2

INTRODUCTlON

Service Information S260-20-9 covers

the maintenance instructions for Types

VR VCR, and VLR motor operated oil

switches. This includes their general

description, operating principles and

instructions for periodic inspection, test-

ing, trouble shooting and shop repairs.

A service parts list, keyed to exploded

view drawings of the equipment is

included at the back of the manual.

NOTE: Maintenance instructions for early

(pre1970) versions of these switches is cov-

ered in the original service bulletin 287-

10SB-1.

GENERAL DESCRIPTlON

These oil-filled, electrically-operated

devices provide, three-phase switching

for general purpose loads (Type VR)

capacitive loads (Type VCR) and induc-

tive loads (Type VLR) on manual or

automatic command. These switches

utilize a common operating mechanism

and package configuration, and are dif-

ferentiated by their contact assemblies.

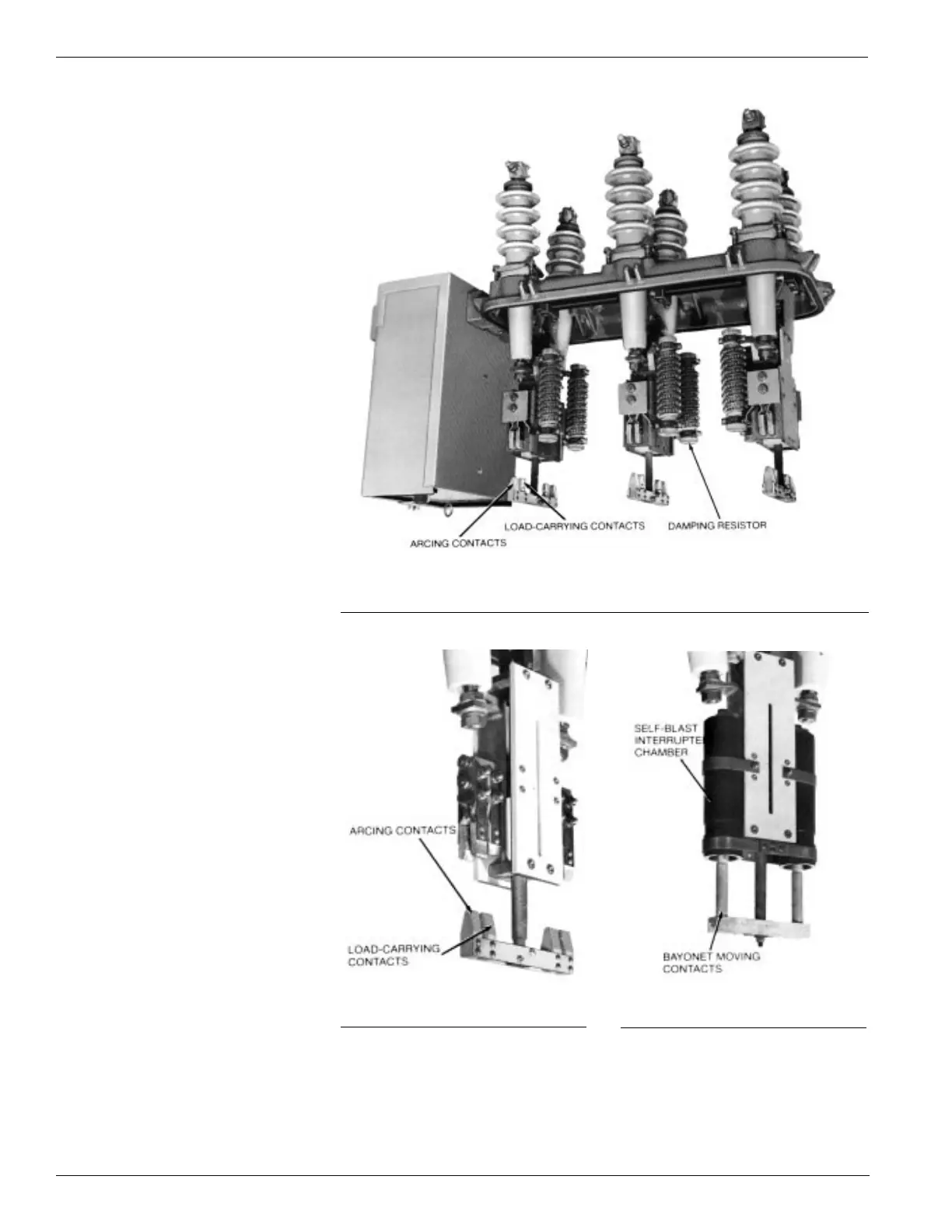

The Type VCR switch utilizes a set of

wedge-shaped moving contacts for arc-

ing and a set of bayonet-type contacts

for load-carrying. In addition, resistors in

series with the arcing contacts damp

both the magnitude and frequency of

transient inrush currents for parallel

capacitor bank switching applications

(Figure 2).

