34

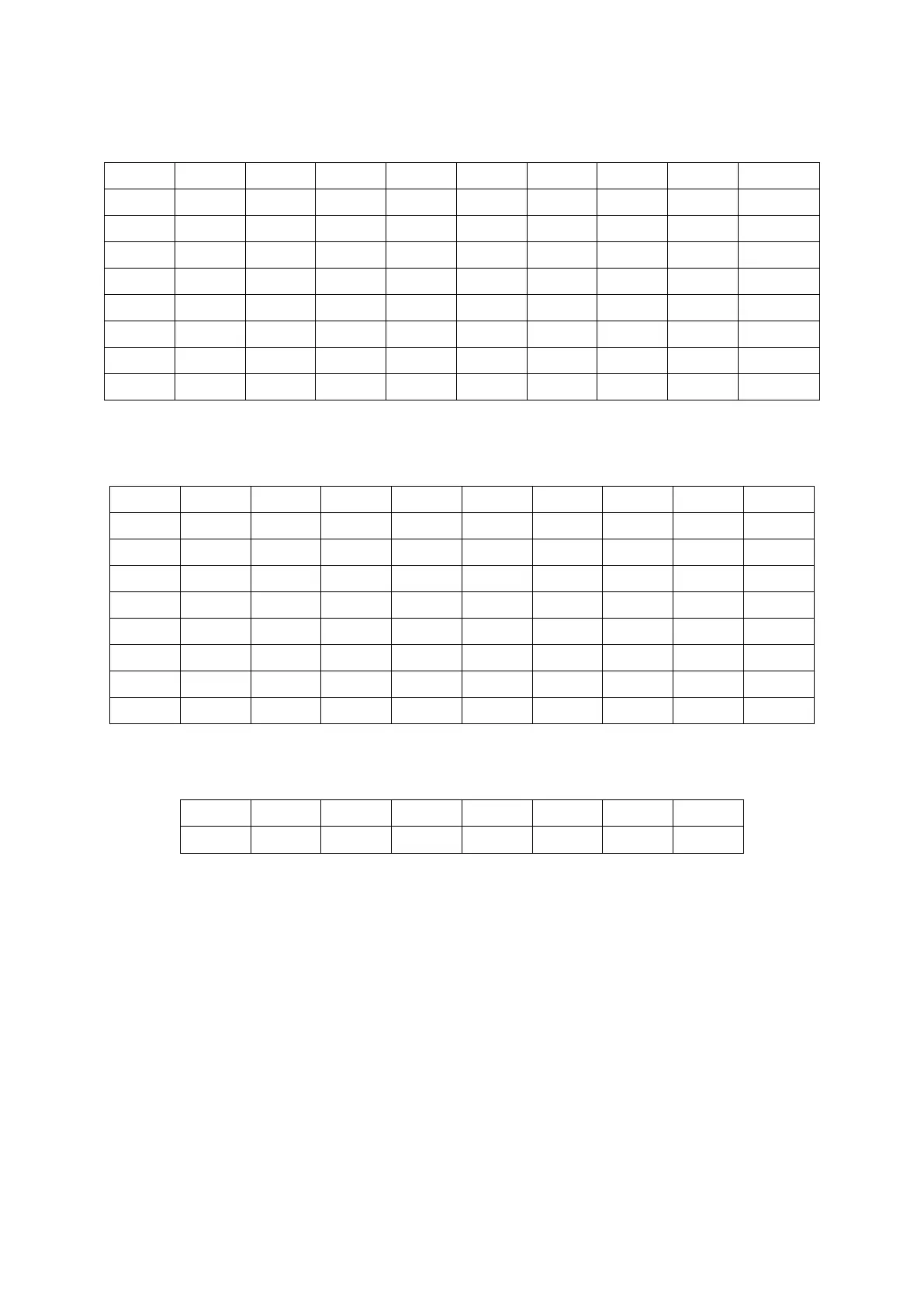

Table 5a. Required tightening bolt torque values for flange connections – smooth, lubricated

threads; M

nom

[Nm].

