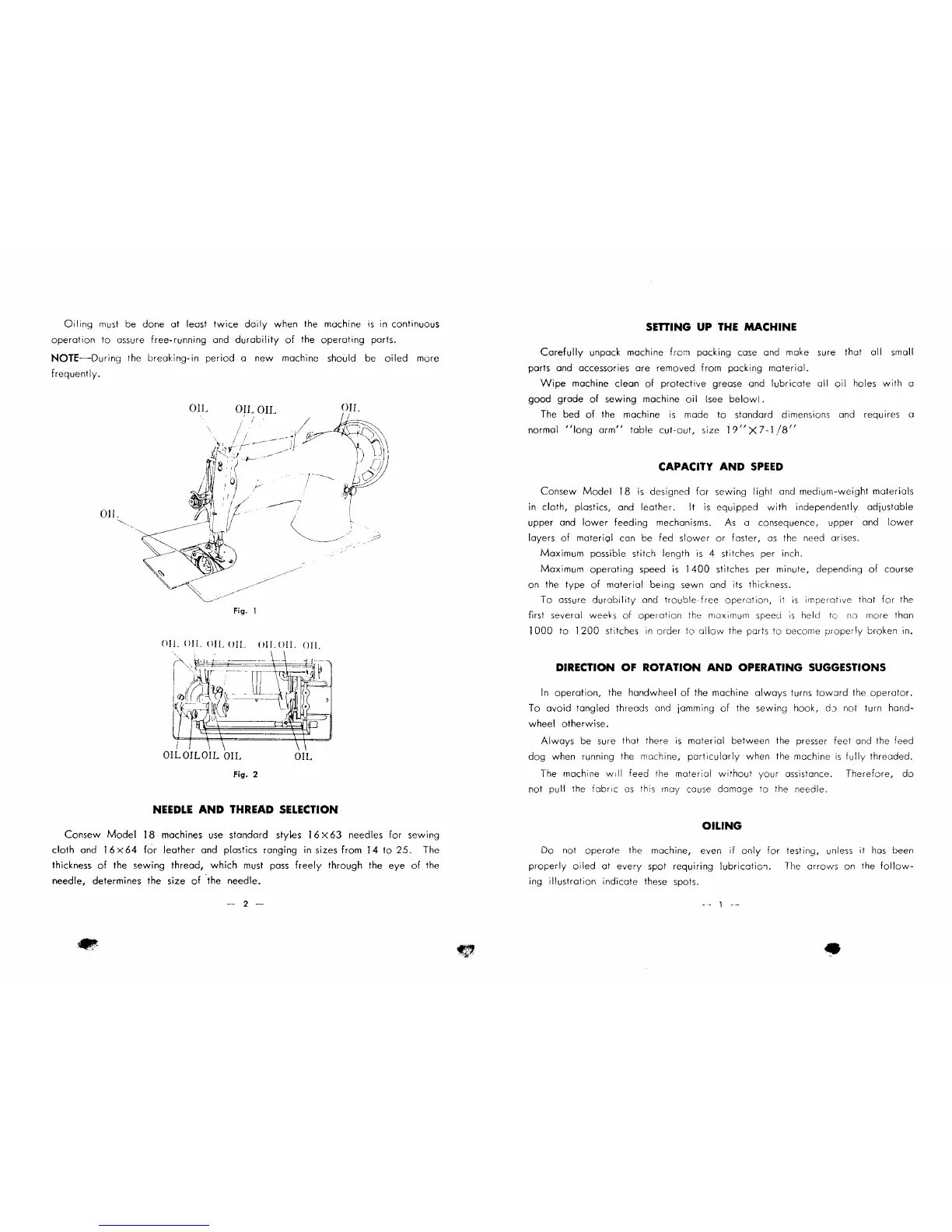

Oiling

must be done

at

least

twice

daily

when

the machine

is

in continuous

operation

to

assure

free-running

and

durability

of

the

operating

ports.

NOTE--During

the

breaking-in

period

a

new

machine should be

oiled

more

frequently.

Oil

OIL

O~I/

OIL

~~OI~L

. /

1/

__.,

\ I /

~----~~

:?: ,

· hr

;-~

~Jl

· ,

'·.~'··I-·

.-~..-'

I

\WJ

I

e

·(

_J1})o

J

;.

,r---.......

'

(?

.

r·

------------,.

- I I

( ;

