9

ENGLISH

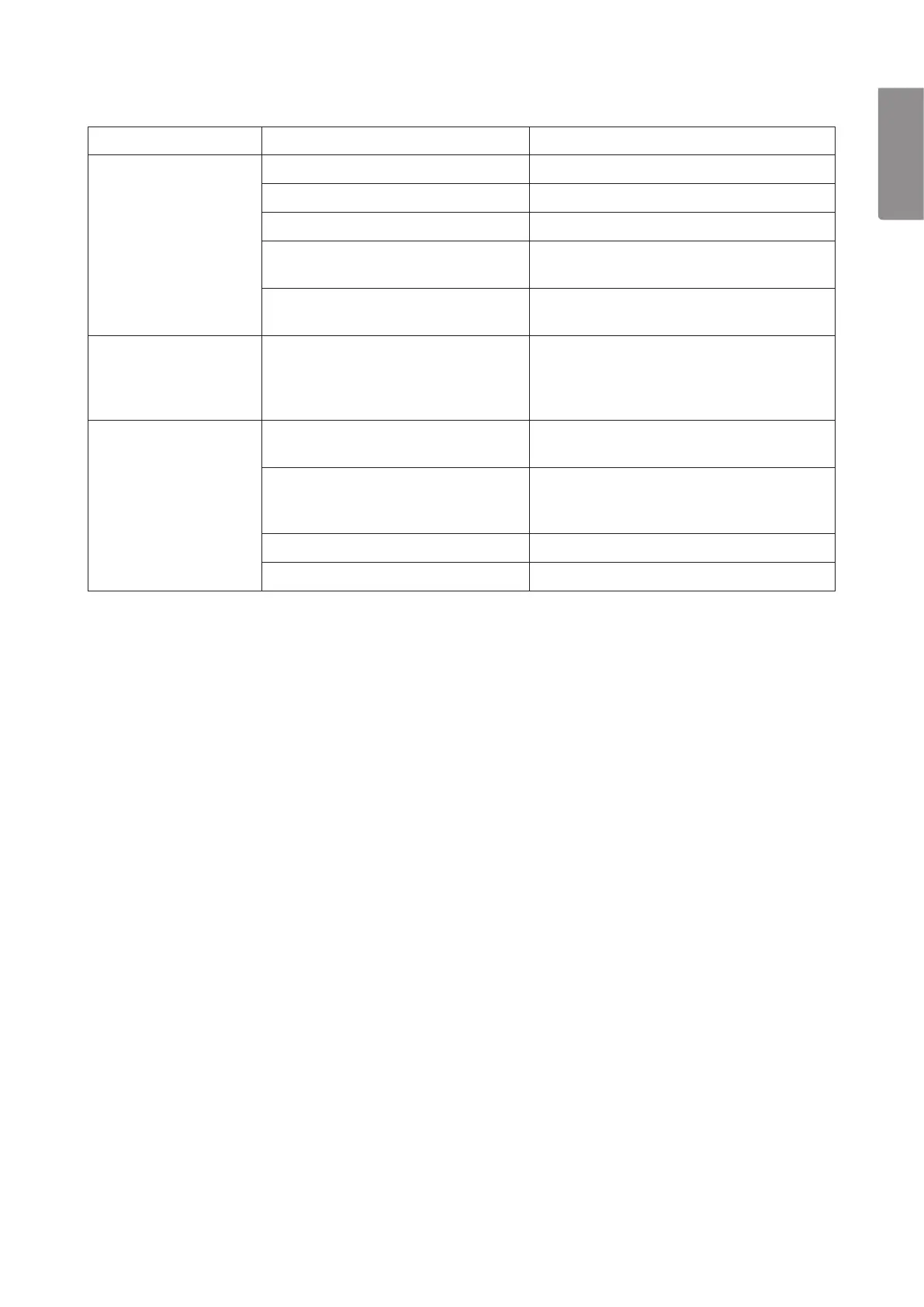

6. Troubleshooting

Problem Possible cause Remedy

Fails to splitlog. Log improperly positioned. Turn thelog around or rotateit.

Thelog is too big or toohard. Reduce thesize of thelog before splitting.

Thewedge is blunt or damaged. Sharpen thewedge (refer to Maintenance).

Oil leakage. Localise theleak, have aqualified

mechanic fix theleak.

Incorrect pressure limiting screw

setting.

Have aqualified mechanic adjust

thepressure setting.

Pressure plate moves

jerkily, makes strange

noises and vibrates

heavily.

Lack of oil, air in thesystem. Check theoil level and refill if necessary.

Checkforleaks.

Oil leak around piston

or other component.

Air trapped in system during

operation.

Loosen thebleed screw 3–4 turns before

startingwork.

