3

© Copyright 2020. All rights reserved.

The NSF mark displayed here will

be on all NSF Standard 40, Class

1 certied Fusion

®

systems. The

Fusion

®

models ZF-450 and ZF-

800 will have the mark displayed

on the alarm panel. Systems not

NSF Standard 40, Class 1 certied,

will not display the mark.

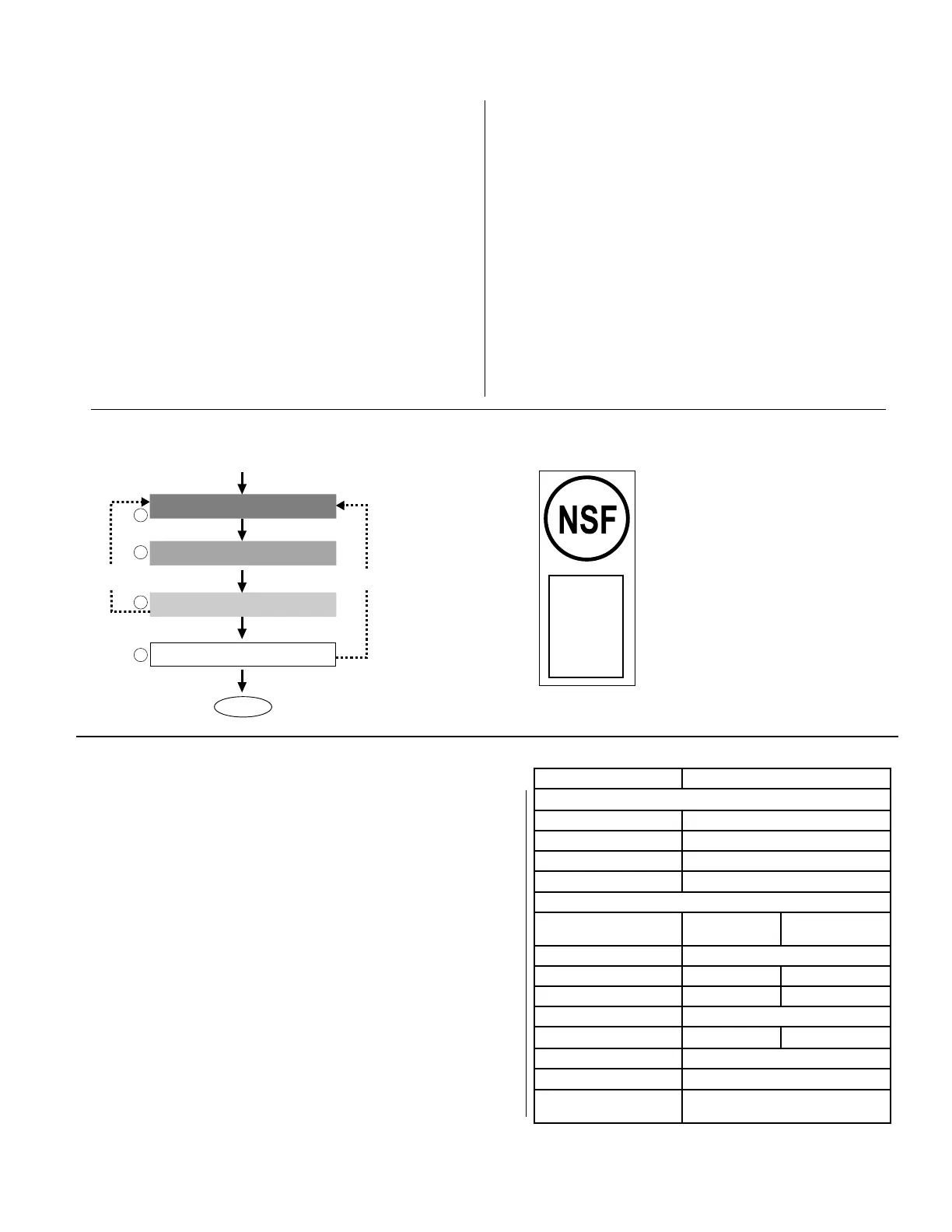

Back-Wash

Recirculation

Sedimentation Chamber

Anaerobic Chamber

Aeration Chamber

Storage Chamber

Effluent

Inflow

1

2

3

4

Figure 3 - Treatment Flow of the Fusion

®

System.

PROCESS DESCRIPTION

1. Sedimentation Chamber

This chamber is designed to physically separate solids

from the incoming water. Scum is the oating material and

sludge is the material that has settled at the bottom.

2. Anaerobic Chamber

This chamber contains a spherical skeleton-type lter

media, 4.3 inch diameter (109 mm). Through bacterial

growth processes on the surface of the lter media,

biological anaerobic treatment thrives while suspended

solids are captured. Furthermore, the microorganisms

in this chamber convert nitrates in the recirculated water

returning from the aerobic chamber to gaseous nitrogen.

The gaseous nitrogen then escapes to the atmosphere.

3. Aeration Chamber

The aeration chamber consists of an aerated upper section

and a lter media lower section. The chamber is lled with

hollow, cylindrical lter media, 0.6 inch diameter (15 mm)

and 0.55 inches long (14 mm). Biological treatment takes

place on the lter media surface. Aeration is continuous.

Residual suspended solids are captured by the lter media

circulating in this section. During normal operation, a

recirculation line transfers water back to the sedimentation

chamber.

The lter media in the aeration chamber are backwashed

regularly (twice a day, 5 or 10 minute cycle) by the

backwash system located at the bottom of the chamber.

The accumulated sludge is transferred back into the

sedimentation chamber for further digestion.

4. Storage Chamber

This chamber is designed to temporarily store treated water

exiting the aeration chamber. This treated water is ready for

discharge.

The complete wastewater treatment system will typically consist of

the Fusion

®

treatment components and a soil absorption eld for nal

disposal of the liquid efuent. Some states or counties may require the

addition of a septic tank before the Fusion

®

to increase the sedimentation

chamber capacity and retain more solids. Please see Figure 11 for a

typical Fusion

®

system. Variations to the typical system will be made

to suit your particular site and system design needs. Please contact

your authorized Fusion

®

installer or maintenance provider for further

information about your system design.

®

Certified to

NSF/ANSI

Standard 40

Class 1

Performance

Designation

Figure 4

NSF STANDARD 40, CLASS 1,

CERTIFICATION MARK

The Fusion

®

treatment unit utilizes an electronic, dual-port blower

designed specically for use with this system. The blower consists

of a linear motor and two diaphragms to generate the air ow

necessary to aerate and recirculate water within the system. This

style of blower is quieter and more efcient than traditional rotary

vane compressors. Once installed and adjusted, circuitry within the

blower will automatically switch the unit from normal recirculation

mode to backwash mode and back again when appropriate. In the

event of a power outage, the blower will stop, but a backup battery

within the unit will retain the correct time and backwash settings.

THE FUSION

®

DUAL-PORT BLOWER

SYSTEM COMPONENTS

Blower Part # 5250-0050

RATING

Voltage AC120V

Frequency

60Hz

Insulation class A Rank

Operating time Continuous

CHARACTERISTICS AND PERFORMANCE

Solenoid Valve

off

Solenoid Valve on

Voltage(V) AC120V

Current (A) 1.8 or less 2.0 or less

Power consumption (W) 71 ± 20% 77 ± 20 %

Air volume (L/min) 80 ± 10%

Leak air volume(%)

1.0 or less 2.0 or less

Noice level (dBA) 43.0 or less

Valve movement (N/L) 75.0 or less

Temperature rise

60 deg or less at 30 °C room

temperature

Loading...

Loading...