4

© Copyright 2020. All rights reserved.

FUSI O N TRE A TMEN T S Y STEM

450

GALLONS/DAY

800 GALLONS/DAY

BLO W ER SE R V I C E P ART S

COMPLETE BLOWER: P/N 5250-0050-A

BLOWER DIAPHRAGM: P/N 152949-A

BLOWER FILTER: P/N 152950-A

MFG.DATE:

Manufacturer:

Clarus Environmental • 3649 Cane Run Road

Louisville, KY 40211•1-800-928-7867

toll free

ZF 450

ZF 800

□

□

®

Certified to

NSF - ANSI

Standard 40

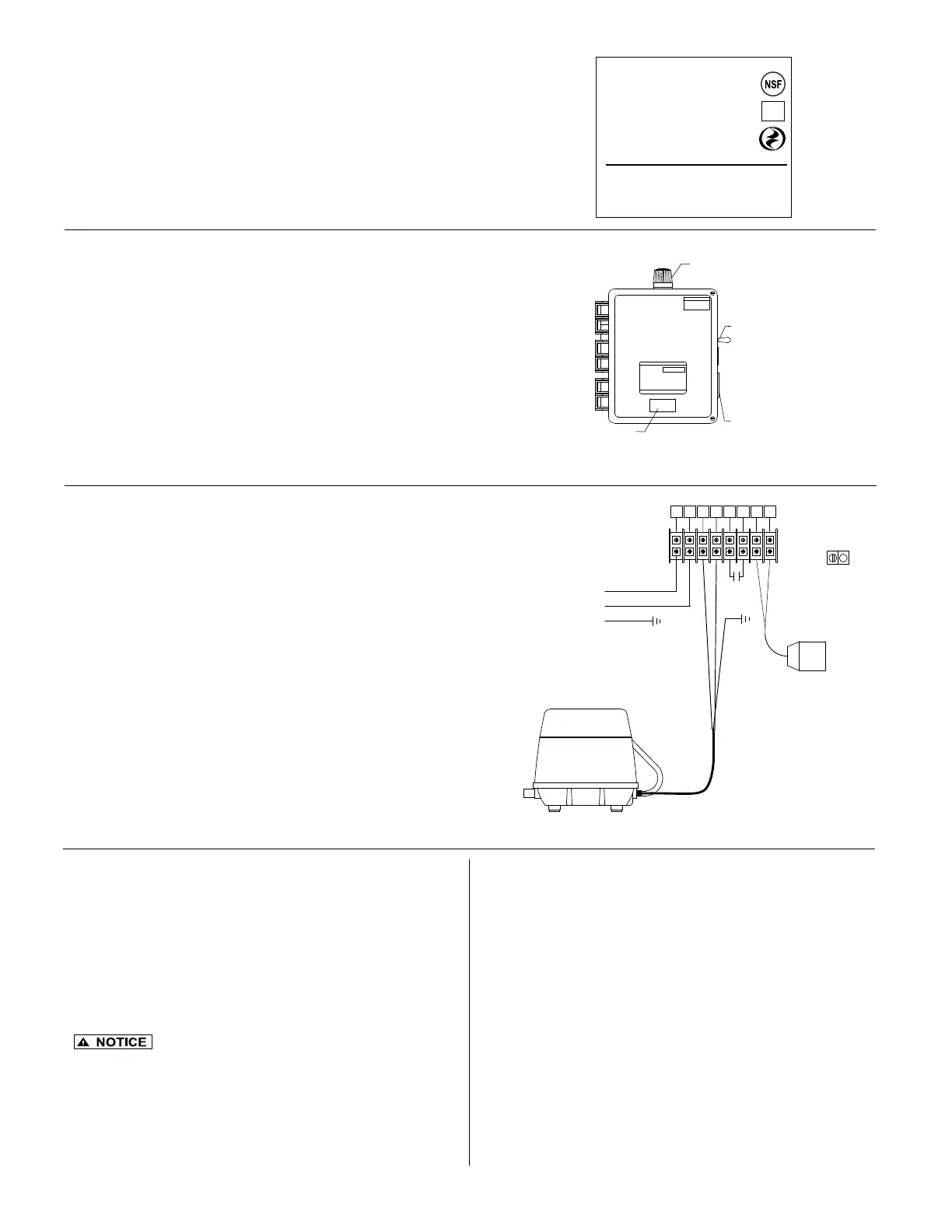

The Fusion

®

utilizes an alarm panel (see Figure 6) that is designed to

activate an audible buzzer and red beacon light on top of the panel if

there is a drop in air pressure, if a high water alarm condition occurs,

or if the blower does not cycle between recirculation and backwash

modes within the preset time. (Note: Alarm panel can only function

as long as there is electrical power supplied to the panel)

You may from time to time check the proper operation of the alarm

panel by toggling the black switch on the side of the panel to “test”.

