UNIWORLD Series M/UNIWORLD-M/E ed. 01 2020

WWW.CONFLOW.IT Page 29

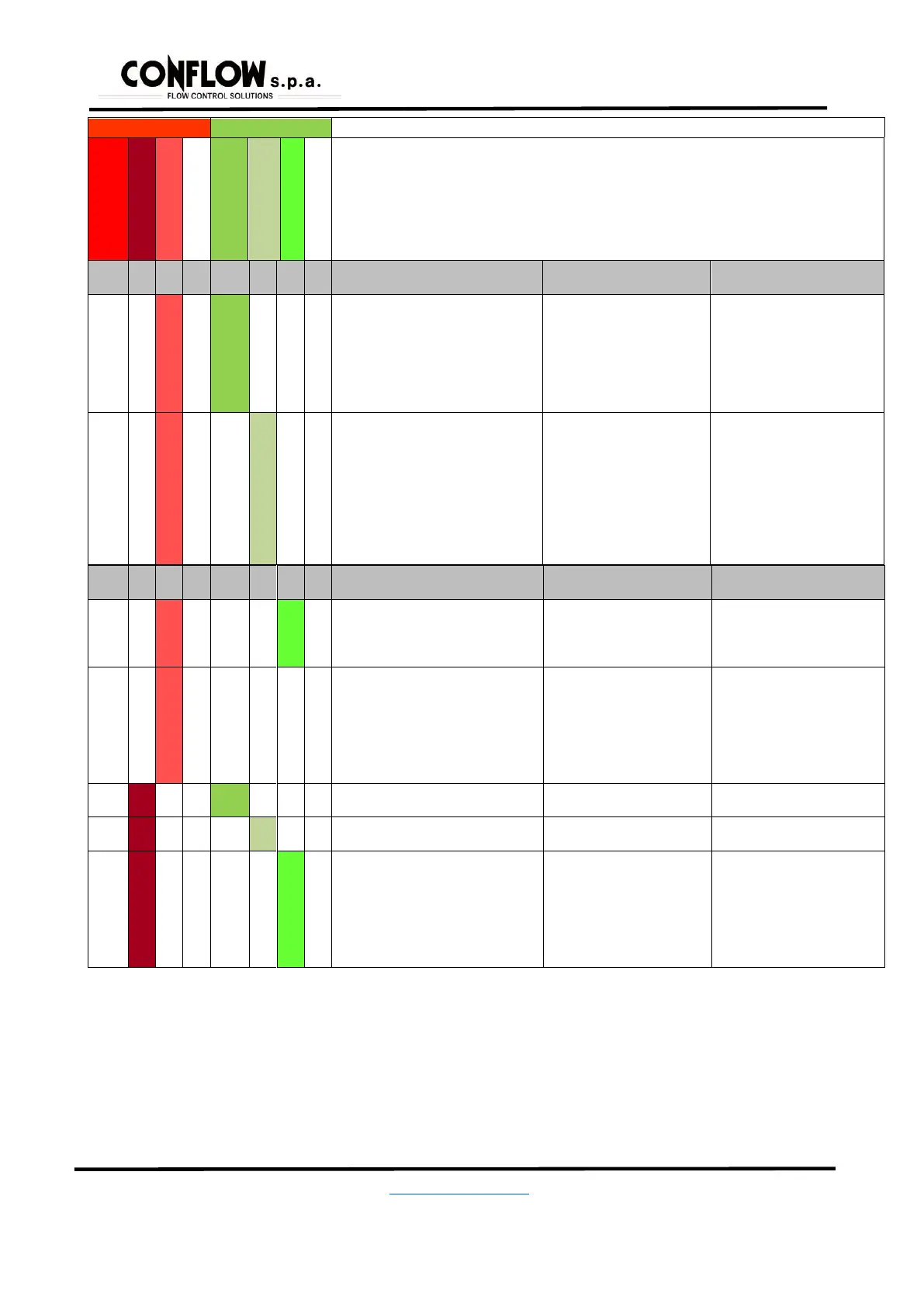

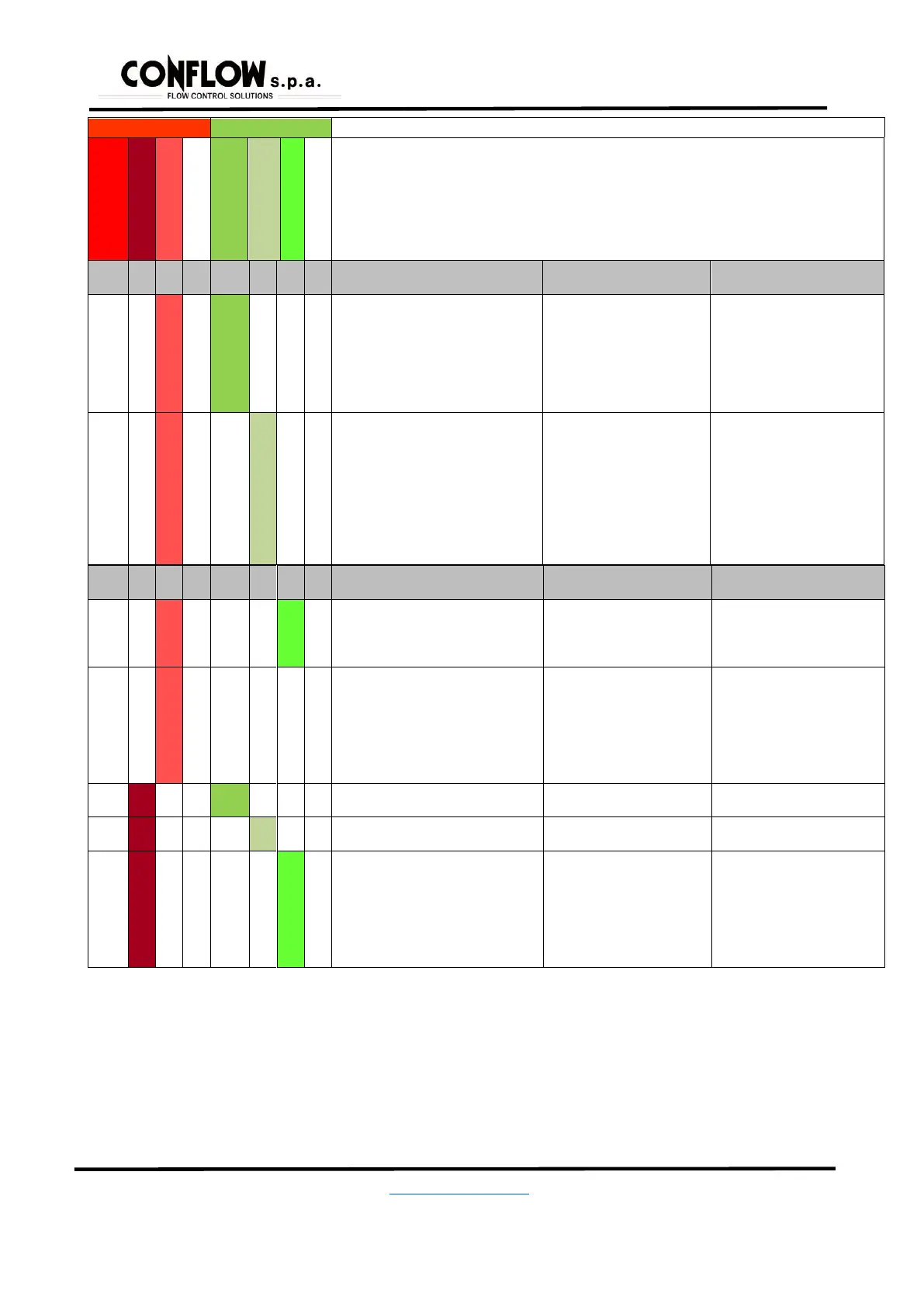

Errors inside actuator

environment

Too much torque in valve stroke

1) The actuator was not

correctly commissioned on

valve

2) There is a mechanical jam

in the stroke

3) Wrong actuator

selection

1) Repeat commissioning

2) Check there are no

obstructions in actuator valve

3) Check actuator selection

1) Inappropriate process feedback(only

combined with PSIC)

2+3) The maximum control range

exceeded (only combined with PSIC)

1) Process feedback

wrong or not connected

2) Process feedback outside

setting range

3) Process sensors not

available

1) Apply the correct

process feedback and

check polarity

2) Ensure correct

feedback range of the

process

3) Check the process sensor

and its power supply

Errors inside actuator

environment

The actuator goes to the

preselected position

1) The safety binary signal

is applied

2) Power supply errors in

actuators with PSCP option

1) Disconnect the signal

2) Check power

supply

Control signal disconnected or outside

range configured

1) Control signal not

connected

2) Wrong polarity of the

control signal

3) Control signal outside range

configured, please check

1) Apply control signal

2) Check polarity signal

3) Check signal range

Final position not reached

Valve seal loose or

dirty

Valve seal worn or

faulty

Actuator power supply too low

1) Power supply wiring

incorrect

2) Power supply

disturbances

3) Voltage too low from PSCP

(with PSCP option)

1) Check power supply

wiring

2) Check

power supply -> see datasheet

3) Contact PS service

team

Loading...

Loading...