15

Part 6 Gas Conversion

Gas Conversion Procedure

NOTE:

These conversions should only be carried out by

qualified persons. All connections must be

checked for leaks before re-commissioning the

appliance.

Adjustment of components that have

adjustments / settings sealed (e.g. paint sealed)

can only be adjusted in accordance with the

following instructions and shall be re-sealed

before re-commissioning this appliance.

For all relevant gas specifications refer to the

tables at the end of this section.

Open Burners

1. Remove pot stands,

burner caps, burner

bodies and pot stand

supports.

2. Remove injectors and replace with correct size

injectors as shown in ‘Gas Specifications Tables’

at end of this section.

3. Refit pot stand supports, pot stands, burner caps

and burner bodies.

4. Re-light main burners and check flame size on

simmer (LOW) position.

Low Fire Adjustment

Adjust low fire adjustment screw on open

burner gas control valves to obtain desired

flame size.

NOTE: The 'Low Fire Screw' should be sealed with

coloured paint on completion of low fire

adjustment.

Aeration Adjustment

1. Check / adjust main burner aeration gap. This

gap should be set to the dimensions shown in

the 'Gas Specification Tables' at the end of this

section.

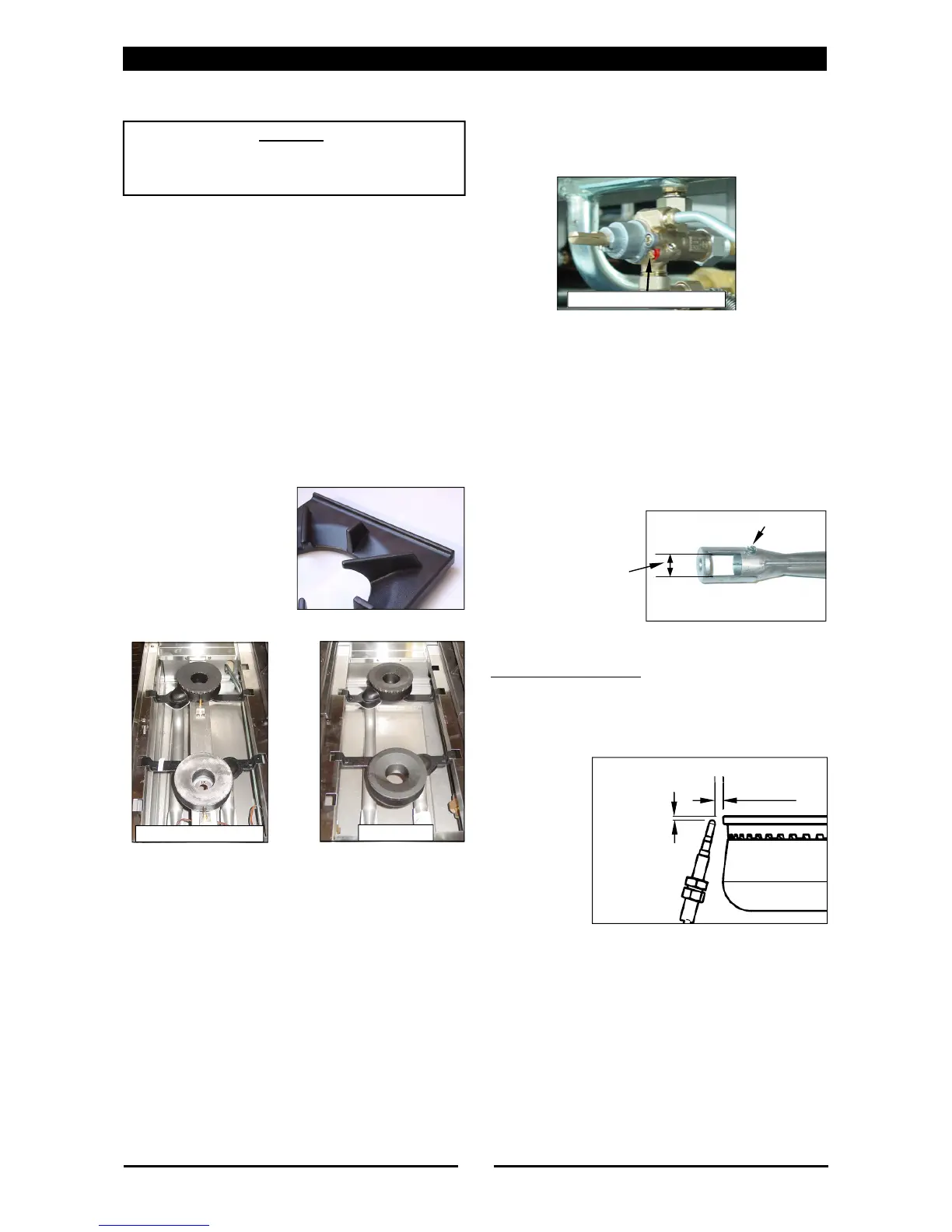

Thermocouple Location

1. Check that thermocouple is correctly located

and that the gap between the thermocouple

and main burner is as shown in the diagram be-

low.

2. Check that the thermocouple to gas valve

connection is tight.

C

AUTION

:

Ensure that the unit is isolated from the gas

supply before commencing servicing.

Std Burners

Flame Failure Burners

Low Fire Adjustment Screw

Refer to 'Gas

Specification Tables'

Adjustment Screw

3 ±1 mm

2 ±1 mm

Loading...

Loading...