27

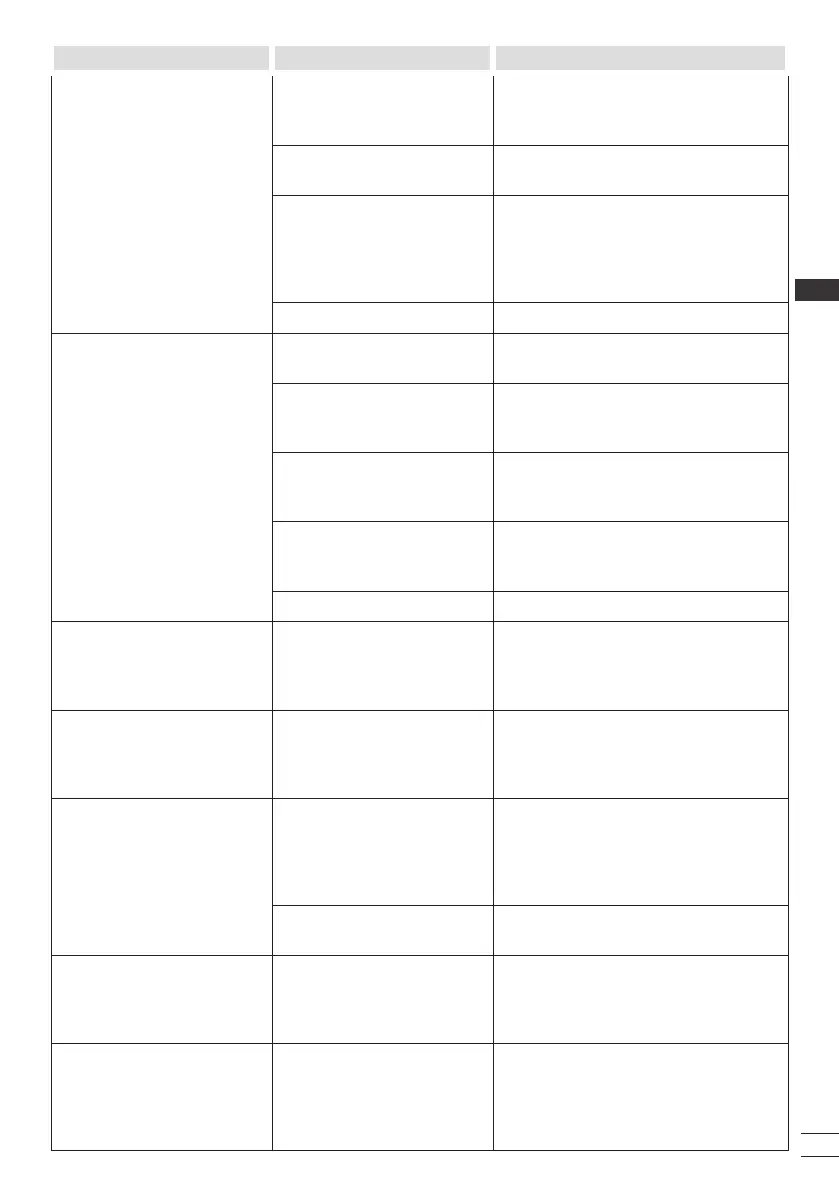

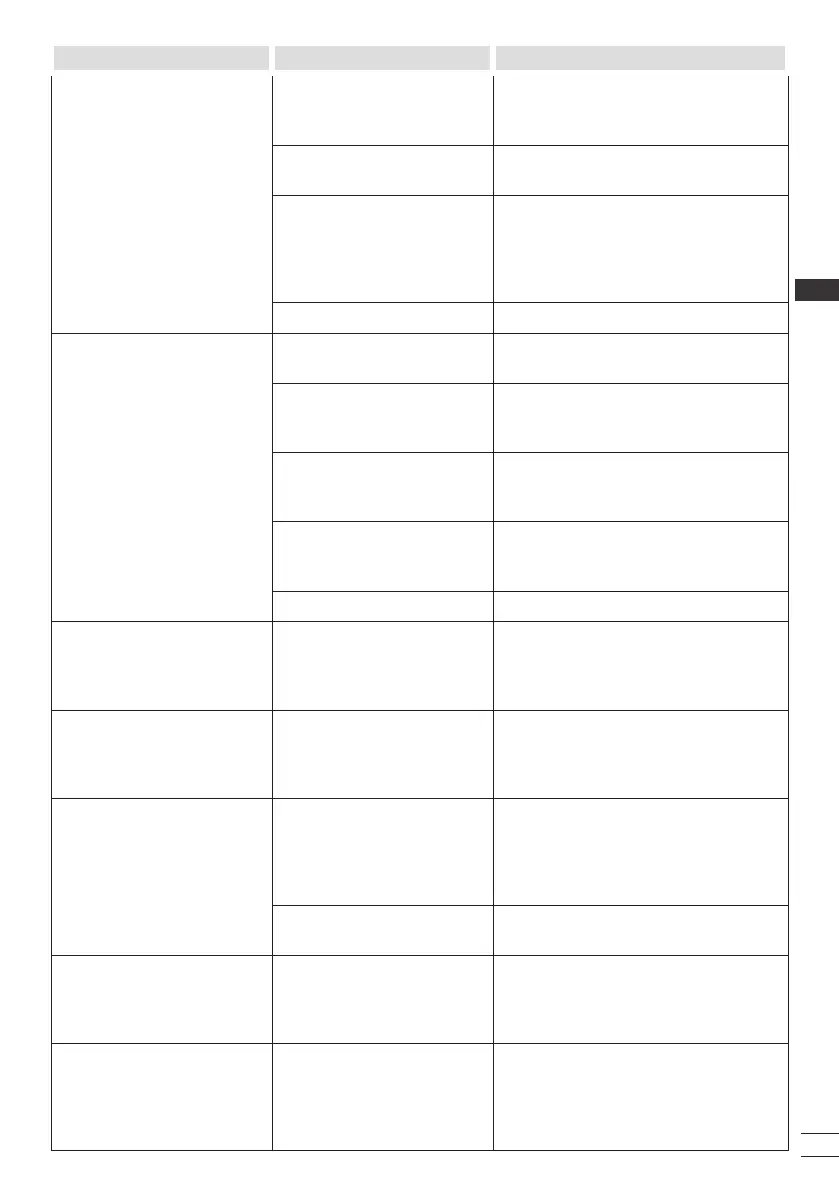

PROBLEMS CAUSES REMEDIES

The high pressure cleaner fails

to reach maximum pressure.

The regulation valve is set

for a pressure lower than the

maximum one.

Turn the pressure adjustment knob (8)

clockwise.

The nozzle is worn. Replace the nozzle as explained in the

“Routine Maintenance”

paragraph.

Not enough water is being

supplied or priming depth is

excessive.

Make sure the tap is fully open and that

the mains flow rate or priming depth

conform to what is specified in the

“Specifications and technical data”

paragraph.

Back-ow preventer fault. Refer to the relative manual.

No water comes out of the

nozzle or ow rate is poor.

No water. Check that the mains water tap is fully

open or the suction pipe can prime.

Priming too deep. Check that the priming depth conforms

to what is specied in the “Specications

and technical data” paragraph.

Water nozzle clogged. Clean and/or replace the nozzle as

explained in the “Routine Maintenance”

paragraph.

Pump priming is incomplete. Follow the instructions given in the

“Operation – Preliminary activities”

paragraph.

Back-ow preventer fault. Refer to the relative manual.

Water leaking from under

the high pressure cleaner

(XTREME).

