19

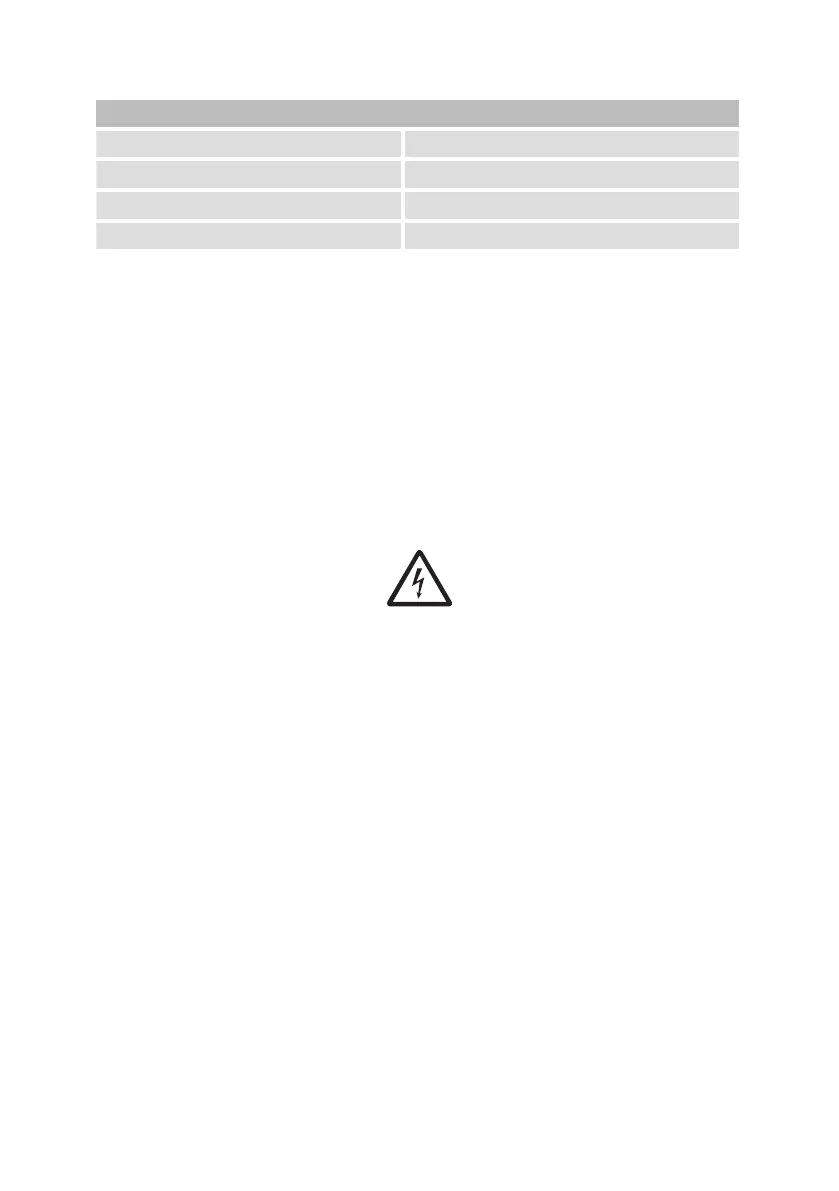

Technical data / Transport / Electrical connection

Materials

Pump housing Polypropylene

Impeller Polyamide

Seals NBR

Motor shaft Stainless steel 1.4028 (AISI 420)

Pump curve – see page 21, figure 1, Dimensions – see page 21, figure 2

5. Transport

Carry the pump by the carrying handle only, not by the electrical connecting cable

or sensor cover. Do not bump or drop it. When lowering the pump into deep

sumps or pits, use a rope or chain.

6. Electrical connection

> Observe the correct operating voltage (see ”Technical data“).

> Never place the power plug in the water.

> Connect the pump to properly installed sockets (in compliance with VDE and

power-supply company regulations) protected by at least 10 A (slow-blowing)

fuses. For submersible pumps of protection class I, all exposed conductive

parts are connected to the protective earth conductor. Before the pump is put

into operation, an electrically skilled person must check that the protective

earth cable is properly connected.

> When operating pumps of protection class I, the following applies according to

IEC 335-2-41:1984, Amendment 1:1990: Pumps of protection class I intended

for use in swimming pools or garden ponds must be equipped with a residual-

current device (max. 30 mA) in the supply line. The pump may not be operated

if any persons are in the pool.

> Temperatures higher than those permitted cause the pump to be shut off by

the temperature monitor. After the temperature monitor is triggered, disconnect

the pump from the electrical system before correcting the cause of the fault, as

otherwise it will switch on automatically once cooled down.

GC-P-FLOW-F-12-1101-JH1.indd 19 24.01.12 09:52

Loading...

Loading...