The buzzer will sound and the red beacon will light as long as you

hold the switch in the test position. Release the switch for normal

operation.

A dataplate similar to the one in Figure 5 is located on the blower

housing and the alarm panel. There is important information about

the Fusion

®

on the dataplate, such as the part number, model

number, serial number, and hydraulic capacity. Please make a note

of this information for future reference or in case you should need to

contact your Fusion

®

maintenance provider.

The contracting installer must mark the installed model number on

the dataplate, the blower housing and the alarm control panel.

Figure 6

P/N

WARNING!

RED BEACON

SILENCE/TEST

SWITCH

BUZZER

FUSION

DATAPLATE

sk2649

LEAKY FIXTURES

It is very important to monitor all water xtures in the home for leaks and

drips and repair them immediately. Leaks can cause tremendous water

use and may hydraulically overload your Fusion

®

system and reduce

its treatment efciency. Excessive water use may also overload your soil

absorption eld and cause failure.

HIGH USE WATER DEVICES

The draining of hot tubs and swimming pools into your Fusion

®

system

will cause hydraulic overloading and will impair the treatment efciency.

Please drain these devices to another location. Contact your local

regulatory authorities or authorized Fusion

®

maintenance provider for

more information. The use of large capacity single ll and drain whirlpool

bathtubs may also cause hydraulic overloading of your Fusion

®

. Please limit

the use of these types of tubs.

The Fusion

®

system is designed to continuously operate automatically with

little direct maintenance from the owner. Periodically, a check of the blower

area is recommended to ensure no debris obstructs the ventilation or intake

areas of the blower. Also, periodically test the control panel as outlined under

the alarm panel section. The owner should closely monitor the types and

amounts of substances and products used. Water use should also be closely

monitored to ensure proper operation of the Fusion

®

system.

Periodically, more extensive maintenance must be performed. Your authorized

Fusion

®

maintenance provider will oversee this service. The name of the

maintenance provider can be recorded on the front of this document and should

also be located on the alarm panel. For more information see the Operation and

Maintenance section of the manual.

The owner should only perform minimal routine maintenance on the Fusion

®

such as clearing debris from around blower housing (leaves, snow, and grass

clippings). The Fusion

®

should also be protected from excessive weight such

as vehicular trafc. Trees and bushes should not be planted in close proximity

to the Fusion

®

. The Fusion

®

should be accessible to maintenance personnel

and the riser lids must never be buried.

ALARM PANEL

DATAPLATE

FLOODING

If ooding of the Fusion

®

occurs and the blower or the

alarm panel is submerged, please disconnect power at the circuit breaker.

DO NOT try to reconnect power to either the blower or alarm panel once

it has been submerged. Immediately contact your authorized Fusion

®

maintenance provider to inspect the Fusion

®

, the blower, and the alarm

panel. Your maintenance provider will repair or replace the components as

needed.

Figure 5

SYSTEM CARE

sk2933

Figure 7

1

2 3 4 5 6 7 8

TB2

120 VAC L1

INCOMING N

POWER GND

DISNF

ALARM

HIGH WATER

ALARM

BLOWER

*FOR ILLUSTRATION PURPOSES ONLY*

REFER TO SCHEMATIC LOCATED IN

PANEL FOR INSTALLATION

BLOWER FOR ZF-450 AND ZF-800

GND LUG

The Fusion

®

system is designed to function even if wastewater does not

enter it for extended periods of time. The power to the blower must remain

on during this time for the system to function properly. Weekend use will

not harm the system as long as the blower is on. Should seasonal use

require a complete shut down of the property, then it is recommended that

the blower be turned off. It is important to start up the system in advance of

actual occupancy to allow for normal treatment to resume. Please contact

your authorized Fusion

®

maintenance provider for further information

concerning shut down and startup of the Fusion

®

. You may also contact

your maintenance provider for the shut down and startup services.

INTERMITTENT USE

Loading...

Loading...