35

COMMON S.A. CGT-OM-18 february.2018

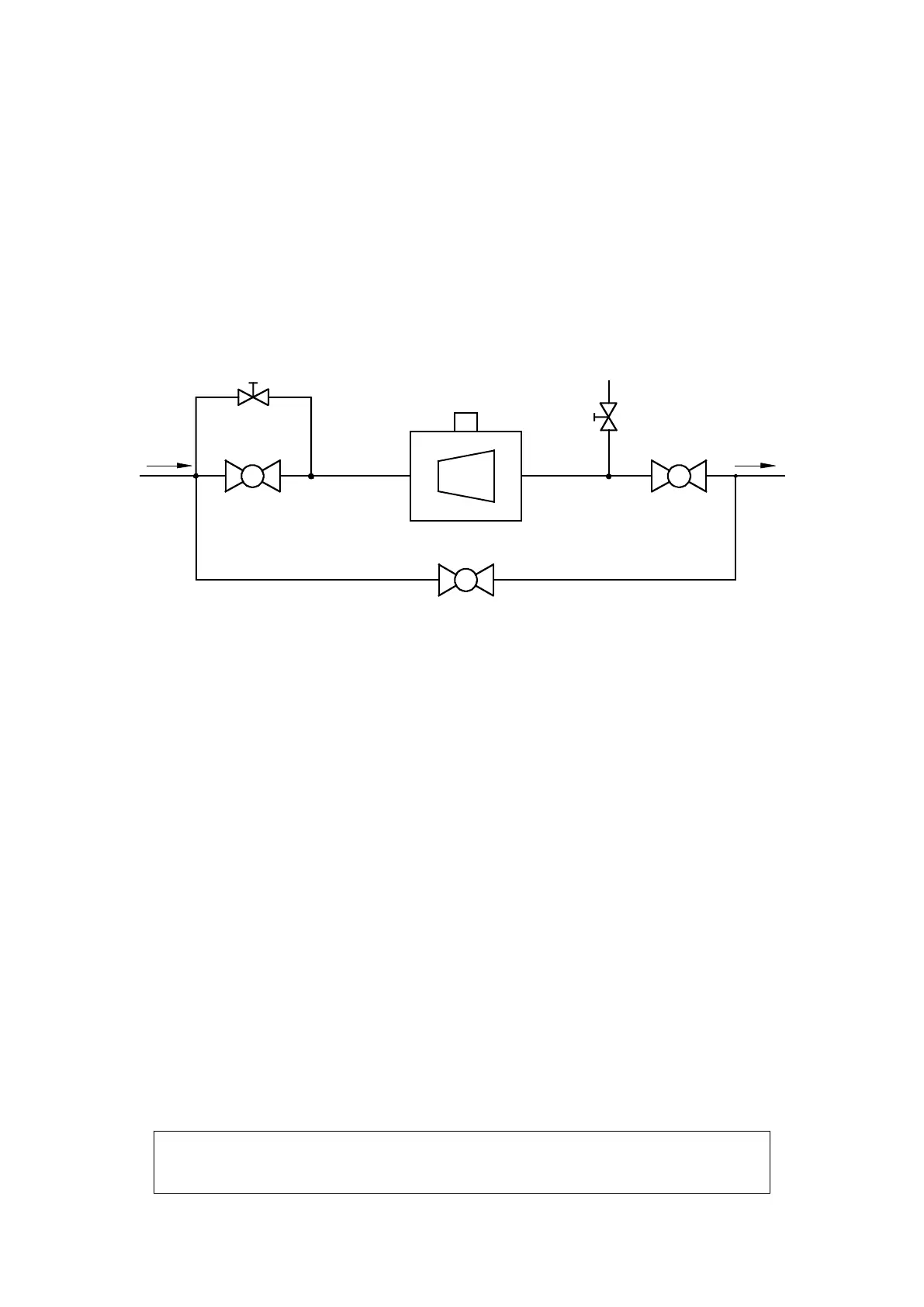

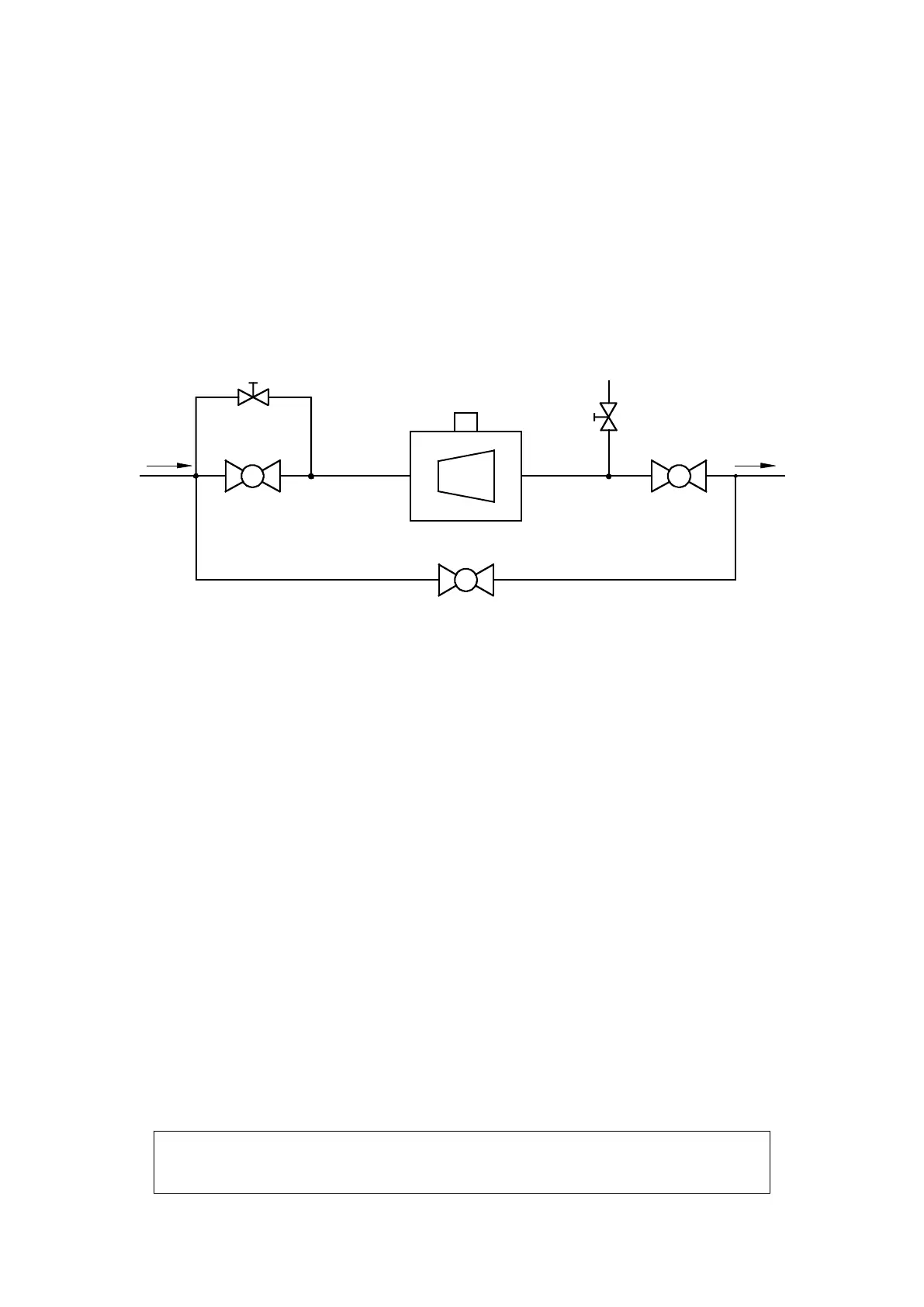

2. After tightening all the bolts connecting the gas meter to the pipework, the air must be

bled from the system (according to appropriate regulations). Open valve 5, while valve 3

is still open.

3. When bleeding is completed, close valve 3 making sure that the pressure increase rate

is not larger than 30 10 kPa/s (adjustment by opening rate of valve 5).

4. When the gas meter counter stops indicating the flow (associated with pressure

equilibration), close valve 5.

5. Open valve 1, then open valve 2.

6. If valve 2 is completely open, bypass valve 4 may be closed.

Fig. 19. A diagram of a measurement system with bypass

When removing the gas meter, the above steps should be followed in reverse order, i.e.:

1. Close bypass valve 4 first.

2. Close valve 2, then close valve 1.

3. Degas the measurement section opening the blow-off valve 3 slowly, that the pressure

drop is not larger than 30 10 kPa/s.

The same principles should be followed in case of any other installation types, i.e. the flow

of the gas through the gas meter should be increased/decreased very slowly. Rapid change

in the flow caused by sudden opening of a valve may damage the measurement turbine

due to excessive difference in pressure upstream and downstream of the rotor.

If there is a risk of a gas meter overload (i.e. exceeding Q

max

by more than 25%) during

its exploitation, the use of a restrictor orifice is recommended. The orifice should be installed

at a distance of 510 nominal diameters (DN) downstream the gas meter. The orifice

dimensions are selected individually on the basis of the nominal diameter and gas flow,

pressure and temperature. Common S.A. may design and deliver appropriate orifice

at customer's request.

Counter readout correctness should be checked after installing the gas meter. Every drum

of the counter should turn smoothly and a full turn of a drum should turn the neighbouring left

drum by 1/10 of a full turn.

Unused electrical output sockets must remain

plugged with factory-made plugs and installation seals.

Loading...

Loading...