7

ENGLISH

3. Assembly

Attach thewheels using thefastening pieces provided in thebag: washers, axle spindle, andpins.

3.1 Preparations

1. Placethelog splitter on firm, level surface providing acomfortable working height. Ensure that there is

adequate lighting for thework to be carried out safely.

2. Plugthemains lead into anelectrical socket, preferably via anRCD. Takecare to position themains lead

where it will not hinder thework or be damaged by thework with thelog splitter.

3. Unscrew thebleed screw (7) 3 or 4 turns to ensure adetectable flow of air to theoil tank while thelog

splitter is in operation.

3.2 Setting the desired splitting length

Thelog splitter returns to theset splitting length automatically. Thesplitting length can be set by using areturn

stop which prevents thepiston from returning all theway.

1. Runthepiston out without apiece of wood, release thepower switch (11) but hold thepiston in

theextended position using thecontrol lever (1).

2. Undothereturn stopscrew.

3. Movethereturn stop to thedesired splitting length and tighten thescrew.

3.3 Operating the log splitter

1. Always place theleast knotty end of thelog toward thewedge,

always split along thegrain.

2. Position thelog in such away that it is stable, use thelog retaining

plate tohelp.

3. Startthemotor by pressing and holding in thepower switch (11).

4. Startthehydraulic ram by depressing thecontrol lever (1) (with

thepower switch pressed in).

5. Thepressure plate (3) will force thelog against thesplittingwedge.

6. Release thecontrol lever (1) and thepower switch (11) to end

thesplitting operation once thelog has beensplit.

Note: Thepressure plate will automatically stop at about 8 cm /

3inches before it reaches thewedge.

• Note: Ifthewood does not start to split after 5 seconds despite full pressure, release thecontrollever and

thepower switch and let thepressure plate return to thestarting position. Turnthelog through 90 degrees

and try to split itagain.

• Note: Makesure that thebleed screw (7) is closed before thelog splitter is moved or put away, otherwise oil

could leakout. If thebleed screw is left open when thelog splitter is stored away, theoil will absorb moisture

from theair. Thiscan cause thehydraulic system to rust from theinside.

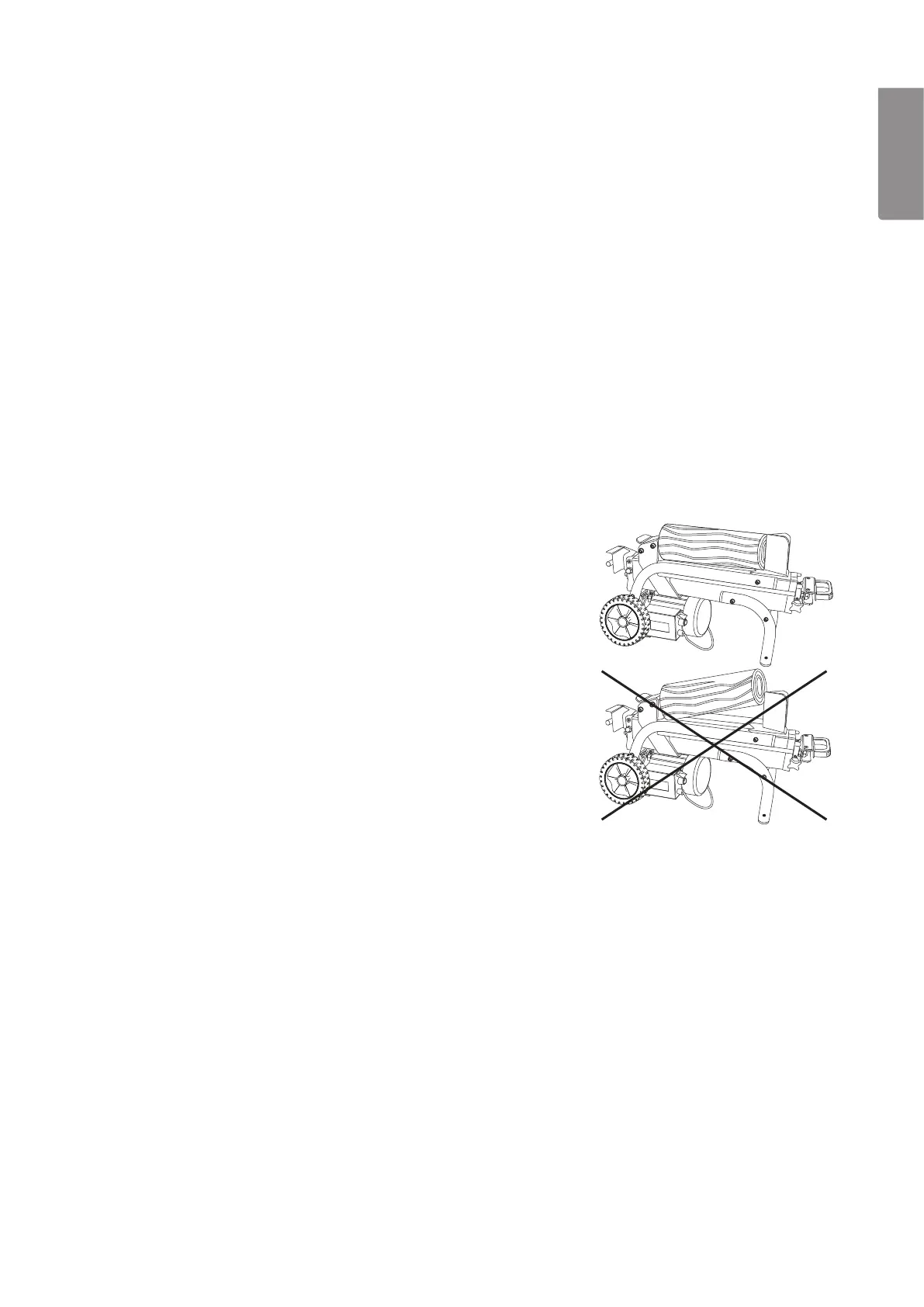

• Note: Donot use just thetop half of thewedge for splitting, thelog splitter can be damaged by unbalanced

loading.

Loading...

Loading...