920-0505-00 Rev. B

Page 9 of 12

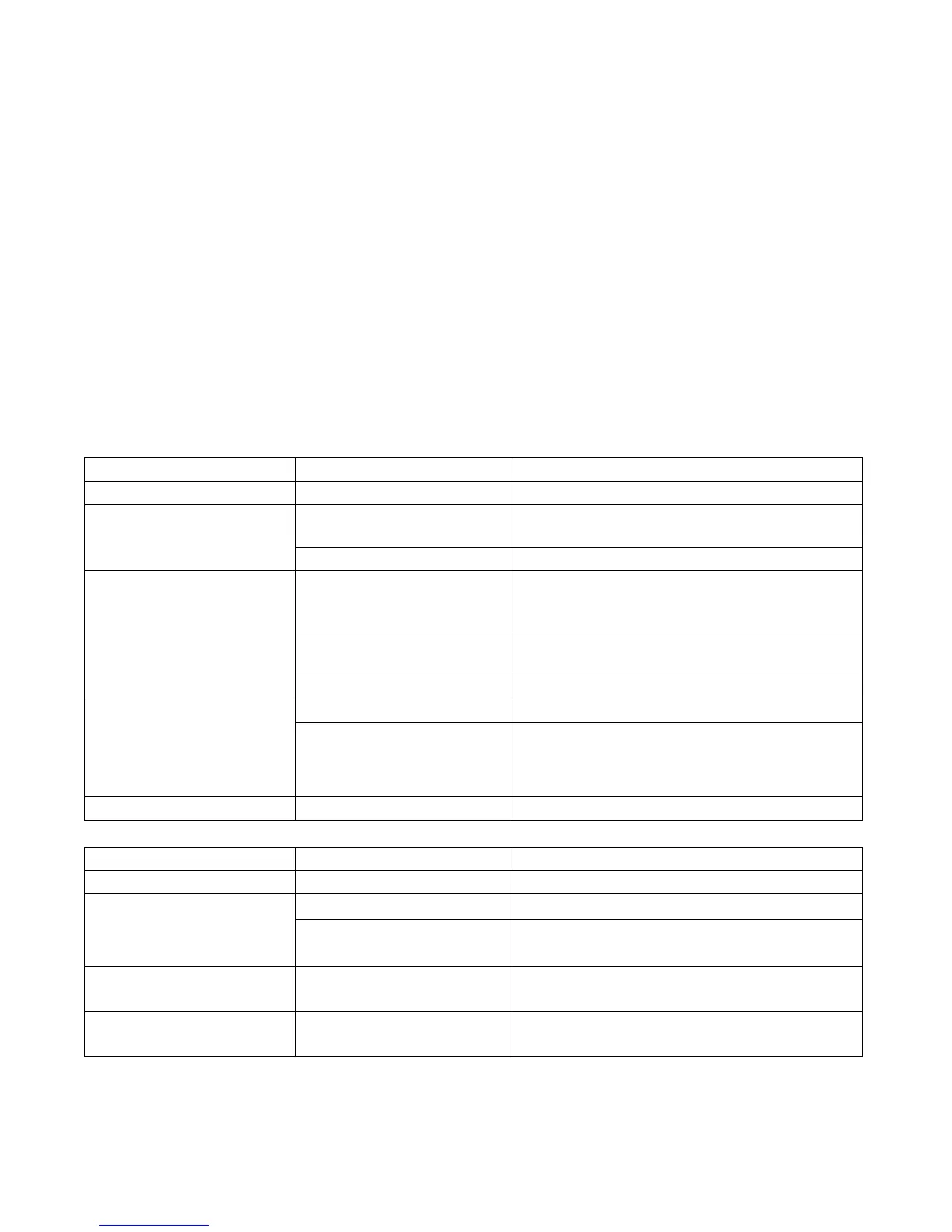

Control Box Issues

PROBLEM POSSIBLE CAUSE SOLUTION

Fuse Blows ¹ Wires short circuit Check power and ground for short circuits

Faulty unit

If fuse continues to blow after checking the

wiring replace the product

Unstable operation Wiring fault Check that wire colors match the label positions

on Junction Box

Output on Junction box is

not working

Junction box fuse blown

(excessive load)

Replace the Junction Box

¹

Note: Always replace the fuse with the same value as removed

Troubleshooting

Maintenance

Occasional cleaning of the lenses will ensure optimum light output. Take care when cleaning lenses, although very

impact resistant, polycarbonate scratches easily. Clean the lens and base with soap and water or a lens polish

using a microber or other lint free soft cloth. Do not use solvents as they may damage the polycarbonate.

Lens Removal and Installation

1. Identify the lens(es) to be removed - not all lenses need to be removed to access the internal components.

2. Unfasten the retaining screws from the lens(es) of the lightbar - the screws can be left captive in the lens.

3. Carefully lift the lens off the seal – choose a suitable location to temporarily store the lens so as to not scratch

the surface.

