..

Remember-uneven,

knotted

or

rough thread impairs the satisfactory sewing

performance

of

your

machine.

Only

left twist thread

is

to

be used

for

the needle. To test

for

twist

hold

<=!

length

of

thread between thumbs and index fingers

of

your

hands. Turn

thread counterclockwise.

If

it

will

twist

tighter,

it

has

a

left

twist.

If

it

unravels,

it

has

a right

twist.

The bobbin can be wound

with

either

left

or

right twist thread.

THREADING

THE

NEEDLE

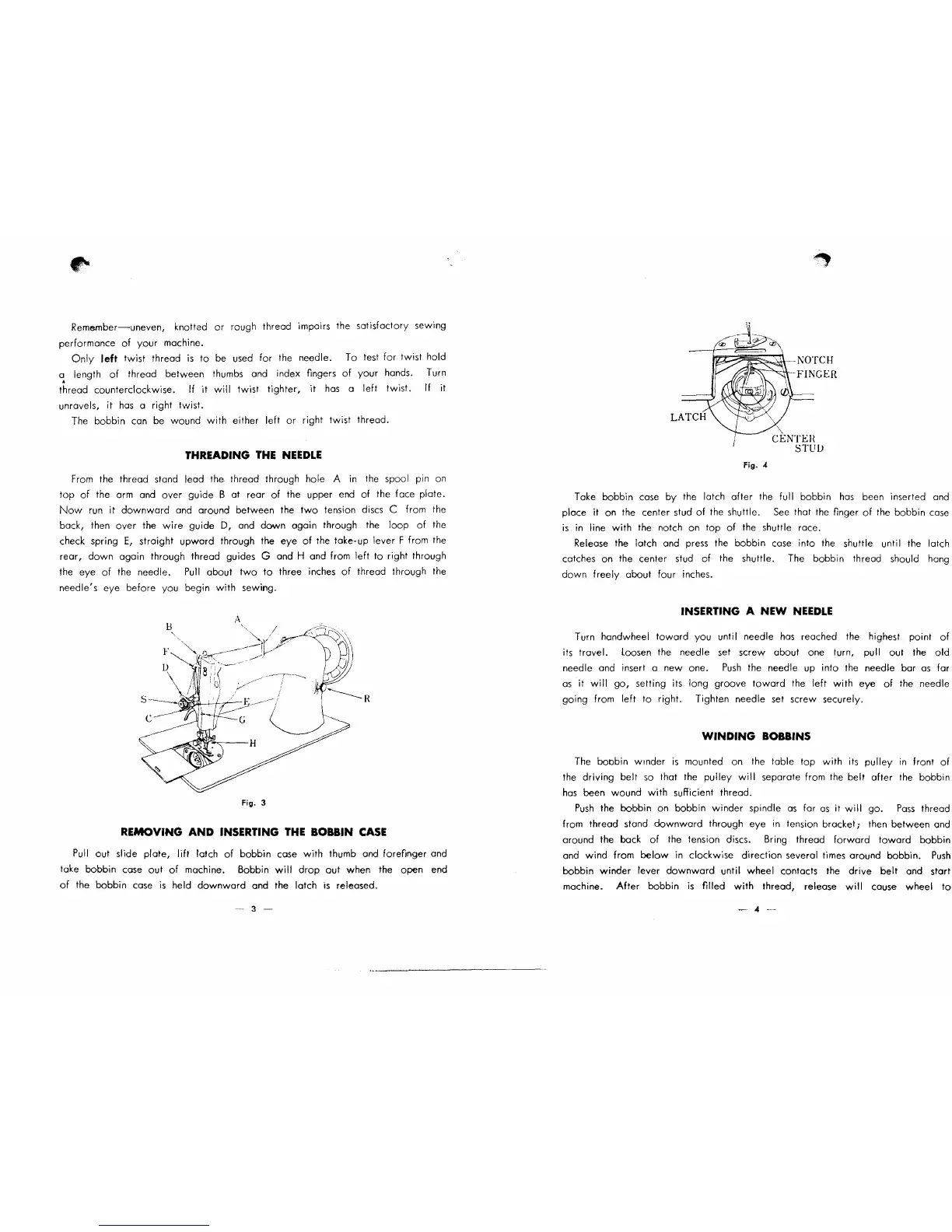

From

the thread stand lead the thread through hole A in the spool pin on

top

of

the arm and

over

guide B at rear

of

the upper end

of

the face plate.

Now

run

it

downward

and around between the

two

tension discs C from the

back, then

over

the

wire

guide

D,

and

down

again through the

loop

of

the

check spring

E,

straight

upward

through the eye

of

the take-up lever F from the

rear,

down

again through thread guides G and H and from

left

to

right through

the eye

of

the needle. Pull about

two

to

three inches

of

thread through the

needle's eye before you begin

with

sewing.

B

Fig. 3

REMOVING

AND

INSERTING

THE

BOBBIN

CASE

Pull out slide

plate,

lift

latch

of

bobbin

case

with

thumb and forefinger and

take bobbin case

out

of

machine. Bobbin

will

drop

out

when the open end

of

the bobbin case

is

held

downward

and the latch

is

released.

