23

COMMON S.A. CGT-OM-18 february.2018

V. PACKAGING, TRANSPORT AND STORAGE

CGT-02 gas meters are supplied in factory-made packaging which provide appropriate

protection during transport and storage. For gas meter sizes from DN50 to DN100,

the packaging consists of reinforced cardboard box and profiled cardboard inserts. Side walls

of the box feature handle holes for transporting the gas meter. Gas meters sized DN150

and larger are placed on appropriate wooden pallets and protected by profiled inserts

and cardboard covers. Appropriate information regarding the contents and restrictions on gas

meter loading/unloading and transport is printed on the packaging.

Gas meters submitted for repair or renewal of legal verification should be sent in factory-

made packaging or other packaging providing at least equal protection during transport.

Each turbine gas meter by Common S.A. is supplied with the following:

- a 6-pin Tuchel C091 31H006 100 2 plug to be used for connecting a volume

converter or recorder to the low frequency electric signal output (in case

the converter has not been connected to the gas meter in the factory);

- a 4-pin Tuchel C091 31D004 100 2 socket, if the gas meter is equipped with a HF

emitter installed in the main body;

- a bottle of oil for the gas meter lubrication system (0.25 L);

- the technical manual.

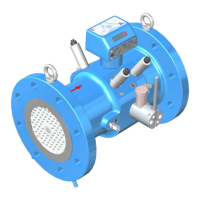

The turbine gas meter is a high precision measurement device

and should be handled with appropriate caution.

Following principles should be observed during transport and storage of the gas meters:

1. Gas meters should not be thrown, turned over or subjected to strong impacts (e.g. during

fast transport using carts without springs).

2. Due to the possibility of oil leaks, the gas meters should be transported only in the target

operation position, i.e. with the oil container cap pointing upward. Position changes

required by the installation process should last as short as possible (maximum a dozen

or so seconds). The above does not apply to gas meters of size DN50 (unless equipped

with lubrication system with piston pump).

3. One must not lift the gas meter by holding the index head. Transport of heavy gas meters

should be performed with the use of lifting eye bolts located in the gas meter flanges.

4. Special care should be taken when loading, unloading and handling high pressure gas

meters, as they are characterized by large weights.

5. Factory-placed covers or other shields on gas meter orifices should not be removed until

directly before installation.

6. The storage site should protect the gas meter from atmospheric precipitation and moisture.

7. Care should be taken of the seals placed on the gas meter. Damage of seals may render

warranty void and legal consequences as regards the clearance of accounts between

the gas supplier and the customer.

8. It is not necessary to lubricate the bearings of gas meters when stored in the warehouse.

Loading...

Loading...