37

COMMON S.A. CGT-OM-18 february.2018

Dust and other impurities may be removed from the gas meter surface using a cloth soaked

in soap and water. Do not clean with solvents or other chemicals.

In case of any incorrectness in gas meter operation (e.g. irregular counter work or counter

stoppage, elevated noise, crackling, oil leaks), the gas meter should be immediately submitted

to repair.

Gas meter repairs may be performed only by the manufacturer or a company

authorized by the manufacturer. Users must not attempt to repair

the gas meters themselves!

Repairs involving the necessity of removing the primary validation seals require renewed

legal approval of the gas meter.

CGT-02 gas meters are subject to manufacturer's warranty. The warranty proceedings

are in line with the general trade law regulations.

VIII. ADDITIONAL EQUIPMENT

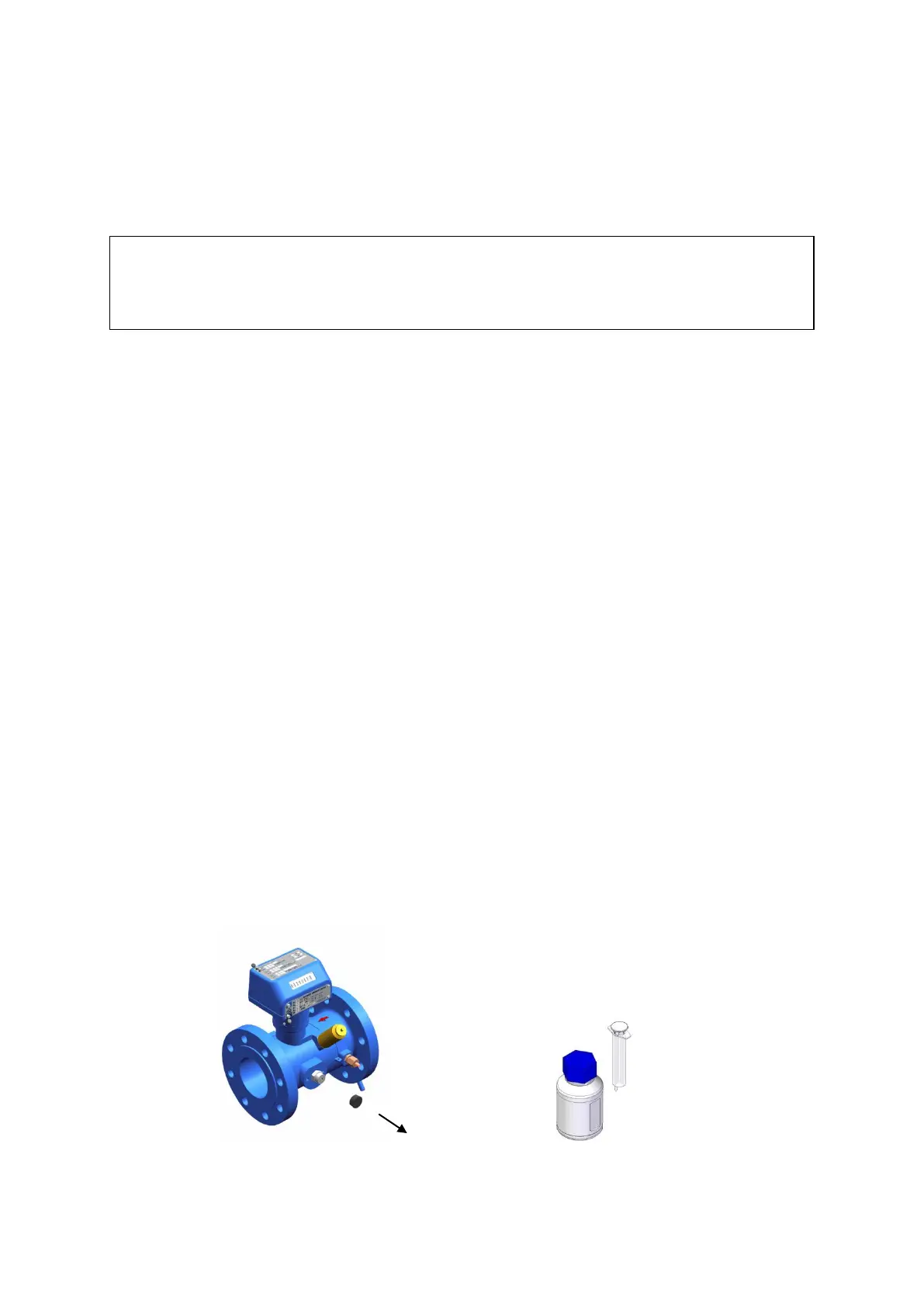

Lubrication kit for lubricating gas meters equipped with lubrication check valve

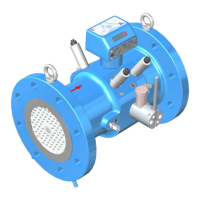

Gas meters CGT-02 series operating in HV positions can be adapted to external lubrication

by means of syringes. These meters are equipped with a system of ducts to transport

lubricating oil to the bearings and a special check valve. Application of oil should

be performed by means of a lubrication kit supplied with a meter. The kit consists of a bottle

with oil and a disposable syringe. It is intended to use when operating pressure does not

exceed 0.5 MPa.

Lubrication procedure is shown below (Fig. 20) and involves:

a. removing a valve cover,

b. preparation of the lubrication kit,

c. drawing proper amount of oil (table 7) into a syringe,

d. inserting the tip of the syringe into a valve slot,

e. pressing (slowly) the oil into the gas meter (lubrication system),

f. pulling the syringe tip out from the valve slot and putting on the valve cover back.

a) b)

Loading...

Loading...