18

COMUNELLO ®Copyright 2016 - All rights reserved

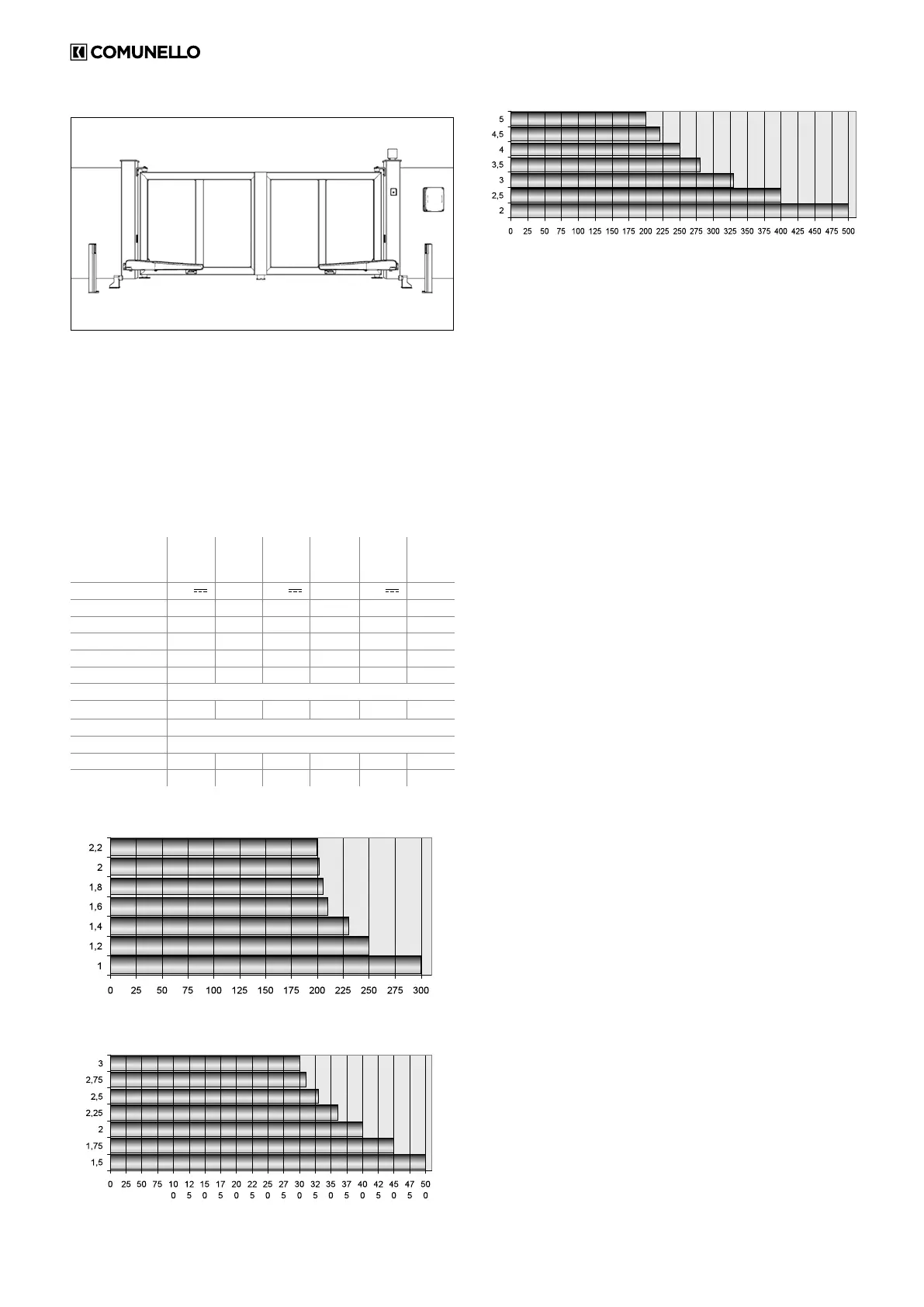

2.2 TYPICAL INSTALLATION

E

C C

F F

G

BB

H

A

D

KEY

A OPERATOR

B OPENING PHOTOCELLS

C CLOSING PHOTOCELLS

D FLASHING LIGHT

E KEY SELECTOR SWITCH

F OPENING LIMIT STOP

G CENTRAL CLOSING STOP

H EXTERNAL CONTROL UNIT

3 PRODUCT TECHNICAL SPECIFICATIONS

ABACUS 220

ABACUS

220 ONE

ABACUS 220 ABACUS 300

ABACUS

300 ONE

ABACUS 500 ABACUS 500

ABACUS

500 ONE

ABACUS 500

Power supply 24V

230V

~

50Hz

24V

230V

~

50Hz

24V

230V

~

50Hz

Operator power supply 70 W 180 W 110 W 280 W 110 W 280 W

Current input 3 A 0,8 A 5 A 1,2 A 5 A 1,2 A

MAXIMUM THRUST 1500 N 1400 N 2000 N 1800 N 2000 N 1800 N

NOMINAL THRUST 500 N 400 N 600 N 700 N 600 N 700 N

Intermittenza di lavoro 30% 0,3 Intensive 0,4 Intensive 0,4

Grado di protezione IP 44 D

Classe di isolamento

II

1 earthing

II

1 earthing

II

1 earthing

Working temperature da -20°C a + 50°C

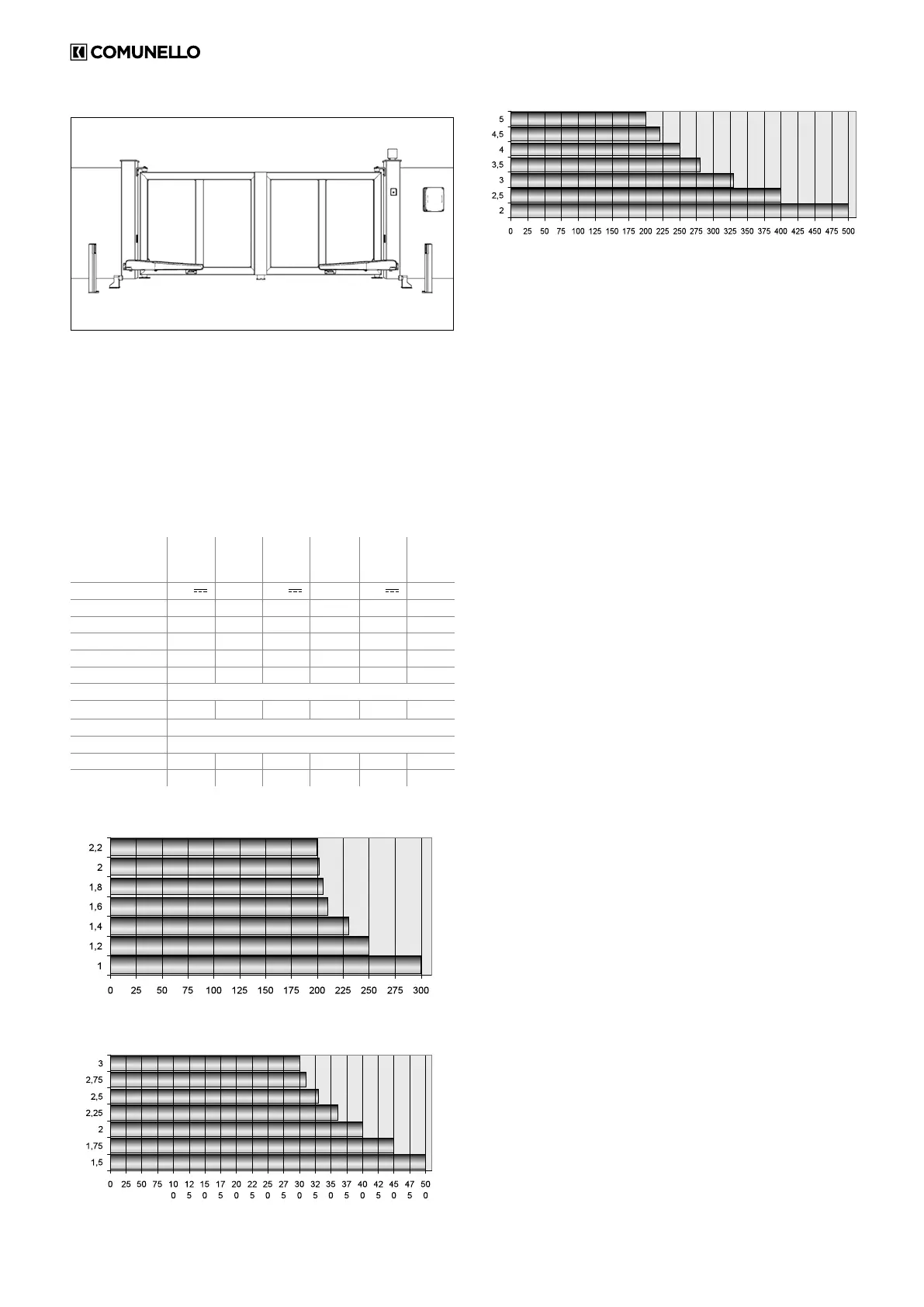

Peso max del cancello SEE THE CHART

Velocità a vuoto 15 mm/s 14 mm/s 22 mm/s 15 mm/s 22 mm/s 15 mm/s

Weight 8,2 Kg 8,6 Kg 11,2 Kg 11,6 Kg 11,9 Kg 12,3 Kg

LEAF WEIGHT (Kg)

LEAF LENGHT (m)

LIMITS OF USE - ABACUS 220

LEAF WEIGHT (Kg)

LEAF LENGHT (m)

LIMITS OF USE - ABACUS 300

LEAF WEIGHT (Kg)

LEAF LENGHT (m)

LIMITS OF USE - ABACUS 500

4 INSTALLATION

4.1 PRELIMINARY CHECKS

Before starting the installation work, check the condition of the product

