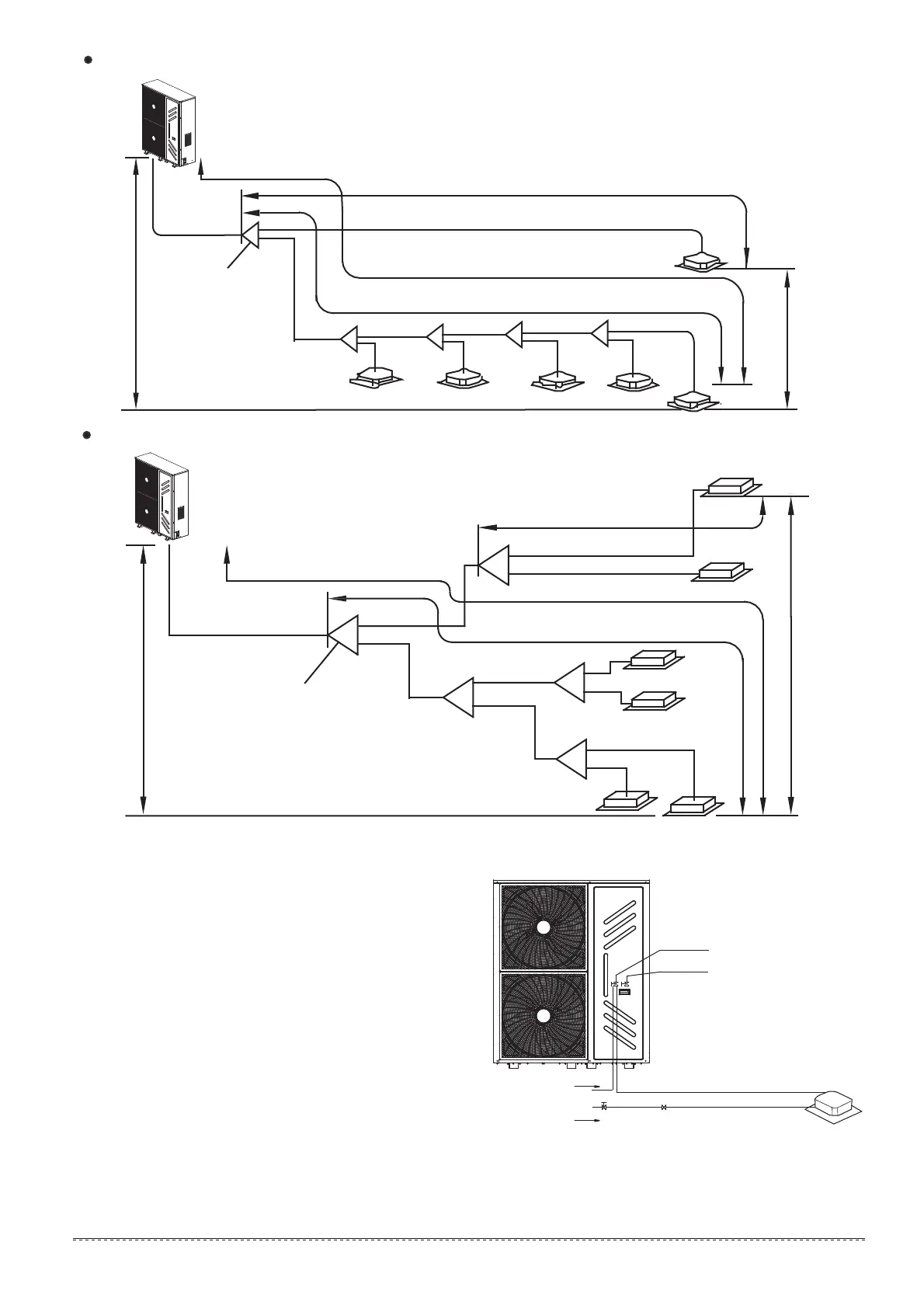

Fig.5-6

D

$

/

/

%

&

'

(

/ / /

E

F

G

HI

The first connecting methond

Outdoor unit

Pipe length(From the nearest branch pipe equivalent length)

