1930 SERVICE MANUAL

SERVICE ADJUSTMENTS (Continued)

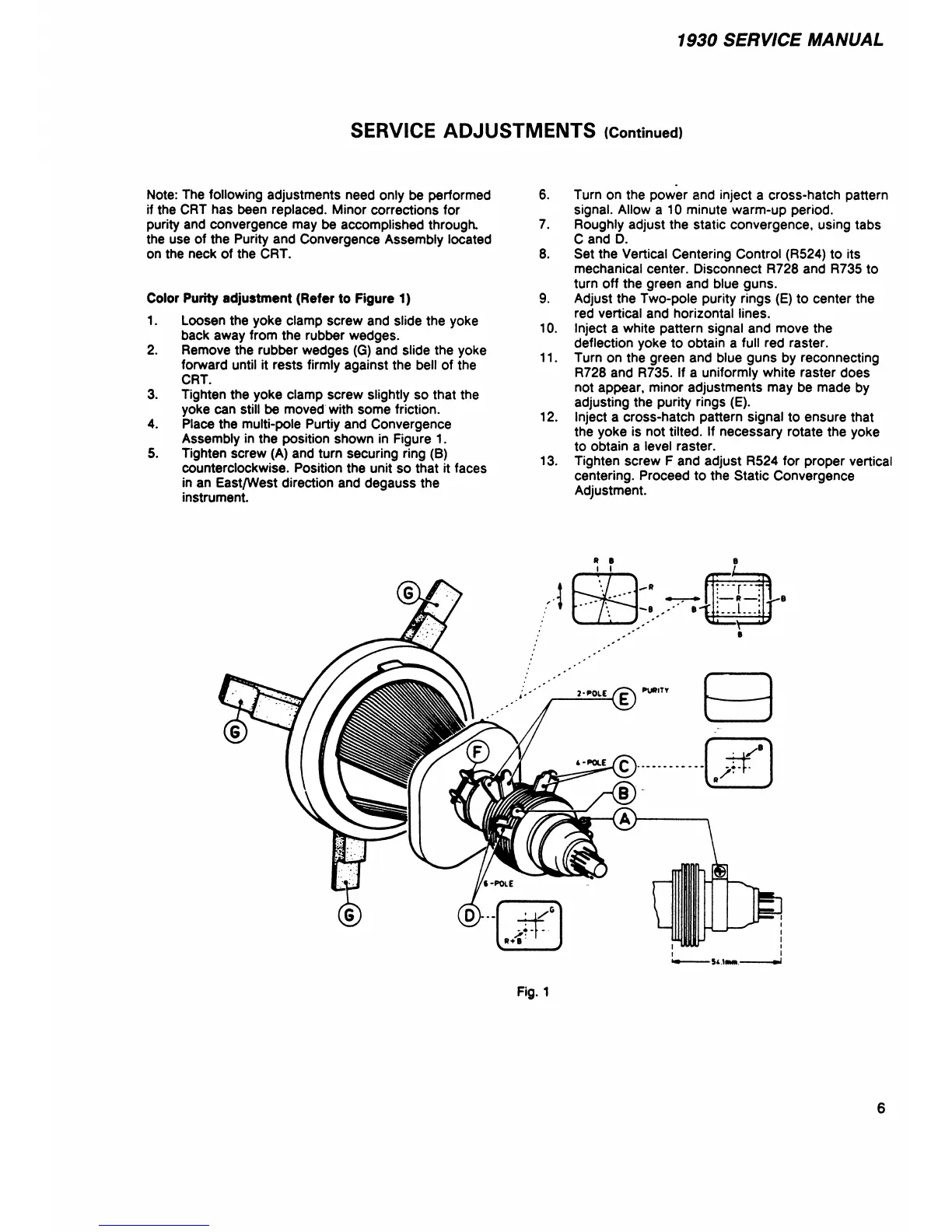

Note: The following adjustments need only be performed

if the CRT has been replaced. Minor corrections for

purity and convergence may be accomplished through,

the use of the Purity and Convergence Assembly located

on the neck of the CRT.

Color Purity adjustment (Refer to Figure 1)

1. Loosen the yoke clamp screw and slide the yoke

back away from the rubber wedges.

2. Remove the rubber wedges (G) and slide the yoke

forward until it rests firmly against the bell of the

CRT.

3. Tighten the yoke clamp screw slightly so that the

yoke can still be moved with some friction.

4. Place the multi-pole Purtiy and Convergence

Assembly in the position shown in Figure 1.

5. Tighten screw (A) and turn securing ring (B)

counterclockwise. Position the unit so that it faces

in an East/West direction and degauss the

instrument.

6. Turn on the power and inject a cross-hatch pattern

signal. Allow a 10 minute warm-up period.

7. Roughly adjust the static convergence, using tabs

C and D.

8. Set the Vertical Centering Control (R524) to its

mechanical center. Disconnect R728 and R735 to

turn off the green and blue guns.

9. Adjust the Two-pole purity rings (E) to center the

red vertical and horizontal lines.

10. Inject a white pattern signal and move the

deflection yoke to obtain a full red raster.

11. Turn on the green and blue guns by reconnecting

R728 and R735. If a uniformly white raster does

not appear, minor adjustments may be made by

adjusting the purity rings (E).

12. Inject a cross-hatch pattern signal to ensure that

the yoke is not tilted. If necessary rotate the yoke

to obtain a level raster.

13. Tighten screw F and adjust R524 for proper vertical

centering. Proceed to the Static Convergence

Adjustment.

* B

i i

Fig. 1

6

Loading...

Loading...