nameplate power or maximum allowed pump load

before leaving Clarke. During Start-Up Inspection or

when placing reconditioned units into service, some

minor speed adjustment may be required. It is

recommended that this adjustment be performed by

the authorized Service Dealer representative.

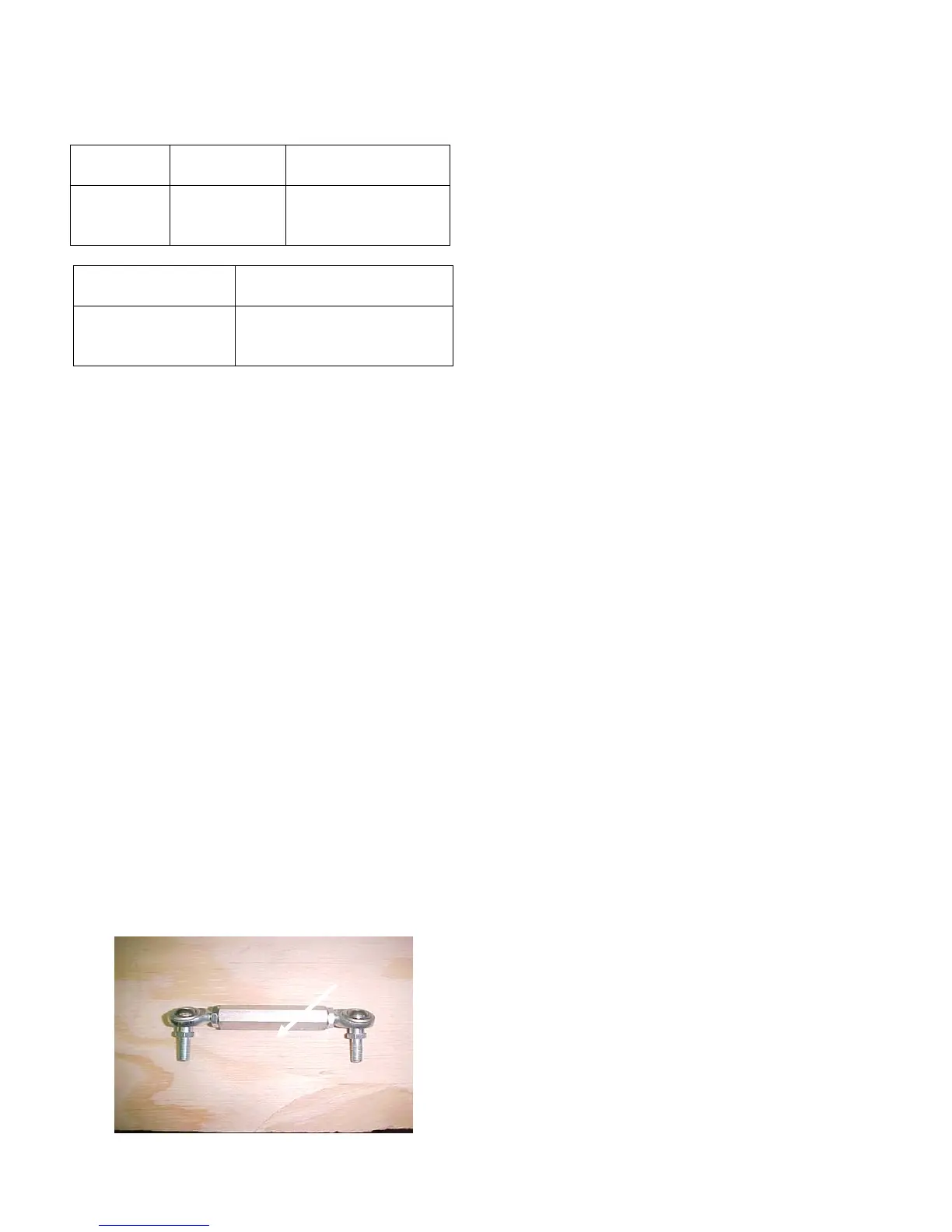

To adjust the speed of the engine:

A. Start the engine by following the “To Start

Engine” Procedure in this manual.

B. Let the engine warm-up. Loosen the jam

nut(s) (Figure #38).

C. While observing the instrument panel tach

rotate the long adjustor clockwise to lower

the RPM and counter clockwise to raise the

RPM’s until desired speed is obtained. Ref.

Figure #38.

D. Holding secure the long adjustor with a

wrench tighten the jam nut.

E. Stop engine by following “To Stop Engine”

Procedure in this manual.

Figure #38

4.0 MAINTENANCE SCHEDULE

4.1 ROUTINE MAINTENANCE

NOTE: The following Routine Maintenance schedule

is based on an engine usage rate not exceeding 2

hours per month.

LEGEND:

Check

Clean

Replace

o Lubricate

WEEKLY

Air Cleaner

Battery

Cooling Water Solenoid Valve

Exhaust System

Fuel Tank

General Inspection

Governor Run-Stop Control

Space Heater

Lubrication Oil Level

Operating Gauges

Run Engine

EVERY 6 MONTHS

Batteries

Cooling Water Strainers

Fuel Lines

EVERY 1 YEAR

Air Cleaner

Crankcase Vent System

Fuel & Oil Filters

Lubricating Oil

Mounting Isolators

Wiring System

EVERY 2 YEARS

Air Cleaner

Batteries

IMPORTANT: Set main pump controller to “OFF”

while servicing engine. Before turning the main

pump controller to the "OFF" position, check with

the maintenance and security supervisors to verify

that all the departments concerned will be alerted of

the temporary interruption of their fire protection

equipment for normal maintenance or testing. Also,

alert the local fire department in the event that the

main pump controller is connected by silent alarm to

headquarters. When servicing is complete, return

main pump controller selector to "Automatic"

position and the mode selector on the engine to

“Automatic” position. Advise the appropriate

personnel the engine has been returned to the

“Automatic”.

Loading...

Loading...