4. When reinstalling, gently apply pressure around the upper lens taking care not to damage the seal around the

lower lens set. Retorque the retaining screws to 18 IN-LB (2.0 N-M).

All products are thoroughly tested prior to shipment. However, should you encounter a problem during installation

or during the life of the product, follow the guide below for troubleshooting and repair information. If the problem

cannot be rectied using the solutions given below, additional information may be obtained from the manufacturer.

Contact details are at the end of this document.

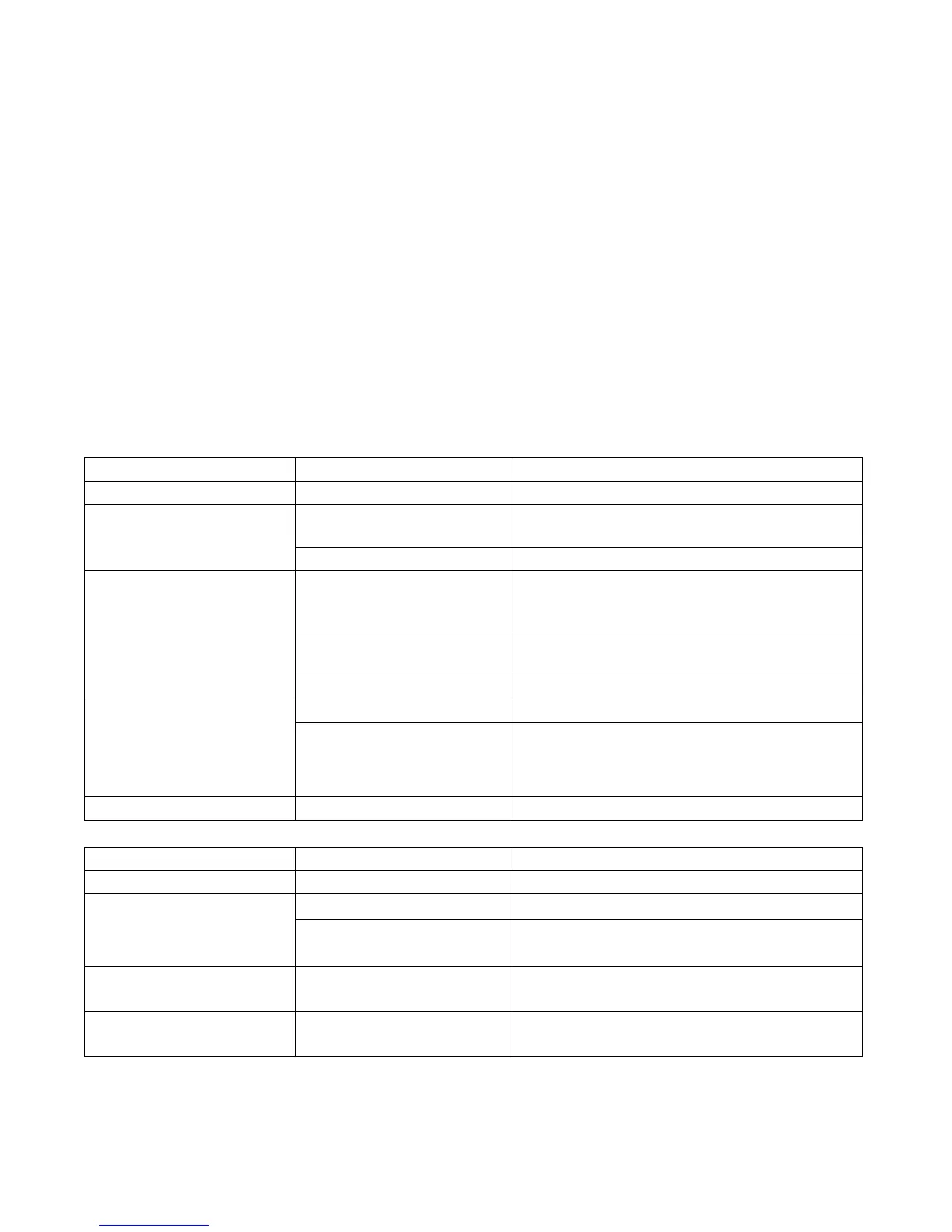

Lightbar Issues

PROBLEM POSSIBLE CAUSE SOLUTION

Lightbar does not function Poor power or ground

connection

Check power and ground connections.

Blown fuse Check wiring, replace fuse

One LED head does not

ash, but corresponding

indicator LED on control

module does ash.

Open circuit wiring from

control module to LED head

Connect a known-good LED head to the

problem output to ensure the control module is

working correctly. Repair or replace.

Poor ground connection at

LED head

Tighten or replace mounting screw.

Failed LED head Replace LED head

One LED head does not

ash, and corresponding

indicator LED on control

module does not ash when

appropriate pattern selected.

Wrong ash conguration Use C3Pro Conguration Programmer to correct

Failed control module Replace control module

Incorrect ash patterns Wrong ash conguration Use C3Pro Conguration Programmer to correct

Loading...

Loading...