OpInstructions_En.fm

4

4 Introduction

Characteristic features of the Collamat 2600-system:

• low wearing, no clutch/brake system

• compact, easy handling due to flying modular design

• easy to operate

The modular concept allows homogeneous fastening of the peripheral de-

vices on one module-bar (position bar with integrated scale). The respective

electronic control is integrated in the device itself.

The communication between each peripheral device happens via the bus-sy-

stem which is placed in the module-bar of this system.

The operating elements for the dispensing speed, predispensing, optical la-

bel scanner as well as the main switch with the optical display are placed di-

rectly on the traction unit case.

All parts are corrosion-resisting and the tractionroller of the traction unit is fur-

nished with a special coating to assure a lasting slip-free transmission of the

torque onto the carrier paper of the label strip. The rewinding power of rewin-

der spindle as well as the brake force of the paper brake can be adjusted on

the traction unit from the outside.

5 Mechanical adjustment of the dispenser

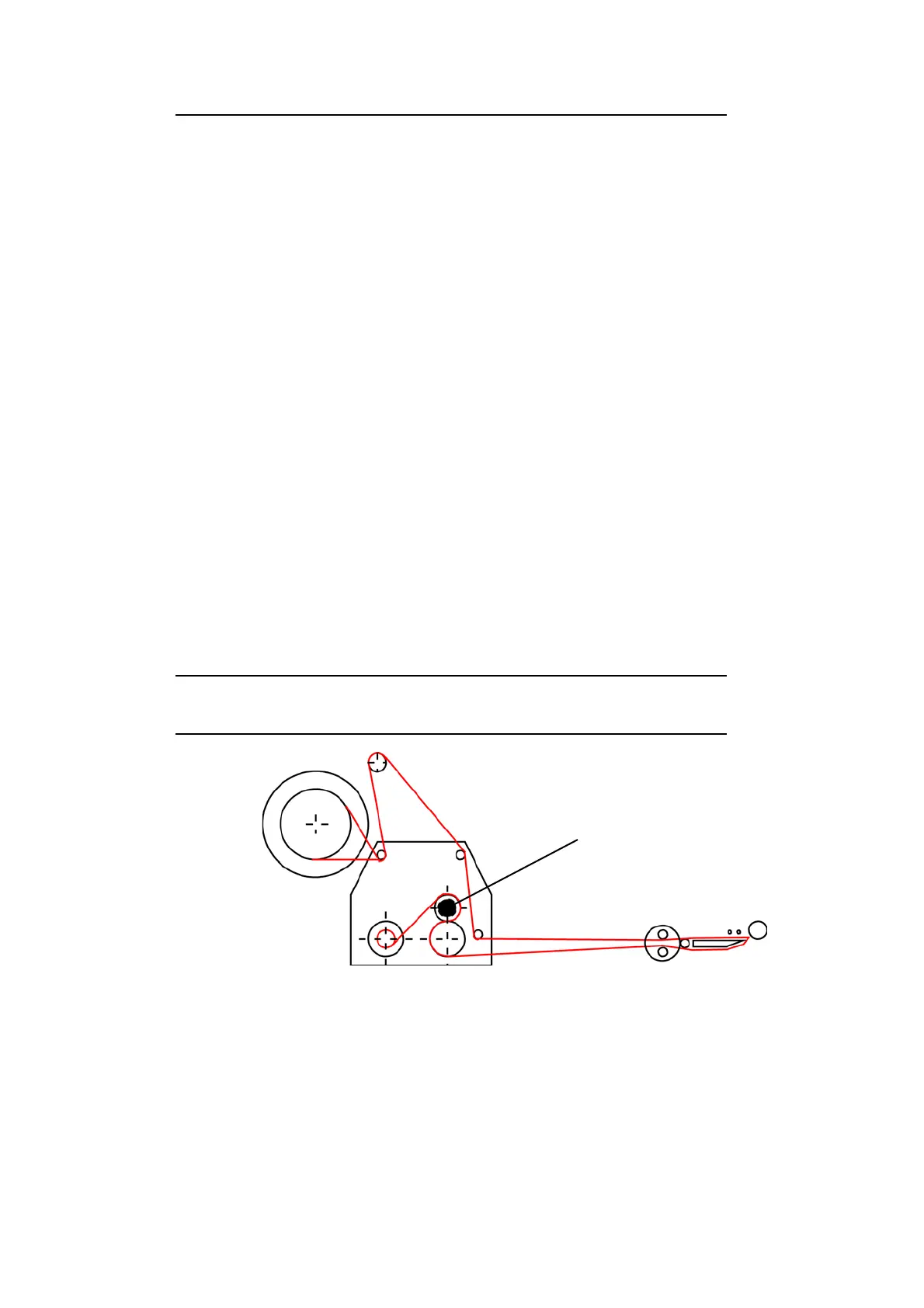

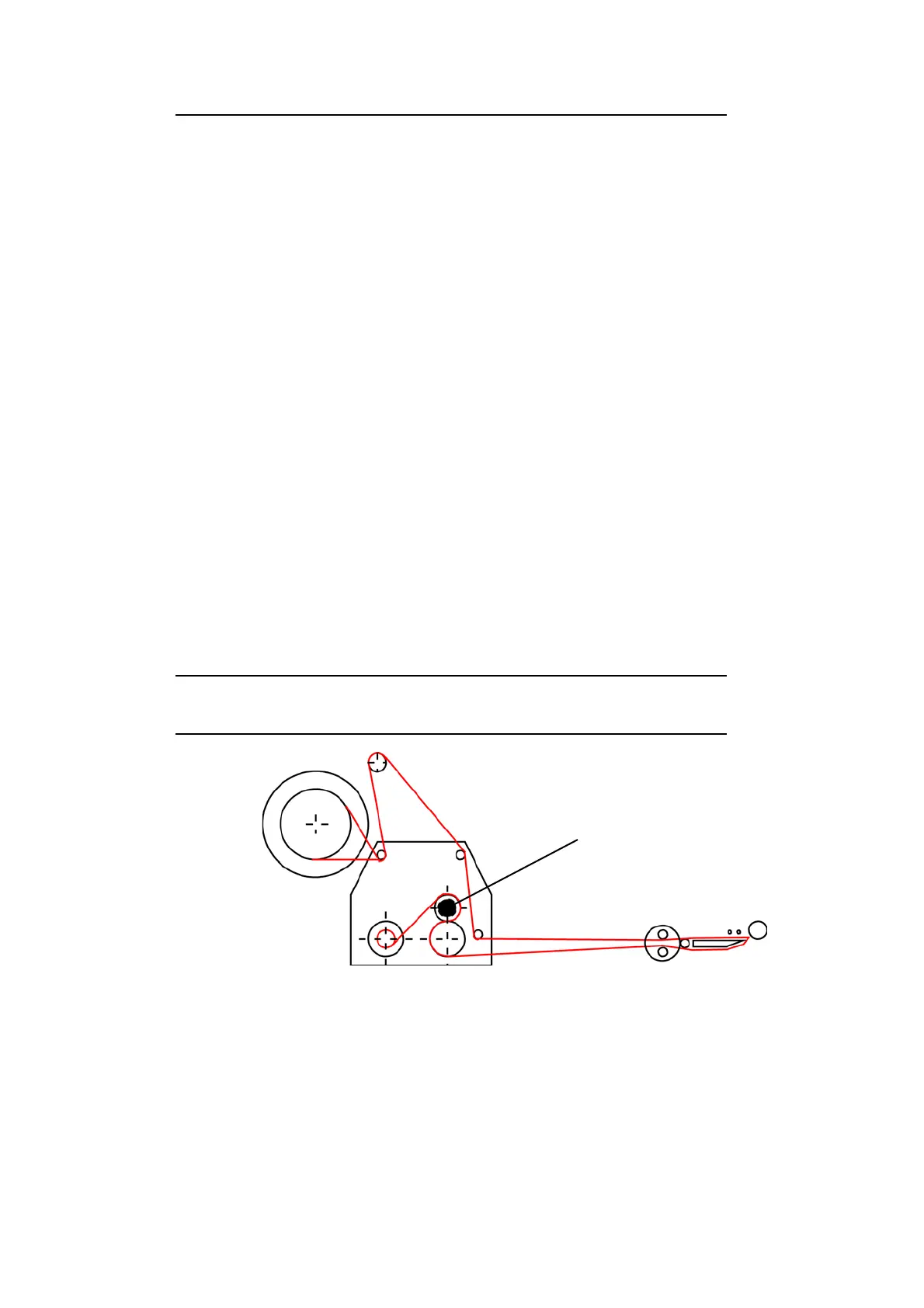

5.1 Threading of the label web

Thread label web according to illustration up to the dispensing edge and pull

forward approx. 1 m.

Detach labels from the carrier strip where it has been pulled forward. Then,

by turning knob (1) open the counter- pressure roller, fold down the carrier

paper (backing paper) over the dispensing edge and finish threading the label

strip according to the illustration above.

Close the counter-pressure roller. Adjust the lateral guides to leave a space

of 0,5 mm between them and the label strip.

1

Loading...

Loading...