10

D2 – with lever, p

max

≤ 6.3 [MPa], DN200, DN250, DN300, DN400,

D3 – with lever, 6.3 [ MPa] < p

max

≤ 11 [MPa], DN200, DN250, DN300, DN400.

Typical DN50 gas meters are not adapted for external lubrication. These meters can be

optionally equipped with piston pump or lubrication valve.

A sticker is attached to the oil container cover, providing information about the type

of the pump used and the type of oil which should be used. Information about the type of oil

is also provided on the lubrication valve cover.

III. READOUT DEVICE AND MEASUREMENT OUTPUTS

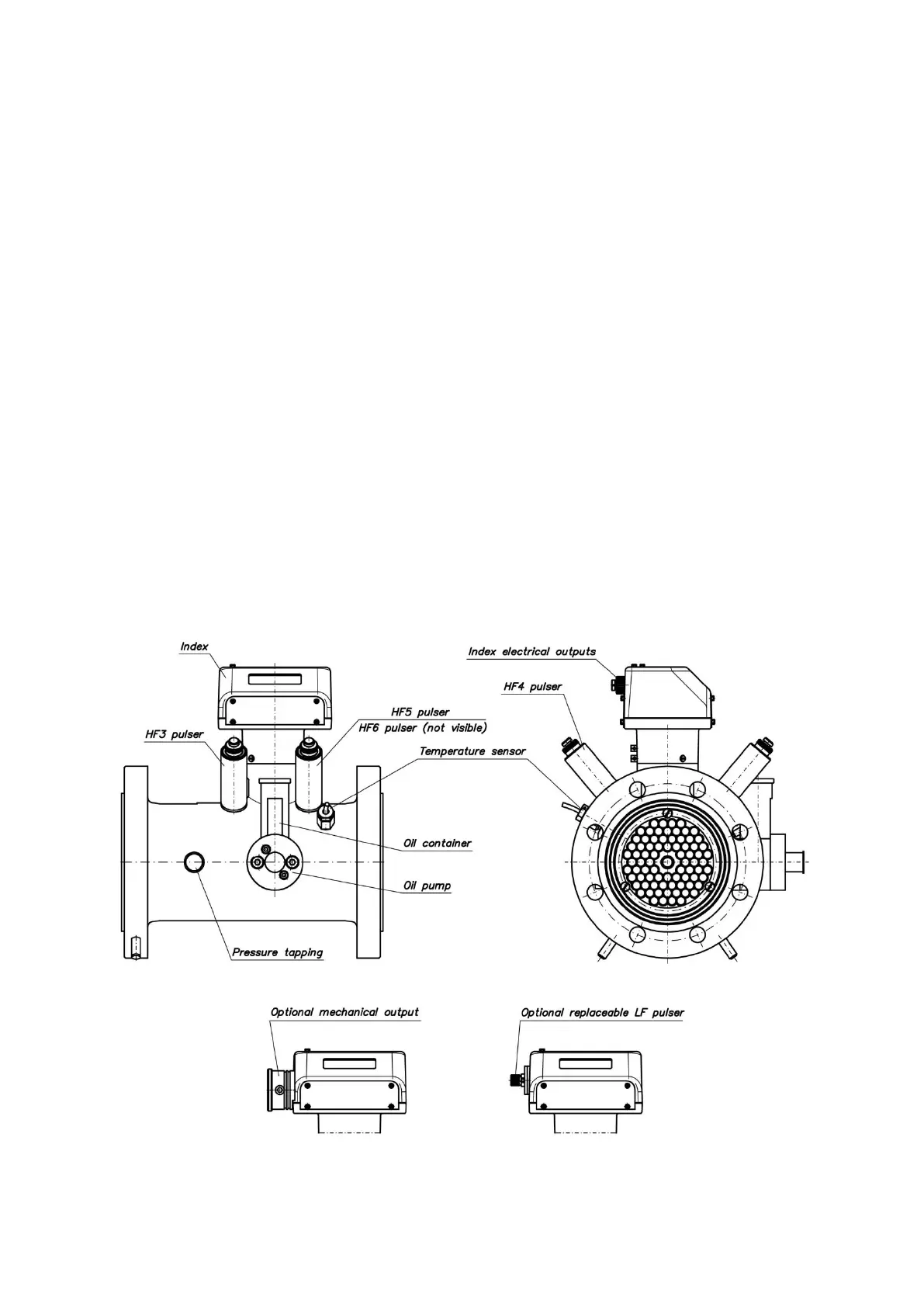

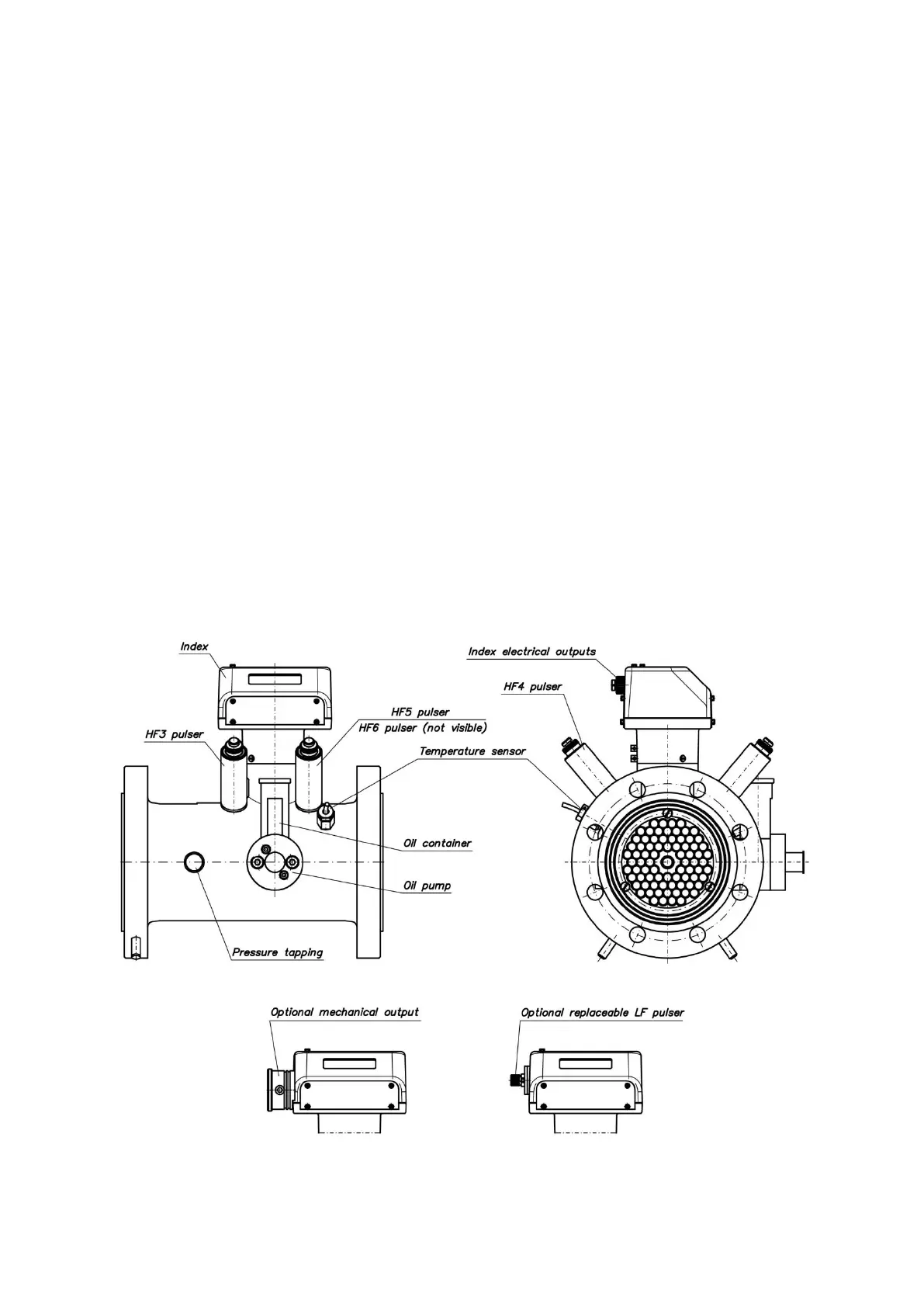

The gas meter CGT-02 is equipped with a readout device in the form of a mechanical

counter with electric signal outputs. The body of the gas meter is equipped with sockets

for implementation of external HF emitters and sockets for the (optional) measurement

of pressure and temperature. Such measurements enable monitoring the gas meter operation

and connecting to the external equipment. Fig. 3 shows the location of the measurement

outputs of the gas meter.

The mechanical counter is located inside the index head assembly and visible through

a polycarbonate inspection window. The counter allows direct readout of the actual volume

of gas that has flown through the gas meter under particular pressure and temperature

conditions. The index assembly may be rotated around its axis in a range of ca. 350

o

, allowing

for convenient readout of the counter from virtually all directions.

Fig. 3. Location of measurement outputs of CGT-02 gas meters.

Loading...

Loading...