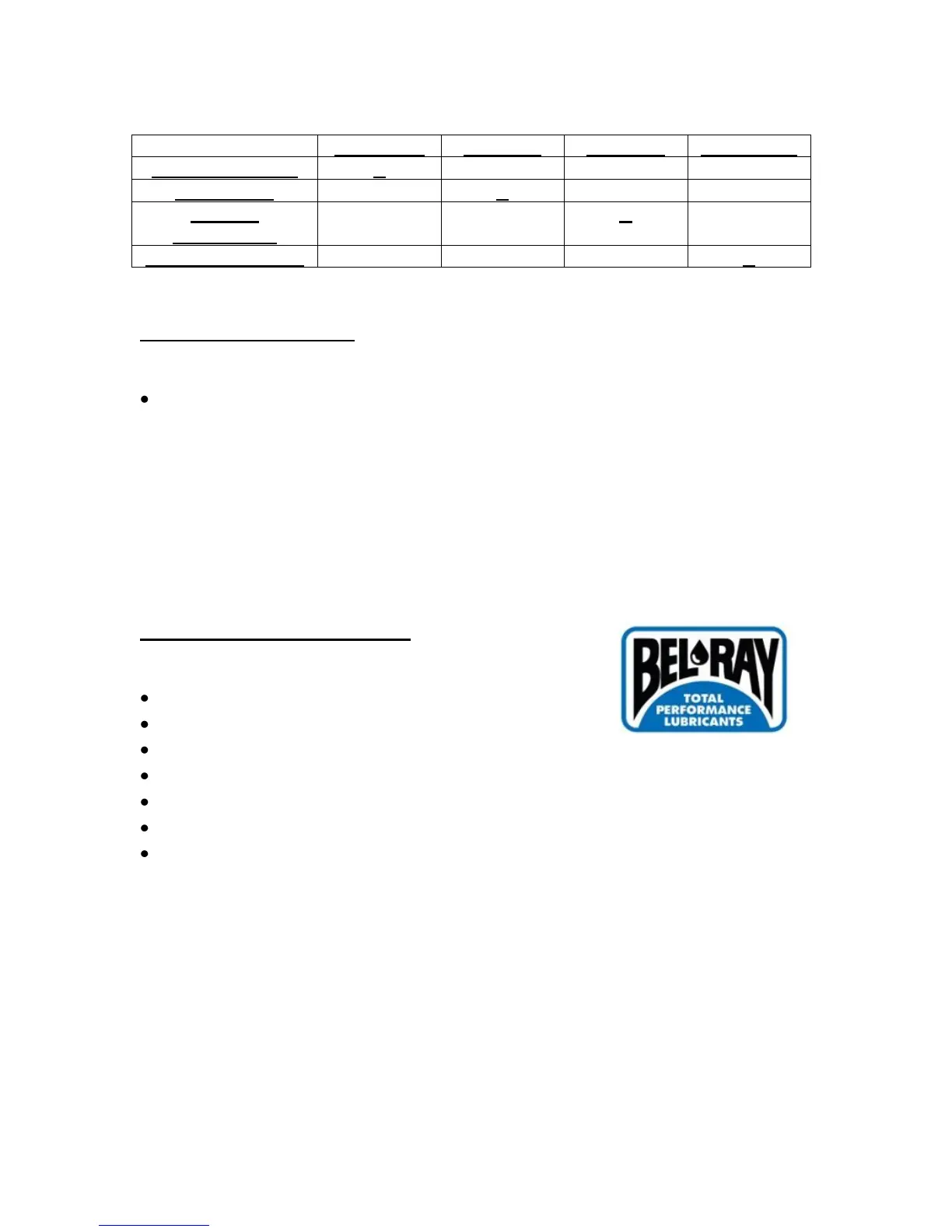

For routine maintenance, the chart below provides suggested service intervals

for common procedures:

Fork Air Bleeding

Tools required

3mm hex key (Allen wrench)

During normal operation, both fork legs will build up air pressure. This pressure

acts as an additional spring so it must be bled on a regular basis to maintain

consistent suspension operation. Before each ride, loosen the socket head cap

screw located at the front of each fork cap far enough so that any excess

pressure in the leg is relieved. After excess air is bled off, retighten the screw to 5

in-lb. Be careful not to lose or damage the sealing ring that is located under the

head of each bleed screw.

Fork Oil Replacement

Tools required

37mm Fork Cap Tool (MCMUTL37)

22mm closed-end wrench or socket

14mm open-end wrench

Drift punch (12mm OD x 300mm long (1/2” x 12”))

5 & 6 mm hex key (Allen wrench)

Mallet

2.5 wt. Bel-Ray fork oil

Disassembly procedure

1. Remove the front wheel.

a. Loosen the brake-side axle pinch bolts (5mm hex key)

b. Carefully remove the brake side axle cap using a closed-end wrench to

protect the cap from damage. (22mm wrench)

c. Loosen the non-brake side axle pinch bolts (5mm hex key)

d. Using the drift punch (a long 3/8 socket extension will also work),

remove the axle from the fork lugs by placing the punch inside the

hollow axle and tapping lightly on the exposed end with the mallet.

Loading...

Loading...