3 -

.,...,

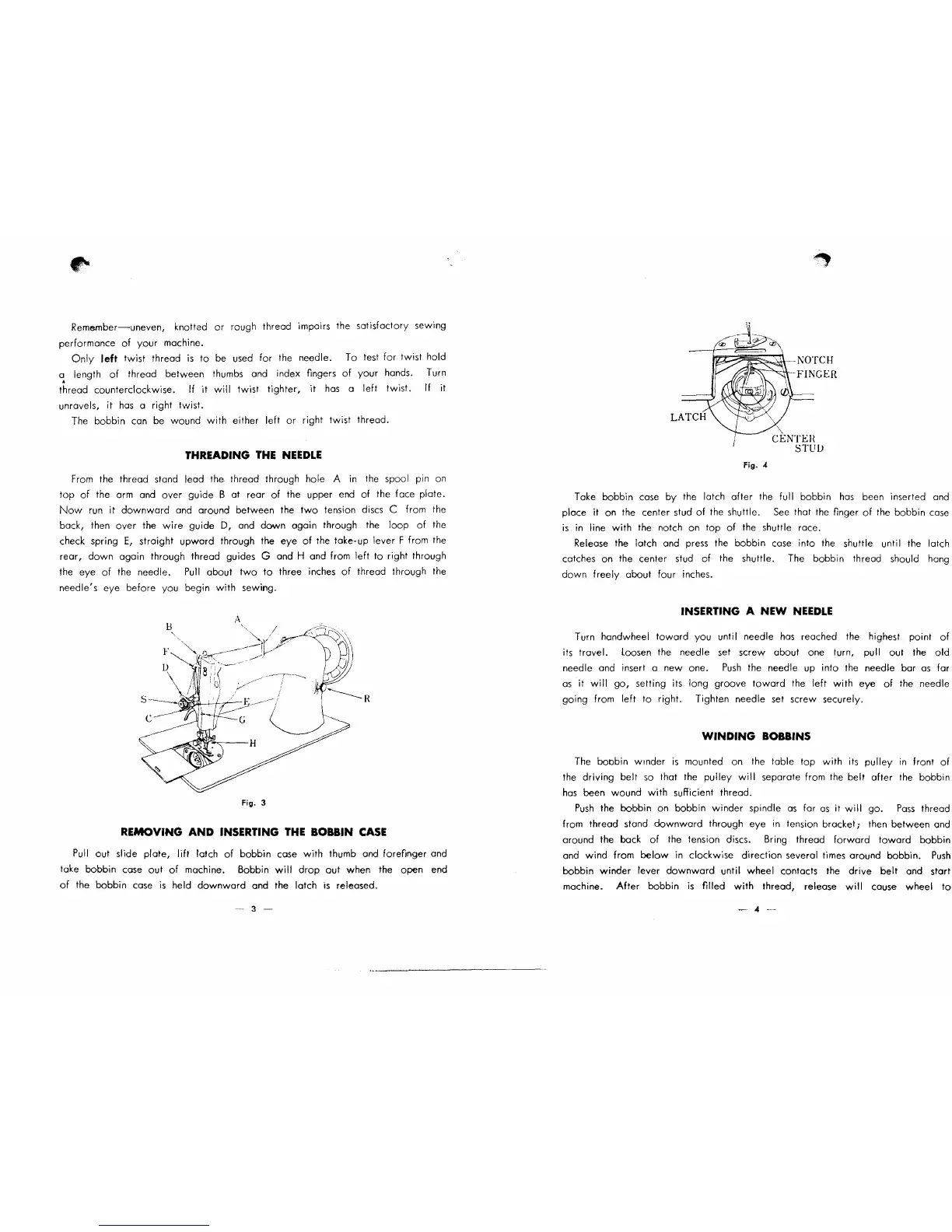

Fig. 4

Take bobbin case

by

the latch

after

the full bobbin

has

been ·Inserted and

place

it

on the center stud

of

the shuttle.

See

that the finger

of

the bobbin case

is

in line

with

the notch on

top

of

the shuttle race.

Release the

latch and press the bobbin case

into

the shuttle until the latch

catches on the center stud

of

the shuttle. The bobbin thread should hang

down

freely

about four inches.

INSERTING A NEW

NEEDLE

Turn handwheel

toward

you until needle

has

reached the highest point

of

its travel. Loosen the needle set screw about one turn, pull

out

the

old

needle and insert a

new

one.

Push

the needle up

into

the needle bar

as

for

as

it

will

go,

setting its long groove

toward

the

left

with

eye

of

the needle

going from

left

to

right. Tighten needle set screw securely.

WINDING

BOBBINS

The

boobin w1nder

is

mounted on the table top

with

its

pulley

in

front

of

the

driving

belt

so

that the

pulley

will

separate from the

belt

after

the bobbin

has

been

wound

with

sufficient thread.

Push

the bobbin on bobbin

winder

spindle

as

far

as

it

will

go.

Pass

thread

from thread stand

downward

through eye in tension

bracket;

then between and

around the bock

of

the tension discs. Bring thread

forward

toward

bobbin

and

wind

from

below

in clockwise

direction

several times around bobbin.

Push

bobbin

winder

lever

downward

until wheel contacts the

drive

belt

and start

machine.

After

bobbin

is

filled

with

thread, release

will

cause wheel

to

-4-

Loading...

Loading...