~.:;::1

~~~--"'

/~~~..-'---

·,

~~

~

Fig.

1

OIL

Oll

OIL OIL

OIL OIL

OIL

~'

'

r~r~~~-w-~_

I

~~(r)~VJ~

---~-

!(

\C

__:]!it(~

'11.~.

)\(~

I

OIL

OIL OIL

OIL

Fig. 2

OIL

NEEDLE

AND

THREAD SELECTION

Consew

Model

I 8 machines use

standard

styles I 6 X

63

needles

for

sewing

cloth

and 1 6 X

64

for

leather

and plastics

ranging

in sizes

from

1 4

to

25.

The

thickness

of

the

sewing

thread,

which

must pass

freely

through

the

eye

of

the

needle,

determines the size

of

.the

needle.

-

2-

•

~

SEniNG

UP

THE

MACHINE

Carefully

unpack machine

fror:1

packing case and make sure that

all

small

ports and accessories

ore

removed from packing

material.

Wipe

machine

clean

of

protective

grease and

lubricate

all

oil

holes

with

a

good

grade

of

sewing

machine

oil

!see

below!.

The bed

of

the machine

is

made

to

standard dimensions and requires a

normal

"long

arm"

table

cut-out,

size

19"X7-1/8"

CAPACITY

AND

SPEED

Consew

Model

18

is

designed

for

sewing

light

and

medium-weight

materials

in

cloth,

plastics, and

leather.

It

is

equipped

with

independently

adjustable

upper and

lower

feeding

mechanisms. As a consequence, upper and

lower

layers

of

materi<;~l

can be fed

slower

or

faster,

as

the need arises.

Maximum

possible stitch length

is

4 stitches per inch.

Maximum

operating

speed

is

1400

stitches per minute, depending

of

course

on the

type

of

material

being

sewn and its thickness.

To

assure

durability

and

troublefrce

operation,

it

is

imperative

that

for

the

first several weeks

of

operation

the maxin1urn speeJ

is

held to no more than

1

000

to

1

200

stitches in

order

to

allow

the parts

to

oecome

oropcr!y

broken in.

DIRECTION OF ROTATION

AND

OPERATING SUGGESTIONS

In

operation,

the handwheel

of

the machine

always

turns

toward

the

operator.

To

avoid

tangled

threads and jamming

of

the sewing hook,

do

not turn

hand-

wheel

otherwise.

Always

be sure that there

is

material

between

the presser feet and the feed

dog

when running the machine,

particularly

when the machine

is

fully

threaded.

The machine

will

feed

the

material

without

your

assistance.

Therefore,

do

not

pull the

iabric

as

this rnay cause damage

to

the needle.

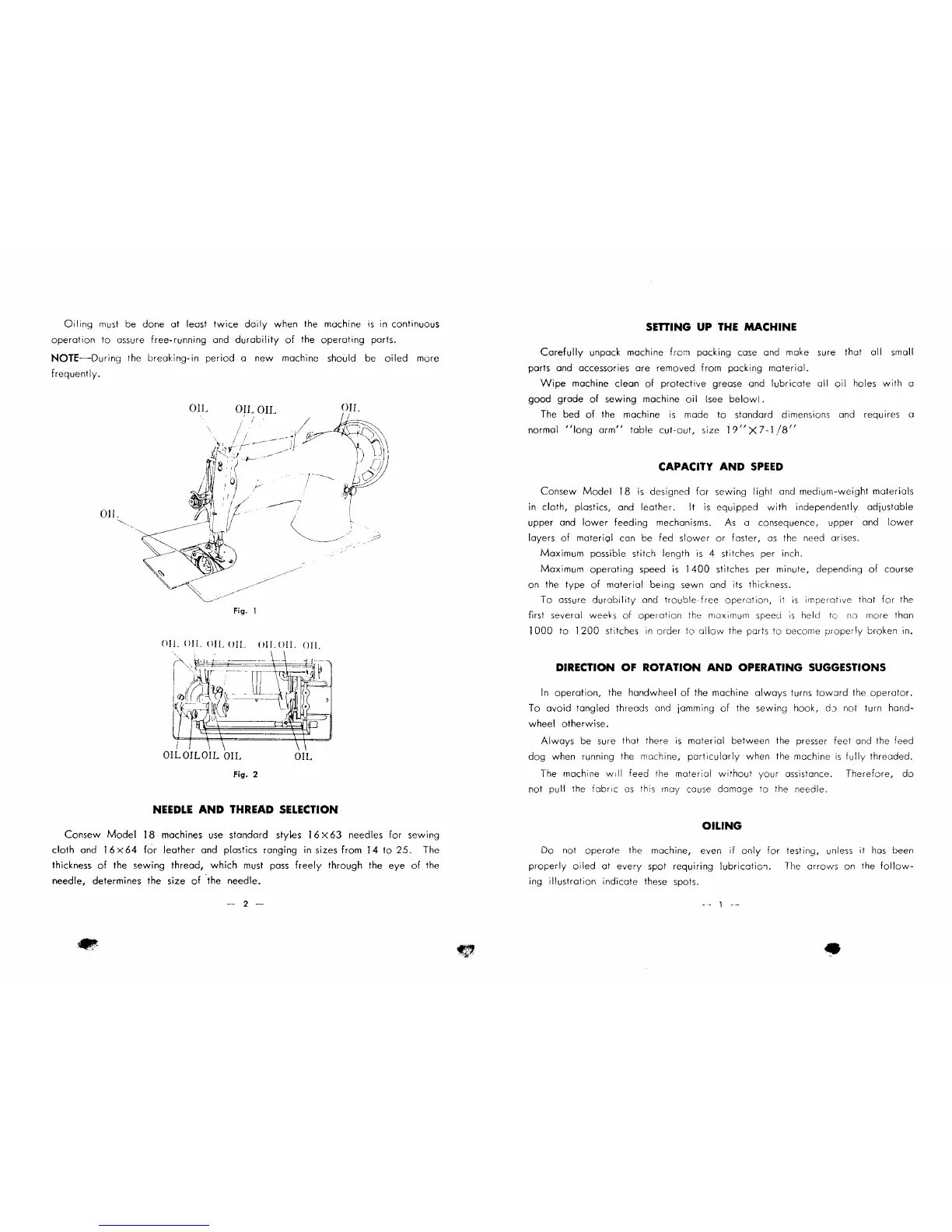

OILING

Do

not

operate

the machine, even

if

only

for

testing, unless

it

has been

properly

oiled

at

every

spot

requiring

lubricatio'1. The

arrows

on the

follow-

ing

illustration

indicate

these spots.

1

--

•

Loading...

Loading...