&MGPEVDU.5

9.10 Anomalies - Remedies

5IFJOUFSWFOUJPOTNVTUCFDBSSJFEPVUCZBRVBMJGJFEJOTUBMMFSPS ZBTQFDJBMJTFETFSWJDFDFOUSF

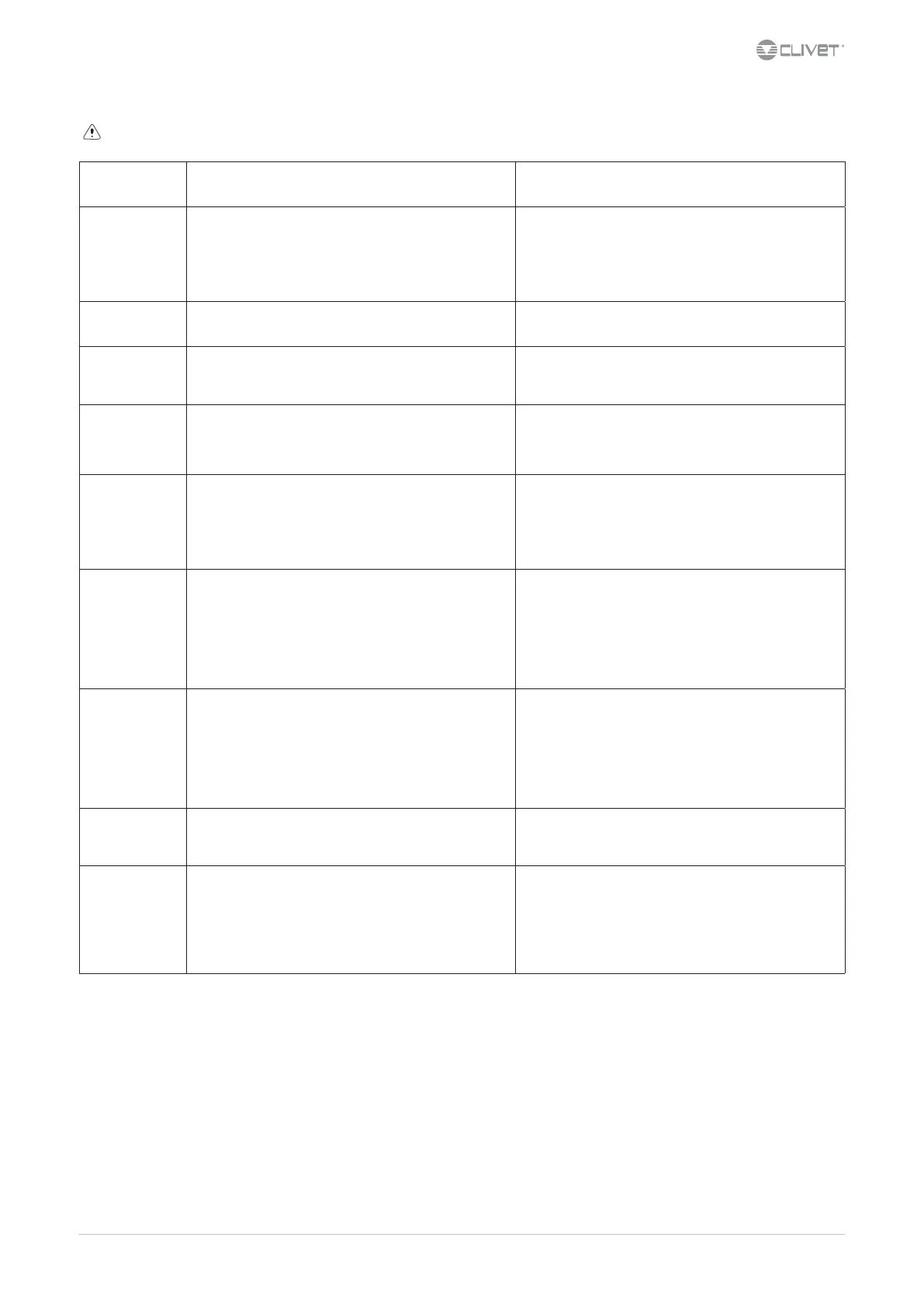

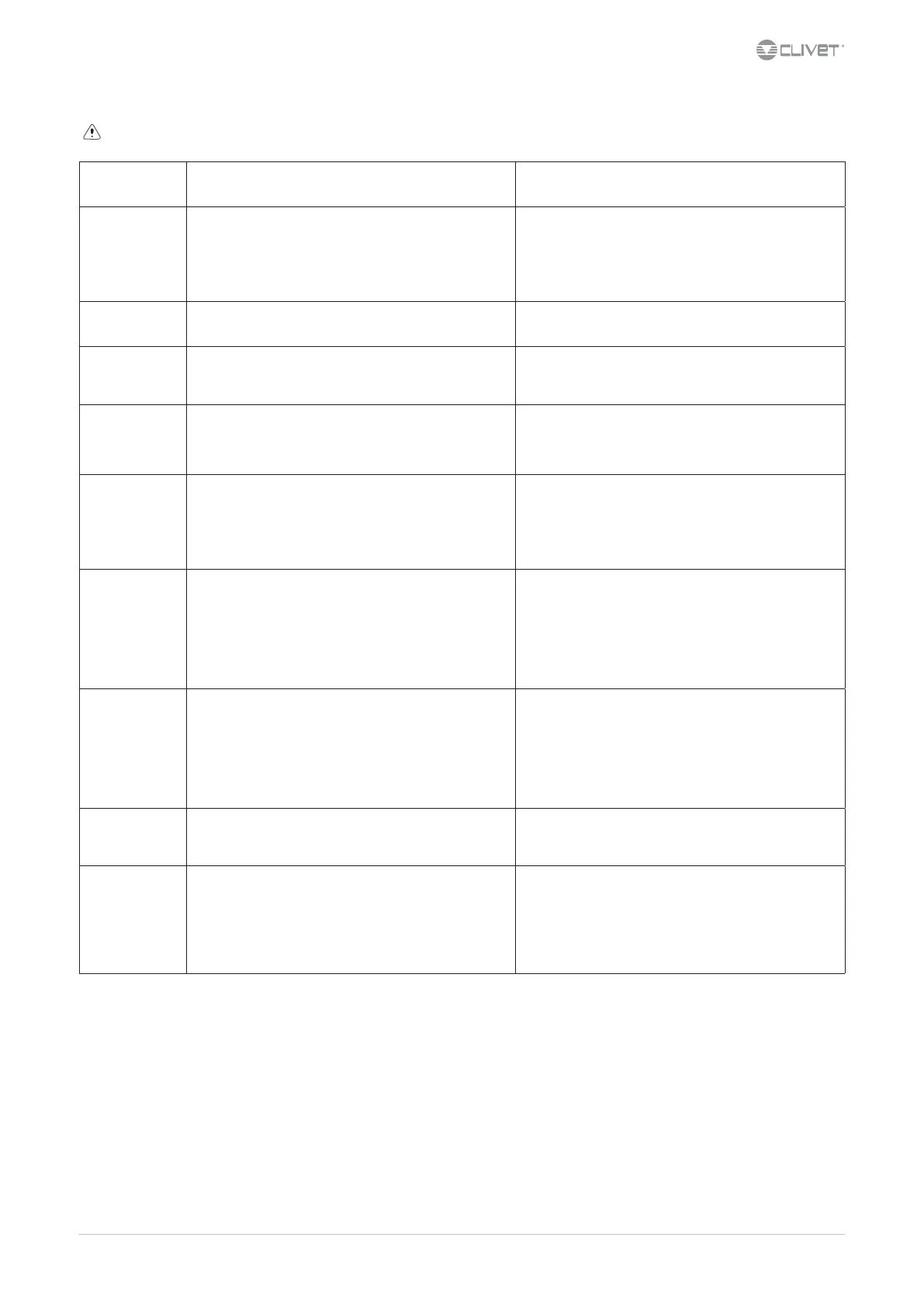

Eect Cause Remedy

Feeble air discharge

Wrong speed setting on the control panel

Obstructed air lter

Obstruction of the airow (inlet and/or outlet)

Air distribution system load loss has been underestimated

Sense of rotation inverted

Select the right speed on the control panel

Clean the air lter

Remove the obstruction

Increase fan speed

Check wiring diagram and electrical connections

Excessive air ow Air distribution system pressure drop has been overestimated Reduce fan rotation speed and/or create pressure drop in ducting

Insucient static

pressure

Rotation speed too low

Sense of rotation inverted

Increase fan speed

Check wiring diagram and electrical connections

Excessive noise

Excessive air ow

Metal components damaged

Rotation parts o balance

Reduce air ow

Check state of components and replace damaged parts

Balance fan impeller

The motor/fan does

not work

Current lack

With water low temperature thermostat “TM” has tripped because

the temperature has dropped below 40°C (in winter mode)

Make sure that

Make sure that

Control the power supply

Control the boiler

The electrical power is on - Switches and/or thermostats are on the

right working position

No objects obstruct the fan rotation

The unit does not

heat up as before

Hot water supply lack

Wrong setting on control panel

Make sure that

Make sure that

Make sure that

Control the boiler and the hot water pump

See control panel settings

The air lter and the coil are clean

Air did not enter in the water circuit, check it using provided air vent

valve

The installation is well balanced - The boiler is functioning - The hot

water pump is functioning

The unit does not

cool up as before

Chilled water supply lack

Wrong setting on control panel

Make sure that

Make sure that

Make sure that

Control the chiller and the chilled water pump

See control panel settings

The air lter and the coil are clean

Air did not enter in the water circuit, check it using provided air vent

valve

The installation is well balanced - The chiller is functioning - The

chilled water pump is functioning

Water entrainment

Siphon is clogged

No siphon

Clean siphon

Fit a siphon

Condensate on the

external structure of

the unit

Temperature and humidity limit conditions (indicated in the Techni-

cal Bullettin - operating limits) have been reached

Condensate water draining problems

When the requested environment temperature is reached the fan

stops while chilled water is still circulating in the coil

Race the water termperature over the minimum limits mentioned in

the Technical Bulletin

Check the drain pan and the drain pipe

Provide a regulation where water supply is stopped when environ-

ment temperature is reached (fan stop) - (3 way valve – 2 way valve

– pump OFF – Chiller OFF, etc.)

Loading...

Loading...