S260-20-9

5

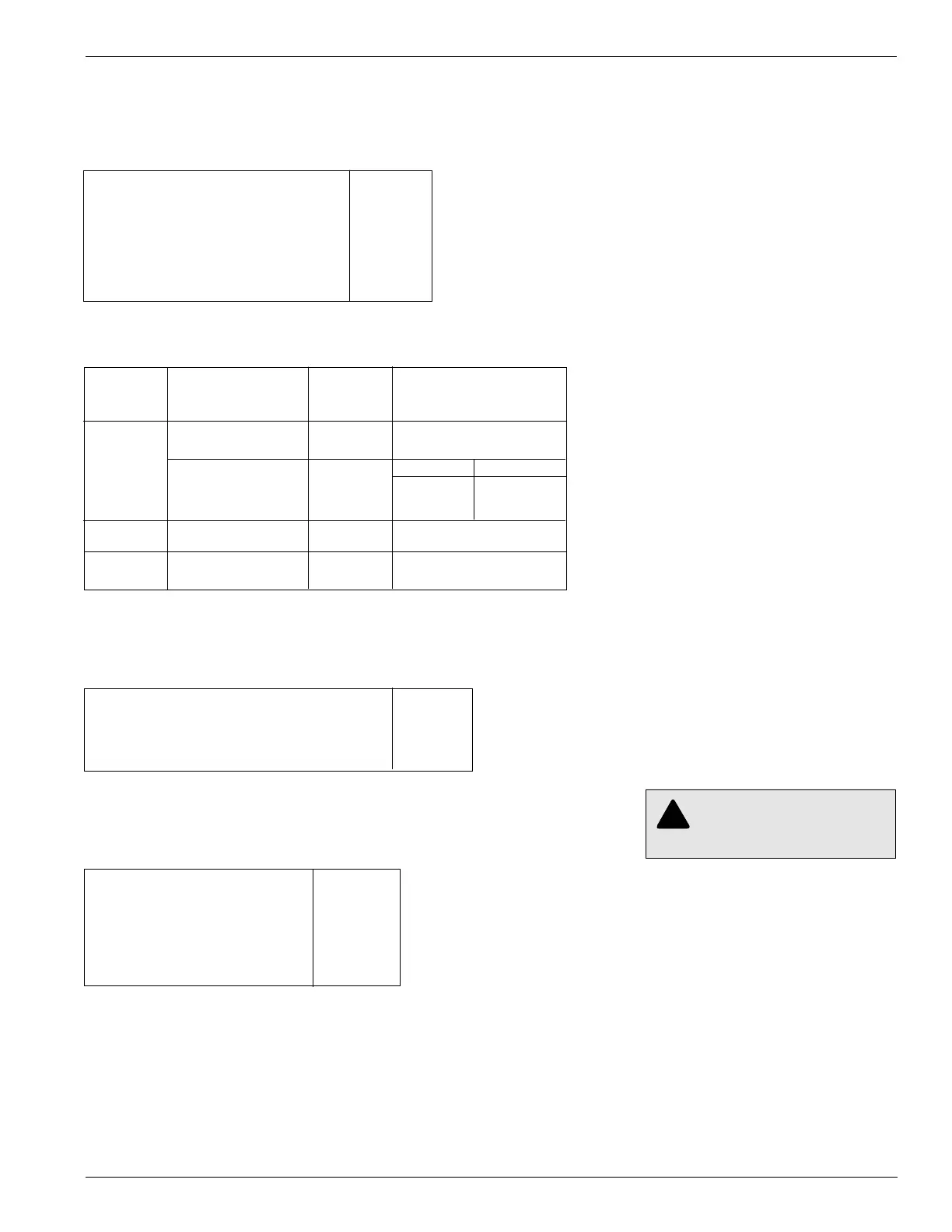

Table 1

Electrical Ratings

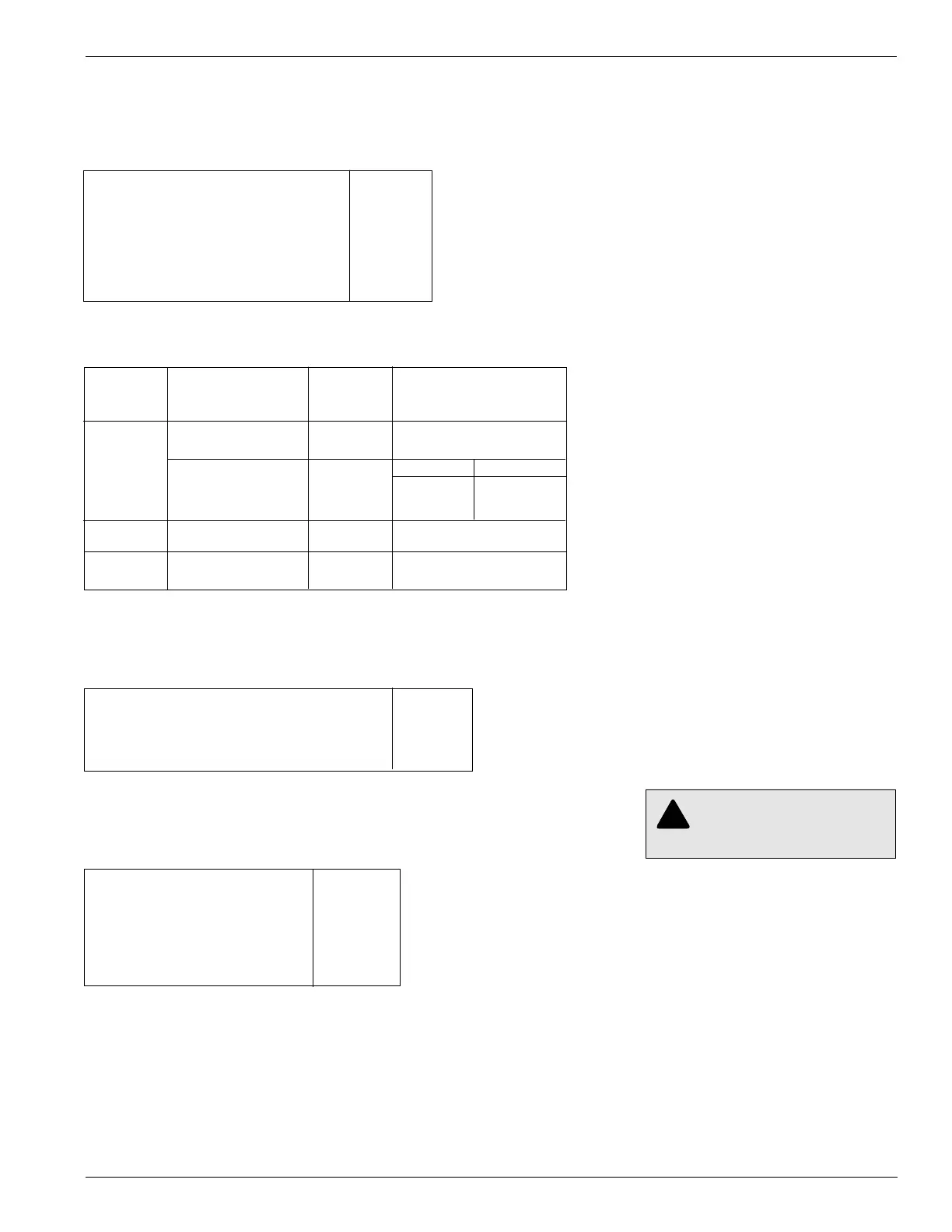

Table 2

Load Switching Ratings

Table 3

Short-Time Current Ratings

Table 4

Actuator Operating Data

CAUTION: Never use

volatile solutions, detergents,

or water-soluble cleaners.

!

RATINGS AND SPECIFICATIONS

Rated maximum voltage (kv rms) 15.5

Nominal system voltage (kv rms) 2.4-14.4

Rated impulse withstand voltage

(BIL) (kv cress) 110

60-Hz insulation level withstand (kv rms)

Dry, 1 minute 50

Wet, 10 seconds 45

Rated continuous current (amps) 400

Rated

Switch Power Current

Type Application Factor (amps)

VR Capacitive current

switching — 300

7.2 kv 14.4 kv

Inductive load 75-100 400 200

switching 50-75 200 100

10-50 100 50

VCR Capacitive current

switching* — 400

VLR Inductive load

switching 10-100 400

Rated momentary asymmetrical current (amps) 20,000

Rated 1/2-second symmetrical current (amps) 13,500

Rated 1-second symmetrical current (amps) 10,000

Rated 4-second symmetrical current (amps) 6,000

Rated asymmetrical making current (amps) 20,000

Closing motor:

Nominal operating voltage (vac) 120

operating voltage range (vac) 95-130

Inrush current (amps) 6

Stead-state current (amps) 3

Running time (see) 10

Trip coil current at 120 vac (amps) 5

MAINTENANCE

Frequency of Maintenance

Because these switches are applied

under widely varying operating and cli-

matic conditions, maintenance intervals

are best determined by the user based

on actual operating experience. Cooper

Power Systems recommends the switch

be inspected and serviced yearly until