Thermostatic valve triggered. Reduce the time the high pressure cleaner

stays in the by-pass operating mode

(see also the “Stopping operation”

paragraph).

Water leaking from under

the high pressure cleaner

(XTREME).

Relief valve triggered. IF THIS HAPPENS PERSISTENTLY

DO NOT USE THE HIGH PRESSURE

CLEANER AND CONTACT A

SPECIALIZED TECHNICIAN.

The high pressure cleaner

stops during operation.

Tripping of system cutout

device to which the high

pressure cleaner is connected

(fuse, RCCB, etc.).

Reset the cutout device.

IN CASE THIS TRIPS AGAIN, DO NOT

USE THE HIGH PRESSURE CLEANER

AND CONTACT A SPECIALIZED

TECHNICIAN.

Tripping of thermal protection

or ampere cut-out protection.

Follow the instructions of the “Safety

devices” paragraph.

The high pressure cleaner

starts again spontaneously

from the Total Stop condition

(1001-1251-1501).

Leaking and/or dripping in the

delivery circuit.

Check soundness of the delivery circuit.

When the master switch (1)

is turned notwithstanding the

push button (21) has been

pressed (XTREME), the motor

hums but does not start.

Electrical system and/or

extension are inadequate.

Make sure the power line connection

instructions have been followed (see

the Instruction manual – Safety

precautions), and check the instructions

in the “Installation” paragraph.

EN

Loading...

Loading...