22 • Important: Always read and follow the operating instructions.

Duckhead (Mount/Demount Tool Head)

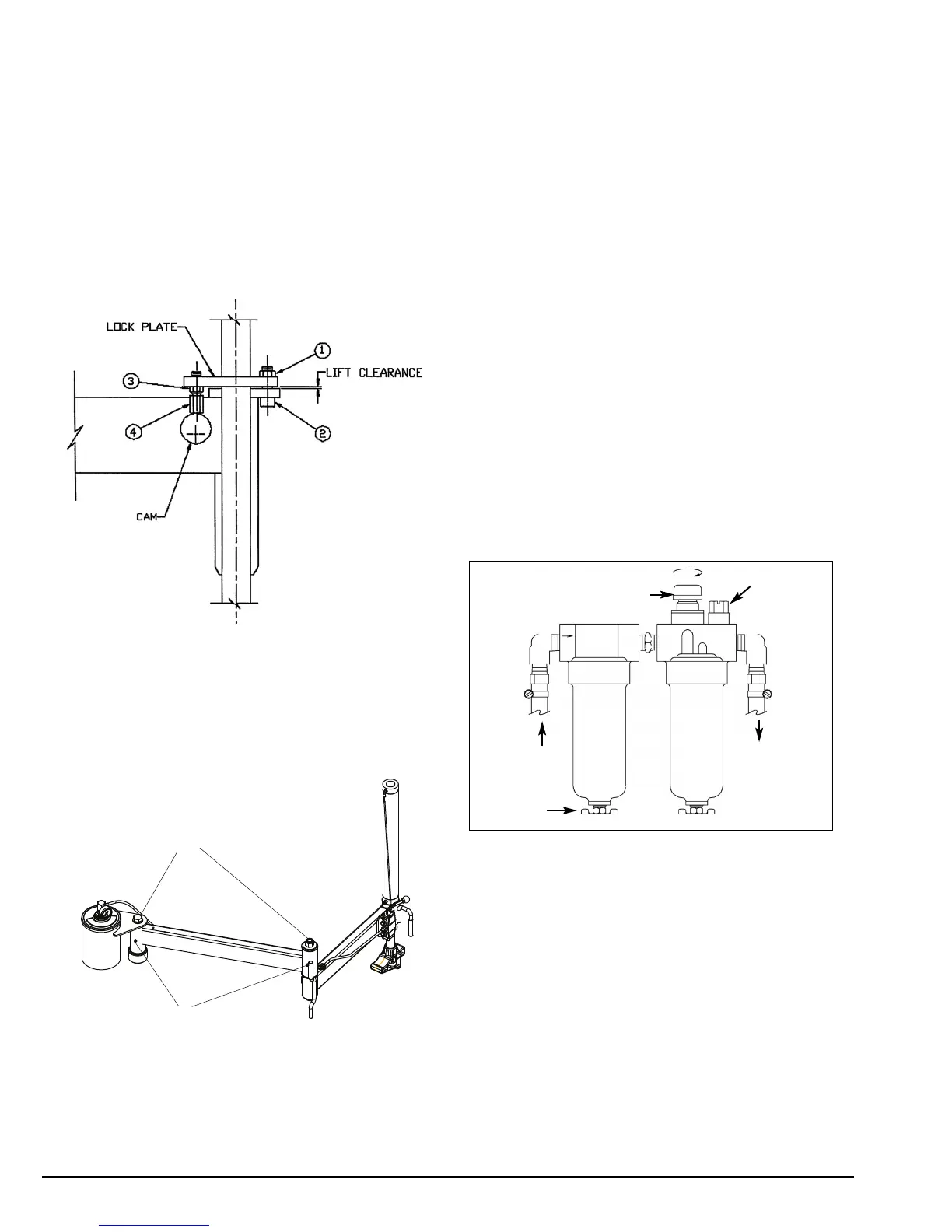

Adjustment

To Adjust Tool Head Lift

Loosen jam nut (ref. 1) and adjust screw (ref. 2) until

lift clearance is obtained.

To Adjust Lock Tightness

With lock handle unlocked, loosen jam nut (ref. 3) and

adjust pin (ref. 4) until a slight firmness is obtained,

then tighten jam nut and check. Also recheck tool head

lift at this time.

Robotic Arm Maintenance

A. Grease the Robo Arm™ to maintain smooth rota-

tion. Grease fittings have been provided at the pivot

joints.

B. Check bolt torque periodically at pivot joints.

Proper torque is 240 ft. lbs.