components, the suitability of the chosen gate operator model and the

suitability of the intended installation environment:

• Ensure that all material used is in perfect condition and t for purpose.

• Make sure that the mechanical structure of the gate is suitable for

automation. This product cannot be used to automate a gate unless the

gate is already in good working order and safe; furthermore, it cannot

remedy defects caused by incorrect installation or lack of maintenance

of the gate.

• Check that the operating conditions of the devices are compatible with

the stated operating limits.

• Move the gate leaves manually in both directions to ensure the force

required is constant throughout the full range of movement.

• Move the gate leaves manually to any position then release them to

check that they remain stationary.

• Check that the area in which the operator is to be mounted is compatible

with the size of the unit and make sure there is sufcient clearance for

the full movement of the arm.

• Ensure that there is sufcient space around the operator to perform the

manual release procedure.

• Ensure that the surfaces on which the devices are to be mounted are

solid and able to provide a secure anchorage.

• Ensure that all devices to be installed are in a sheltered location and

such as to minimize the risk of accidental impact.

4.2 OPERATING LIMITS

Before starting the installation work make sure the operator is correctly sized

in relation to the dimensions and length of the gate leaves and within the

limits of the values given in the chapter “Product technical specications”.

4.3 PREPARATORY WORK FOR INSTALLATION

With reference to gures 1A and 1B, choose the approximate position in

which each component of the system is to be installed and choose the

most appropriate connection layout. List of components required:

• Electromechanical operators

• Pair of photocells

• Pair of opening and closing limit stops

• Posts for photocells

• Flashing light

• Keyswitch or digital keypad

• Vertical electric lock for gate leaves of more than 3 m

• Control unit

4.4 INSTALLING THE ABACUS OPERATOR

4.4.1 INSTALLATION:

• Release the operator as shown in FIG. 2 and FIG. 3.

• Remove the rear cover as shown in FIG. 4.

• Perform the manual release as described in heading 4.4.3.

• Choose the position for the gate operator in correspondence with a

sturdy cross member on the gate.

• Secure plate Z1 to the gate pillar on a provisional basis, orienting it in

accordance with the width of the pillar (FIG. 5A).

• Cut and provisionally x the drilled plate (FIG. 5B) taking account of the

dimensions shown in FIG. 1A and FIG. 1B

• With the gate fully closed, provisionally x plate Z2 to the gate leaf. Weld

the drilled plate (FIG. 5C) observing the dimensions shown in FIG. 1A

and FIG. 1B.

• Couple the operator to the rear bracket using the supplied pin (FIG. 6).

Loading...

Loading...