experience indicates a more advanta-

geous schedule. In no case should the

service interval extend beyond 1200

operations.

Periodic Maintenance

Inspection

Each periodic maintenance inspection

should include at least the following:

1. By-pass and remove the switch from

service.

2. Inspect external components.

A. Clean the bushings and inspect

for chips, cracks and breaks.

Replace as necessary. (See

page 7 for procedure.)

B. Check for paint scratches and

other mechanical damage. Paint

to inhibit corrosion.

3. Perform a dielectric withstand test to

determine the insulation level. (See

page 6 for procedure.)

4. Loosen the head bolts and remove

the mechanism from the tank. Be

careful not to damage the gasket, if

the tank and head must be pried

apart to break the seal.

5. Allow the oil to drain off the mech-

anism.

6. Clean the internal components.

A. Remove all traces of carbon by

wiping with a clean, lint-free

cloth.

B. Flush the internal components

with clean transformer oil.

7. Check the moving and stationary

contacts.

A. Slight pitting and discoloration can

be dressed with crocus cloth or a

fine-tooth file.

B. Replace

both

the moving and sta-

tionary contacts if they are

severely eroded. (See page 7 for

procedures.)

NOTE: The contacts should be

replaced before erosion of the load-

current transfer surfaces impairs their

effectiveness.

8. Manually close and trip the switch

several times to check that all com-

ponents perform properly. (See page

6 for manual closing procedure.)

9. Inspect the tank wall liners. Soft or

spongy areas indicate that water has

Loading...

Loading...