17

EN

DECOMMISSIONING

• Re-windthehigh-pressurehose(14)carefully,avoidinganyfolds.

• Re-windthepowercable(4)carefully.

• Storethehigh-pressurecleanerinadryandcleanplace,makingsurenottodamagethepowercable

and the high-pressure hose.

ROUTINE MAINTENANCE

Perform the operations described in the

“STOP”

paragraph, following the chart shown below.

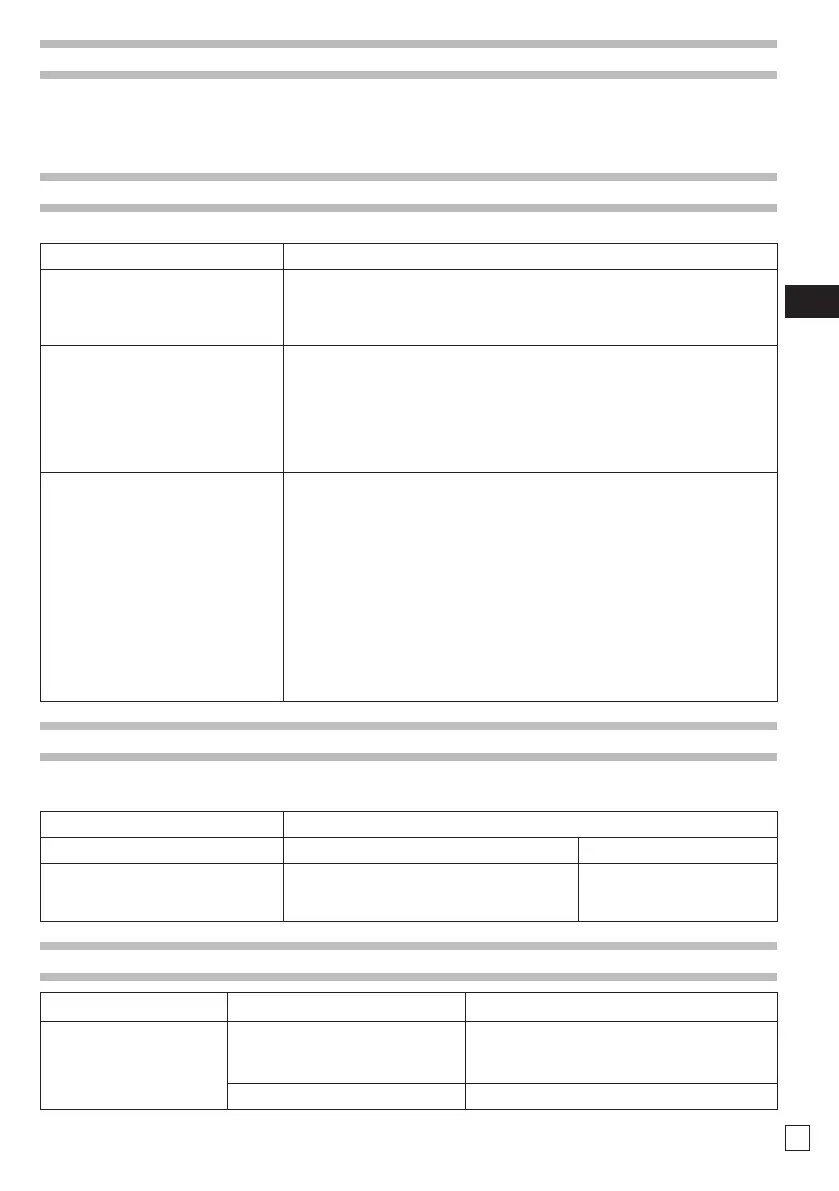

MAINTENANCE SCHEDULE JOB

After every use • Check the power cable, high-pressure hose, connections, spray gun and

lance hose.

If any of these is damaged, do not use the high-pressure cleaner and

contact a

skilled TeChniCian.

Weekly • Cleanthewaterinletlter(21).

Unscrew the quick-fit connection (23) and take out the filter (21).

Generally speaking, to clean this all that need be done is pass the

filter under a jet of running water or blow on it with compressed

air. Inthemostdicultcases,useananti-scaleproductorreplace

the filter. To buy spares contact an authorised after-sales centre.

Fit the lter back on and screw the quick-t connection back on.

Monthly • Cleanthenozzle.

Generally speaking, to clean the nozzle, it is enough to pass the pin (12)

provided through the nozzle hole. If this is not successful, change the

nozzle. Buy this from an authorised after-sales centre. The nozzle can be

changed using a 14 mm wrench (not supplied).

• Cleanthedetergentsuctionlter(16).