Drop HEIGHT between indoor unit

and uutdoor unit

The first manifold

Maximum pipe equivalent length

(From the first line branch pipe) Maximum pipe equivalent length

Indoor Unit to Indoor

Unit Drop Heihgt

Indoor Unit

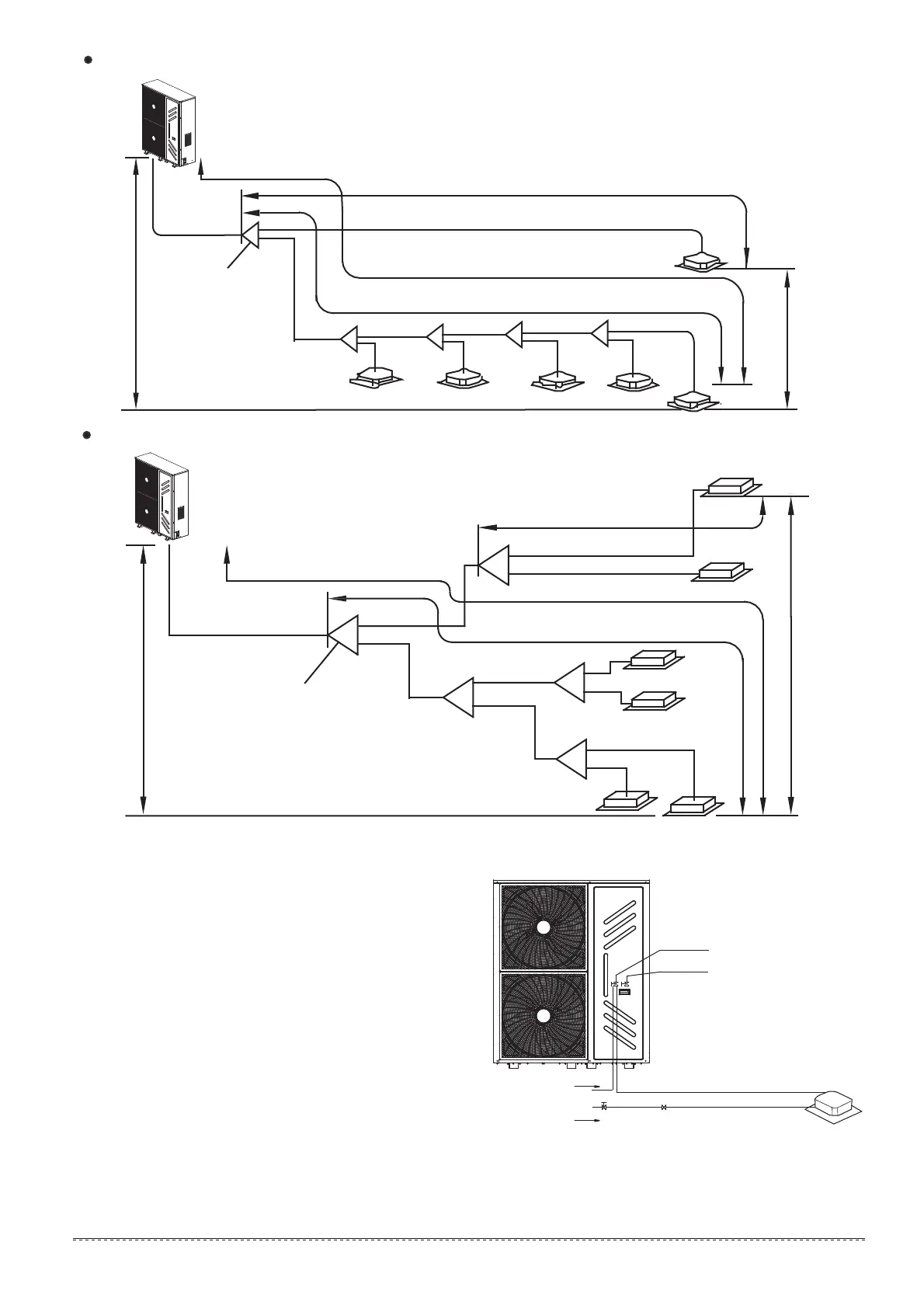

Fig.5-7

D

1

1

1

1

1

1

$

%

'

(

&

E

F

H

I

G

/

/

/

/

/

The second connecting methond

Outdoor unit

Drop HEIGHT between indoor unit

and uutdoor unit

Indoor unit farthest pipe equivalent

length

The First manifold

Pipe length(From the nearest manifold

equivalent length)

(From the first manifold)

Maximum pipe equivalent length

Indoor Unit to Indoor Unit Drop Heihgt

Indoor unit

5.6 Remove Dirt or Water in the Pipe

1. Make sure there is no any dirt or water before connecting the

pipe to the outdoor units.

2. Wash the pipe with high pressure nitrogen, never use

refrigerant of outdoor unit.

5.7 Airtight Test

1. Connect the high pressure side pipe and liquid side stop valve

after connecting indoor unit pipes.

2. Weld low pressure side pipe and meter connector.

3. Use vacuum pump to discharge air from valve core of liquid

side stop valve and meter connector until the pressure reaches

to -1kgf/cm

2

.

4. Close the vacuum pump and fill nitrogen40kgf/cm

2

.

5. At the end of air tightness test, the gas side stop valve and

the low pressure side piping should be welded.

Fig.5-8

Liquid side stop valve

Gas side stop valve

Nitrogen

Nitrogen

Liquid pipe

Gas pipe

Indoor unit

Meter connector components

used for pressure bulge test

06$1;0L77 ,QVWDOODWLRQPDQXDO

Loading...

Loading...