2

GENERAL INFORMATION

SPECIFICATIONS

The Valustar Electric Chain Hoist is a highly versatile materials

handling device that can be used to lift loads that are within

rated capacity. The mechanical features of these hoists

include an alloy steel lift wheel, overload device (Protector),

hardened steel chain guides, simple two stage gear reduc-

tion, lifetime lubrication, forged steel hooks and lightweight

aluminum frames. The electrical features include hoist-duty

motor, magnetic reversing contactor, rugged control station,

heavy-duty motor brake and control transformer (3 phase

units). Hoists are supplied with a rigid upper hook suspension

as standard. Table 1 summarizes the hoist’s specifications.

CM REPAIR/REPLACEMENT POLICY

All Columbus McKinnon (CM) Valustar Electric Chain Hoists

are inspected and performance tested prior to shipment. If

any properly maintained hoist develops a performance prob-

lem, due to a material or workmanship defect, as verified by

CM, repair or replacement of the unit will be made to the

original purchaser without charge. This repair/replacement

policy applies only to Valustar Hoists installed, maintained

and operated as outlined in this manual, and specifically

excludes parts subject to normal wear, abuse, improper

installation, improper or inadequate maintenance, hostile

environmental effects and unauthorized repairs/modifications.

We reserve the right to change materials or design if, in our

opinion, such changes will improve our product. Abuse,

repair by an unauthorized person, or use of non-CM replace-

ment parts voids the guarantee and could lead to dangerous

operation. For full Terms of Sale, see Sales Order

Acknowledgement. Also, refer to the back cover for

Limitations of Warranties, Remedies and Damages, and

Indemnification and Safe Operation.