Generally speaking, to clean the lter, all you need do is pass it under a jet

ofrunningwaterorblowitwithcompressedair.Inthemostdicultcases,

use an anti-scale product or replace it. Only buy spares from authorised

after-sales centres.

• Checkthepumpoillevel(ETM130).

Use the indicator (5)

(fig. 1). If topping up is required, contact a skilled

T

eChniCian.

SPECIAL MAINTENANCE

Special maintenance jobs must only be performed by a

skilled TeChniCian,

following the table below

(indicative data).

MAINTENANCE SCHEDULE JOB

Every 200 hours • Checkthepump(water)hydrauliccircuit. • Checkthepumpfastening.

Every 500 hours • Pumpoilchange.

• Checkthepumpsuction/deliveryvalves.

• Checkthetightnessofthepumpscrews.

• Checkthepumpregulation

valve.

• Checkthesafetydevices.

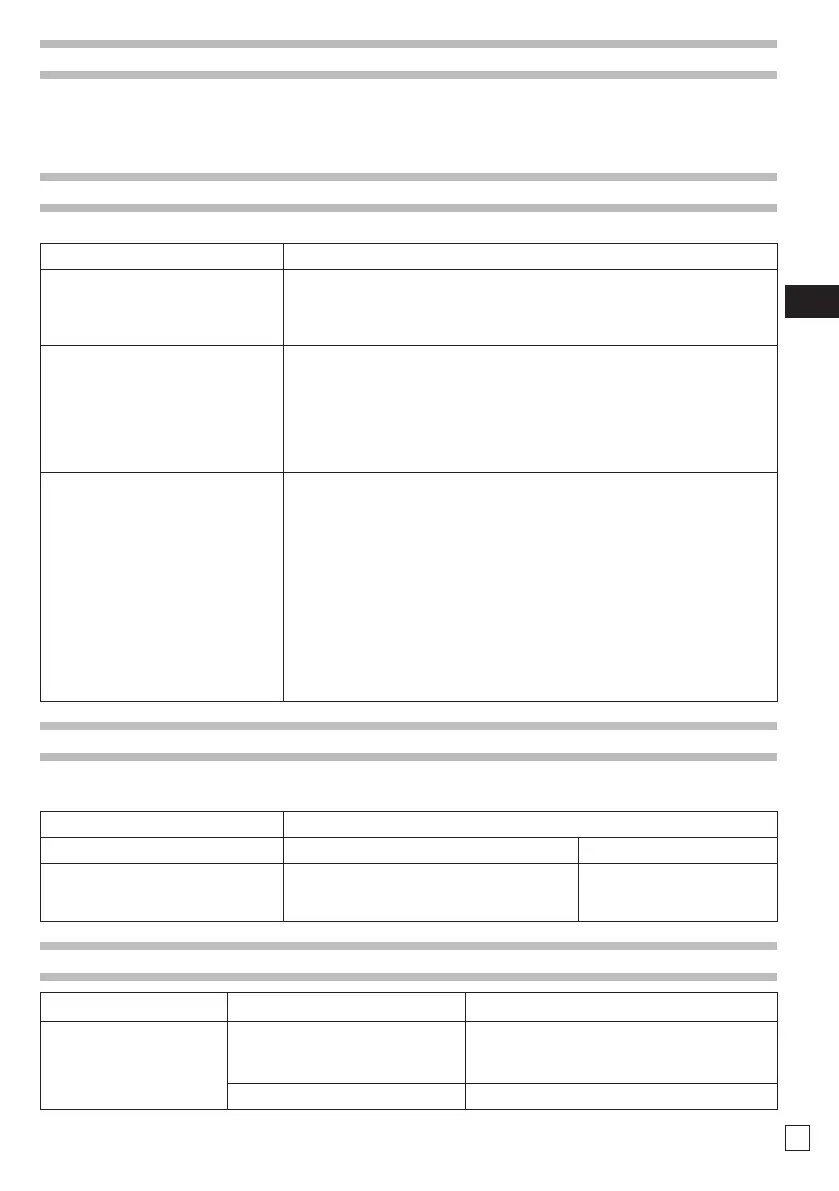

TROUBLESHOOTING

PROBLEMS CAUSES REMEDIES

When the switch (1) is

moved to position “1”, the

high-pressure cleaner does

not start.

Tripping of system cutout device to

which the high-pressure cleaner is

connected (fuse, RCCB, etc.).

Reset the cutout device.

in Case This Trips again, do noT use The high-pressure

Cleaner and ConTaCT a skilled TeChniCian.

The plug is not properly tted. Disconnect the plug and t it back correctly.

(continued on next page)

Loading...

Loading...