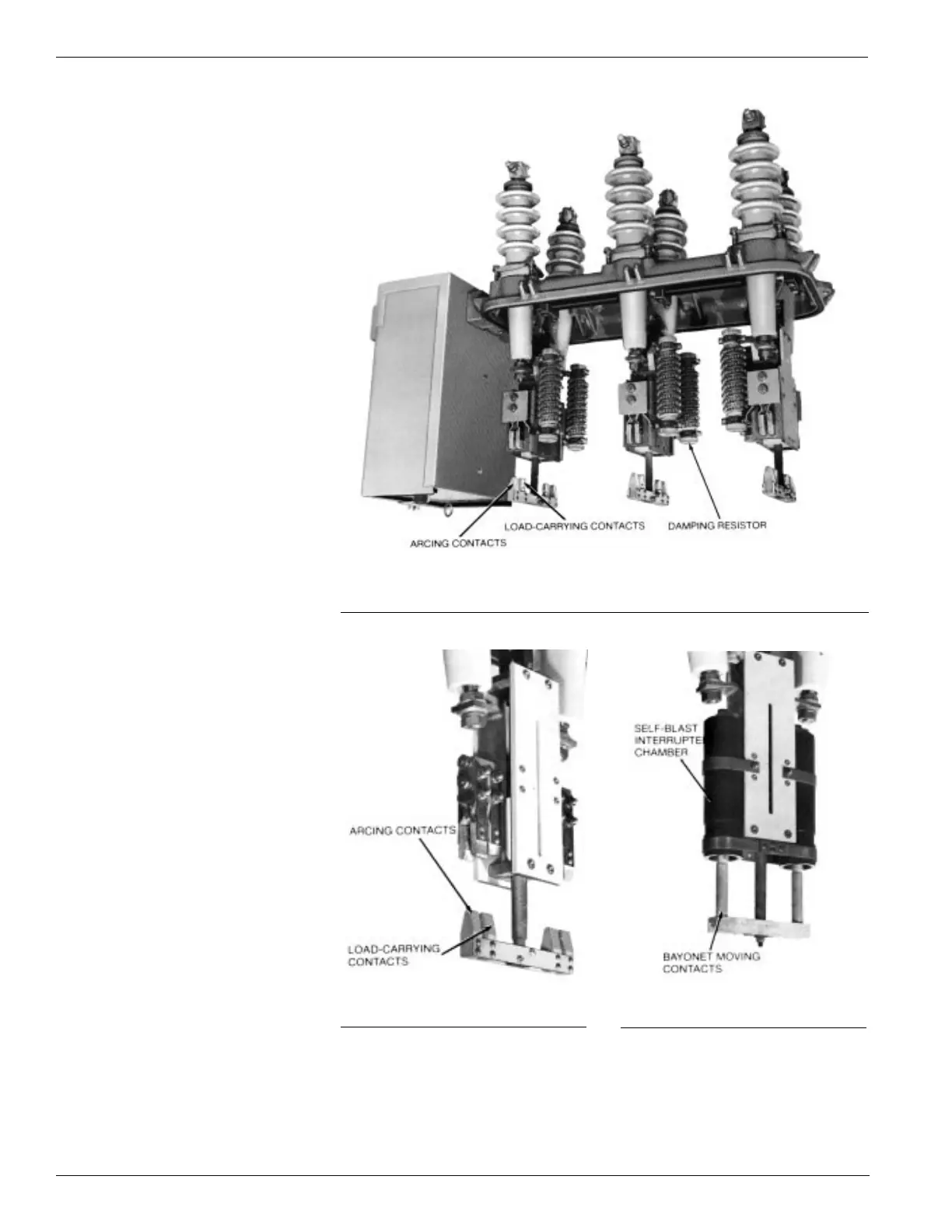

The Type VR switch utilizes two sets

of wedge-shaped moving contacts, one

set for arcing and the second for load-

carrying (Figure 3).

The Type VLR switch utilizes a set of

bayonet-type moving contacts which

operate within self-blast interrupter-

chambers for quick and effective arc

interruption when switching inductive

loads (Figure 4).

The contact structures for all three

phases are linked with bell cranks to a

common torque shaft operated by the

actuator mechanism located in the cabi-

net on the front of the switch.

Figure 2.

Untanked Type VCR switch.

Figure 3.

Type VR contact arrangement.

Figure 4.

Type VLR contact arrangement.

Loading...

Loading...