Thebleed screw has not been

tightened before thelog splitter

wasmoved.

Tighten thebleed screw before moving

thelog splitter.

Theoil drain bolt is not properlytight. Tighten theoil drainbolt.

Thehydraulic valve or gasket isworn. Contact theretailer.

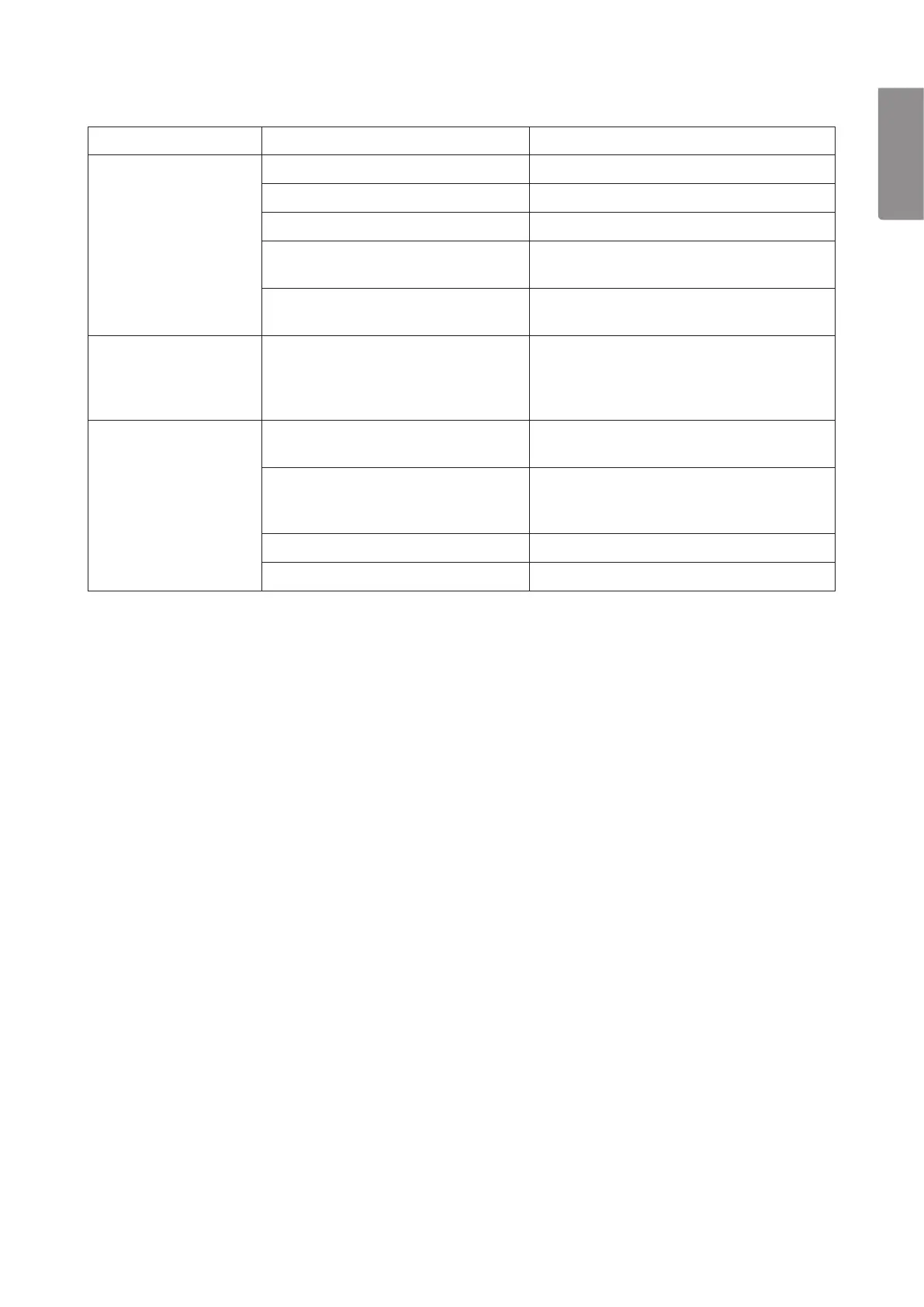

7. Specifications

Motor 230V AC, 50Hz

Power 1500 W

IP rating IP54

Log capacity* Ø 5–25cm, length: 15–37cm

Recommended

operating temperature +5 to +40 °C

Splitting pressure 4 tonnes

Oil capacity 3.5 litres

Dimensions Length: 840mm

Width: 360mm

Height: 470mm

Weight 40kg

Adjustable returnstop 160–370mm

* Thestated splitting capacity is indicative and depends on thehardness, diameter and knottiness of thewood.

Itis usually possible to split far larger diameterlogs.

Loading...

Loading...