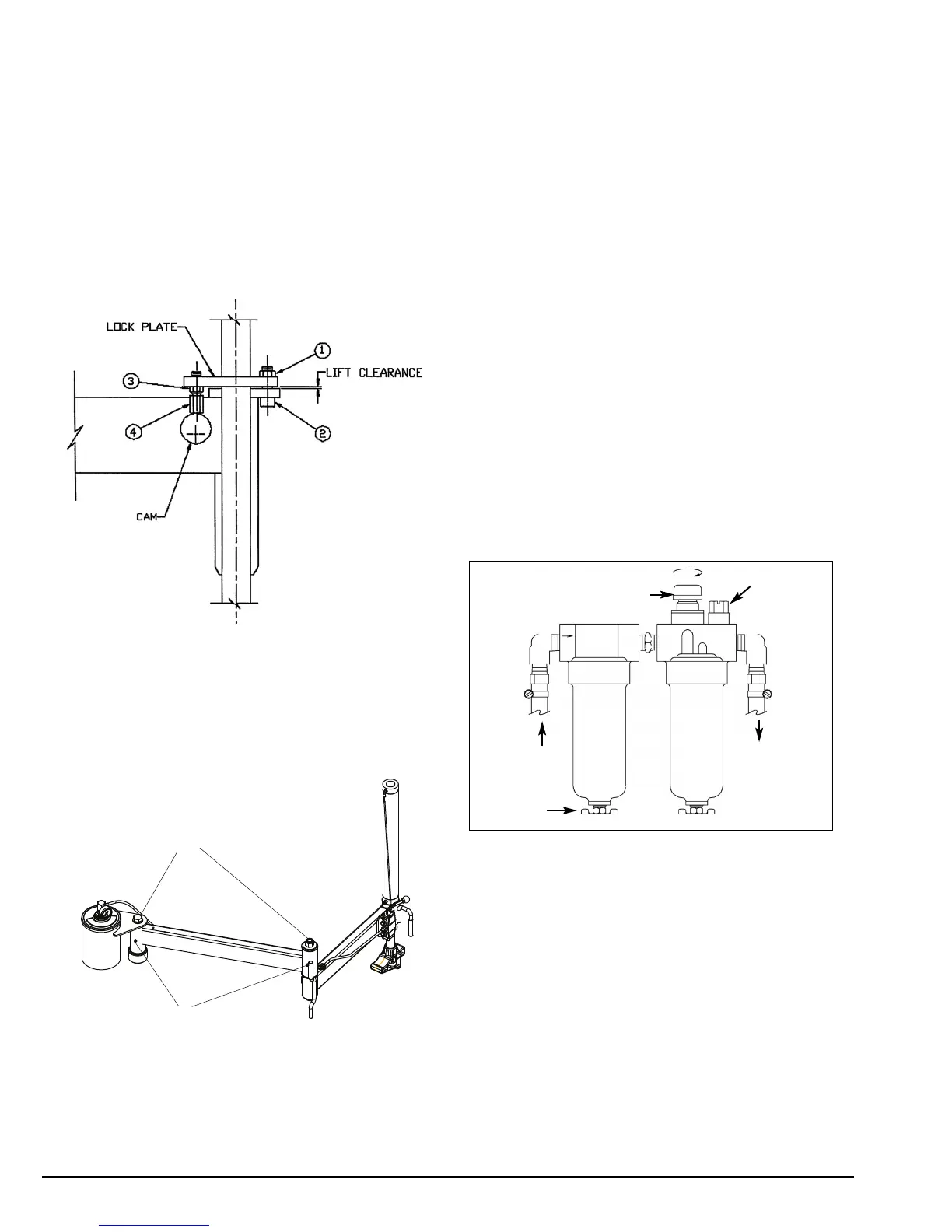

Separator/Lubricator Maintenance (If

equipped)

Check oil and water levels regularly, and perform

these maintenance items weekly:

A. Disconnect air supply to machine.

B. Drain water from the separator by unscrewing the

petcock on the bottom of bowl. Allow water to drain

and tighten petcock securely by hand.

The Separator (Filter) unit is equipped with an auto-

matic drain and should not normally need draining.

C. If the fluid level is more than 1/4" from the top of

the gauge, add oil. Remove the filler plug on top of the

lubricator and add SAE 10W non-detergent oil or an air

tool oil to bring the level up to 1/4" from the top of the

gauge. Replace filler plug and clean up any spilled oil.

D. Adjust the oil flow by turning the black flow adjust-

ment knob and turning it to increase or decrease the

flow. Watch the formation of oil drops in the see-

through oil chamber. Reconnect the air supply and con-

tinually cycle the bead loosener through full strokes

and count the drips during the cycles. The delivery of

oil to the airline should be about 1 drop per 10 cylinder

cycles. Adjust flow as required.

Loading...

Loading...