36

VII. OPERATION MONITORING, MAINTENANCE, FAILURES, REPAIRS

In any doubt regarding the correctness of gas meter readings, the gas meter should be

removed from the system and submitted to an appropriate laboratory verification

of its metrological characteristics. The test may be performed using the control element,

without removing the legal verification seal. One of the HF emitters installed in the gas meter

body may act as a control element. If no HF emitter has been installed in the gas meter, either

a CHFI-01 or a CHFI-03 HF emitter should be connected to act as a control element.

The external control element may be installed in either of the HF3 and HF4 main body

sockets (Fig. 3), after the protection seal and the plug have been removed. The control

element (HF emitter) should be screwed in at a depth allowing for a proper (i.e. consistent

with the Namur standard) emitter signal to be obtained. After completion of the test

and removal of the control element, the socket should be tightly closed using the plug.

A protection seal should be placed on the plug.

CGT-02 gas meters are equipped with a turbine bearings lubrication system (does not apply

to the standard version of DN50 gas meters). The only activity required as part

of the maintenance is periodic lubrication of bearings. Lubrication is carried out by pumping

a proper amount of oil (Table 7) from the oil container into the turbine assembly by pressing

the pushbutton at the front panel of the piston pump type P1 (under the oil pump cover)

or pulling the piston lever in case of pumps D1, D2 or D3. The strength required

for the plunger stroke is lower than 100N. At each lubrication, the level of oil in the container

should be inspected. The oil should be visible through the transparent part of the oil container.

Gas meters designed for p

max

= 0.5 MPa may be equipped with a special lubrication valve

instead of the oil pump. In that case lubrication is achieved by injecting an appropriate dose

of oil through the lubrication valve from a syringe included in the set. Table 7 lists

the recommended oil doses.

For gases listed in Table 1, lubrication should be performed after each gas portion V [m

3

]

as given in Table 7, but not less frequently than once a month. For refinery gases, sewage

gases and sludge digestion gases, lubrication should be performed once every week.

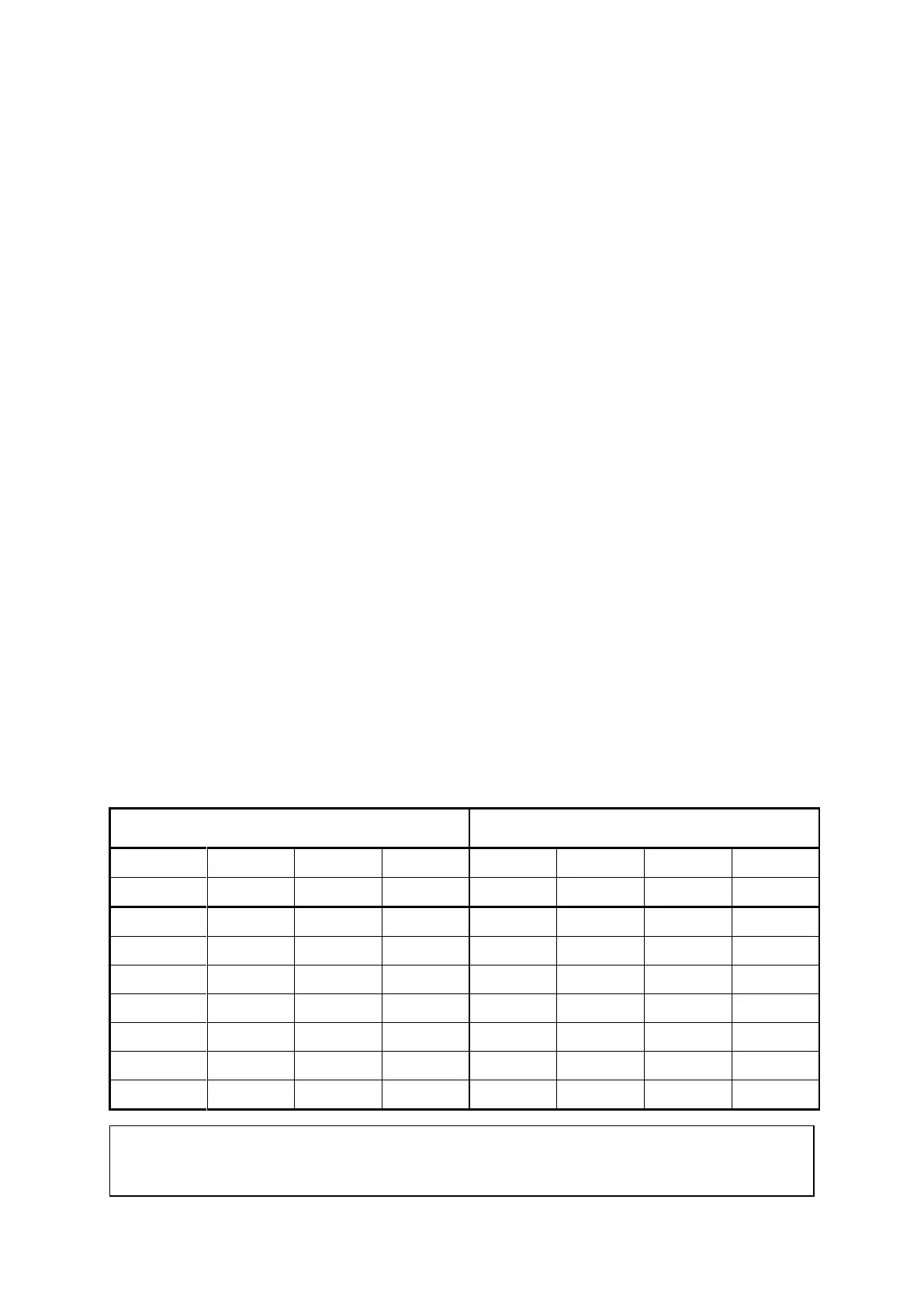

Table 7. Recommended numbers of strokes (n) and oil volumes (V

oil

)

Information on the type of oil to be used is presented on the lid of the oil container

or on the stopper of the lubrication valve.

Loading...

Loading...