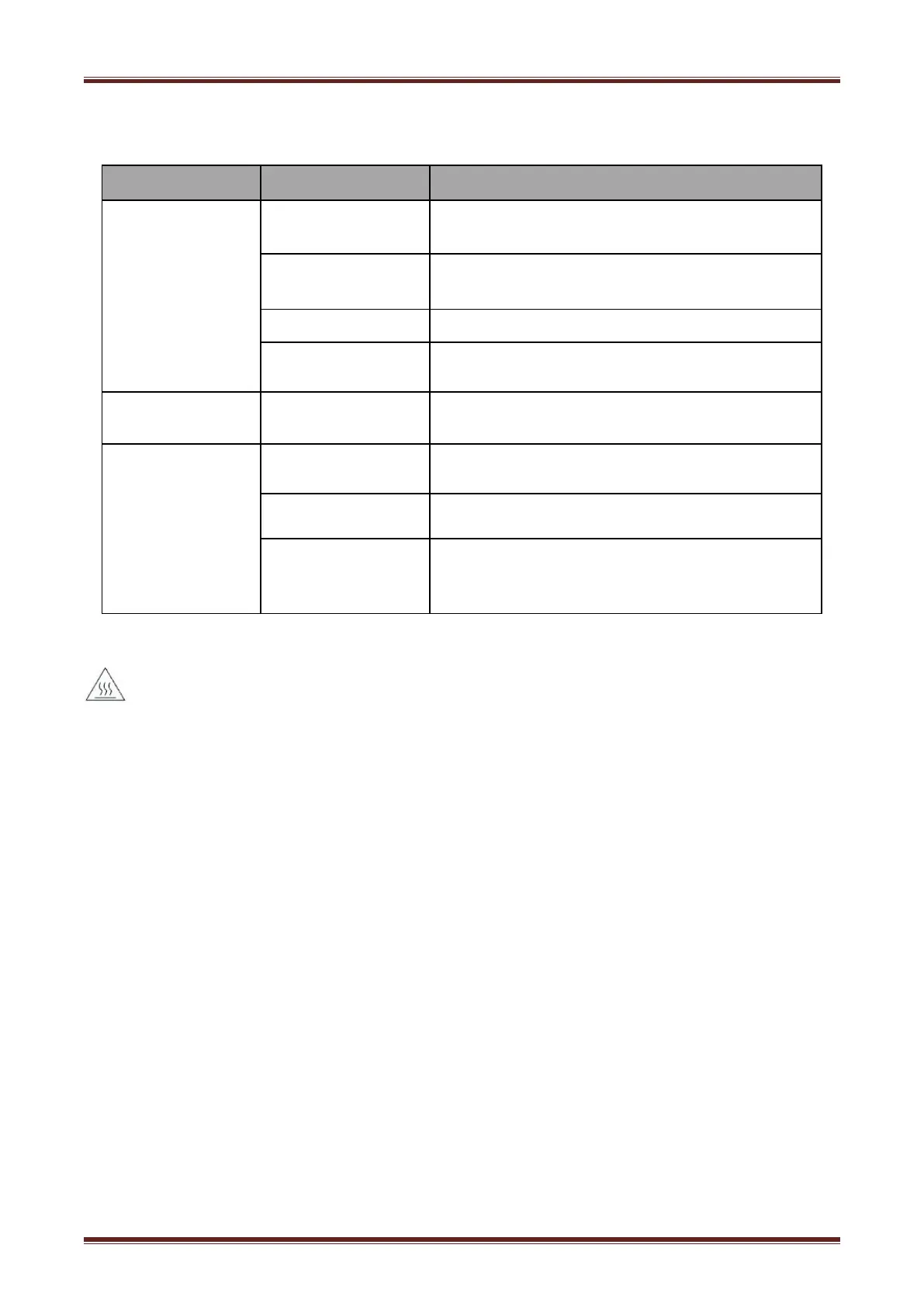

6.4 Problems Emerge During The Paper Cutting Processes

Cutter jam, the

movable cutter cannot

back

Cutter abrasion,

insufficient cutting

Worm gear and worm

wheel abrasion

Replace the worm gear and worm wheel

Clean the paper scraps on the transmission system

Cutter edge abrasion,

paper too thick

Thermal printer head

over heat

Reduce the density of printing

Reduce the printer speed to the limit of thermal printer

head

Wrong paper feeding

position

Put the paper parallel with the paper mount and insert

into the space between platen roller and the thermal

printer head

6.5 Remove Jammed Paper

Warning: Do not touch the thermal print head because it becomes very hot after printing.

If the top cover can be opened,operate it according to the next steps.

1)Turn off the printer and press open cover button.

2)Remove jammed paper, reinstall the roll, and close the cover.

If the auto cutter jam occurs on printer VLINE80-2 and you cannot open the printer cover, open

the cutter cover as shown on the left below.

1)Turn the printer off and open the front cover.

2)Turn the knob until cutter return to the normal position(tip tag).

Loading...

Loading...