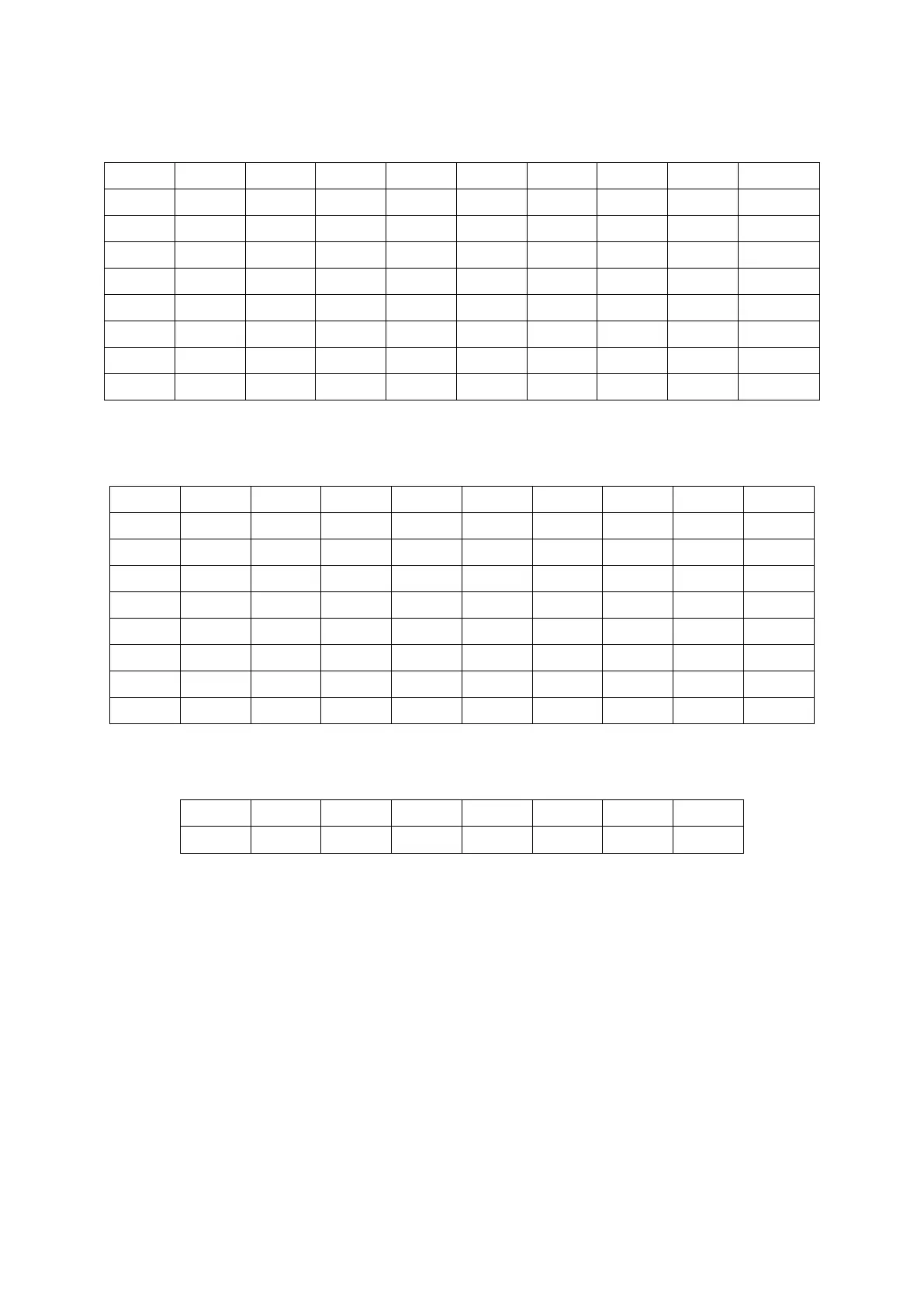

Table 5b. Required tightening bolt torque values for flange connections – smooth,

non-lubricated threads; M

nom

[Nm].

Table 6. Maximum torsional and bending moments exerted by the pipe system on the gas

meter; M

max

[Nm].

Before the first start up of the gas meter installed on the pipework, the oil container should be

filled with oil and the turbine mechanism should be lubricated according to the guidelines

listed in section VII. Only the oil supplied with the gas meter should be used for this purpose.

Following oils may be used with gases listed in Table 1:

Lubrina L12 gas meter oil – distributed by Common S.A.;

Lubrina L23 gas meter oil – distributed by Common S.A.;

VR09 (VELOL 9Q) machinery oil – distributed by Common S.A.;

Shell Tellus T15 hydraulic oil.

In a typical configuration of the gas meter installation, i.e. in a bypass system (Fig. 9),

the gas meter start up procedure should proceed as follows:

1. The installation of the gas meter must be conducted with valves 1, 2, 5 closed

and the bypass valve 4 open. The blow-off valve 3 is left open after the system has been

degassed.

Loading...

Loading...