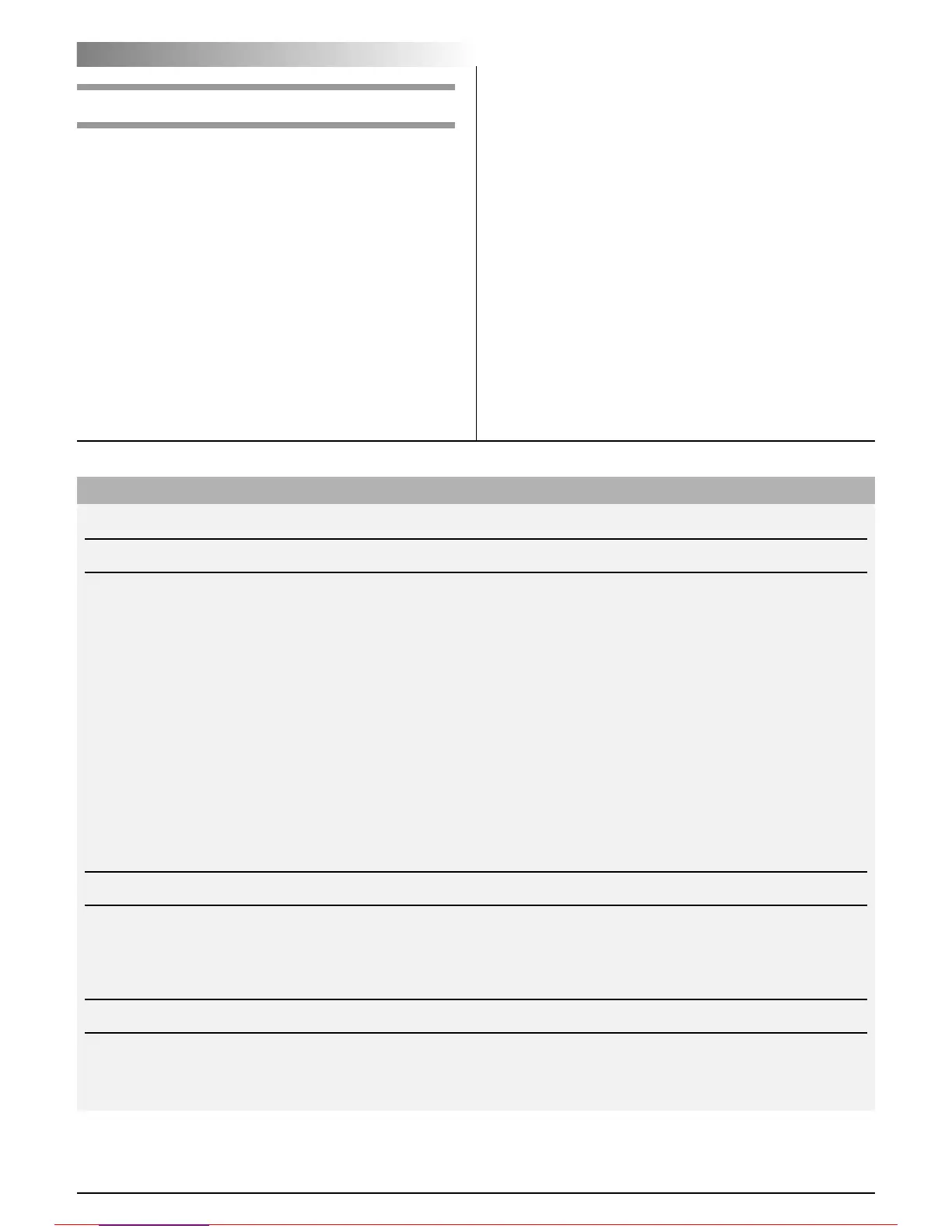

Valustar Electric Chain Hoist Specifications

DC MAX. CAP. LIFTING SPEED MOTOR MIN. HOOK POWER SUPPLY NET WEIGHT

CODE CODE MODEL (TONS) F.P.M. H.P. DISTANCE VOLTS/PHASE/HERTZ (POUNDS)

2401 62401 WB 1/4 16 1/4 16-1/2" 115-1-60 51

2402 62402 WB 1/4 16 1/4 16-1/2" 230/460-3-60 61

2413 62413 WE 1/2 8 1/4 19-7/8" 230/460-3-60 72

2412 62412 WE 1/2 8 1/4 19-7/8" 115-1-60 62

2403 62403 WF 1/2 16 1/2 16-1/2" 115-1-60 53

2404 62404 WF 1/2 16 1/2 16-1/2" 230/460-3-60 68

2405 62405 WH 181/2 19-7/8" 115-1-60 69

2406 62406 WH 181/2 19-7/8" 230/460-3-60 78

2414 62414 WJ 1/2 32 1 17-5/8" 230/460-3-60 105

2407 62407 WL 1 16 1 17-5/8" 115-1-60 109

2408 62408 WL 1 16 1 17-5/8" 230/460-3-60 106

2409 62409 WR 28124-1/2" 115-1-60 129

2410 62410 WR 28124-1/2" 230/460-3-60 126

Series 635 Low Headroom Trolley Specifications

MAX. CAP. TREAD DIA. OF MIN. RADIUS

(TONS) FOR USE WITH MODELS ADJUSTABLE FOR S-BEAMS WHEELS (IN.) CURVE (IN.)

1/4 to 1 WB, WE, WF, WH, WJ, WL 4" X 7.7# TO 15" X 50# 3-1/8 24

2 WR 6" X 12.5# TO 18" X 54.7# 4-3/4 24

Series 635 Motor-Driven Trolley Specifications

MAX. CAP. POWER TRAVEL MOTOR ADJUSTABLE MIN. RADIUS

(TONS) FOR USE WITH MODELS SUPPLY SPEED (FPM) H.P. FOR S-BEAMS CURVE (IN.)

1/4 to 2 WB, WE, WF, WH, WJ, 115-1-60 75 1/4 6" x 12.5" 30

WL, WR 230-3-60 thru

or 460-3-60 15" x 50#

Table 1

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com

Loading...

Loading...