9

COMMON S.A. CGT-OM-18 february.2018

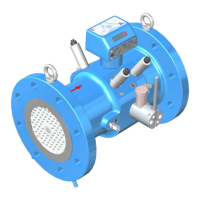

The turbine gas meter CGT-02 (Fig. 2) is built of the following units:

Main body. The main body carries all loads coming from both the gas pressure

and the installation stresses in the pipeline. Bodies of the gas meters with nominal diameters

of DN50 up to DN200 and PN16 or PN20 pressure flange ratings may be manufactured

in two versions – either machined steel forgings or ductile iron castings. Bodies of PN25,

PN40, PN50, PN63, PN100 and PN110 ratings are available only as steel versions. Bodies of

nominal diameters DN250 and larger are always made of welded steel. Each body

is equipped with two connection flanges with type “B” faces and connection dimensions

compliant with the EN 1092-1:2007+A1:2013 and the ISO 7005-1:1992 standards. The

flange dimensions, as well as overall dimensions and estimated weights of the gas meters in

standard versions are listed in Tables 3a and 3b and indicated in Figure 18. On special orders,

the body may be delivered with different types of flange facings compliant with European ,

ANSI or GOST standards. Gas meters bodies are fitted with connectors for high frequency

signal emitters, sockets for pressure gauges and sockets for thermowells (see section III).

Measurement turbine assembly. The measurement turbine assembly consists of the turbine,

the gear system and the inlet straightener. The turbine rotor is placed along the gas meter body

axis and seated on two high precision ball bearings. The flow straightener placed in front

of the turbine makes the gas flow symmetrical and directs it onto the turbine blades. The gear

system (consisting of a worm gear and a spur gears) reduces and transfers the rotational speed

and transmits the drive onto the magnetic coupling.

Drive transmission assembly. The drive transmission assembly consists of a magnetic

coupling with gas-tight partition. The driving part of the coupling is located inside

the partitioned chamber, while the driven part is located outside the partitioned chamber.

The coupling transmits the drive from the pressure zone to the counter assembly, located

outside the gas flow area. The driven part of the coupling may be equipped with a reference

wheel acting as an inducer for the high frequency emitter.

The index assembly. The index assembly reduces the rotational speed further (by means

of a worm gear and spur gears) to drive the mechanical counter and the parts that induce

the low frequency electric signal emitters. The assembly is also fitted with sockets (electrical

outputs) for transmitting the low and high frequency electric signals outside the gas meter.

The gas meter counter can be optionally equipped with a mechanical output. Optionally the

CWSL Encoder can be connected to the optional mechanical output. There are 3 versions of

(optional) Encoders available: CWSL-N, CWSL-A, CWSL-M. Data sent from CWSL-N are

equal to data on the index.

Lubrication system. The lubrication system is used to lubricate the turbine rotor bearings.

The other mechanisms of CGT-02 gas meters are not subject to external lubrication

and make use of bearings equipped with grease reserves. The greasing of the rotor bearings

may be executed by means of a manual piston pump with integrated oil container or via

a lubrication kit.

The CGT-02 series gas meters are offered in the following versions:

maintenance-free (without external lubrication, with spare quantity of grease in bearings);

with special valve for periodic external lubrication (with a lubrication kit);

with piston pump for external lubrication.

The CGT-02 series gas meters can be equipped with piston pumps of the following four

types:

P1 – with pushbutton, p

max

≤ 2 [MPa], DN50, DN80, DN100, DN150,

D1 – with lever, 2 [ MPa] < p

max

≤ 11 [MPa], DN50, DN80, DN100, DN150,

Loading...

Loading...