Balance Carbonator / Balance Karbonator

Manual operation / Gebrauchsanweisung

Carbonator/Karbonator HS/HK

Seite

13

Cornelius Deutschland GmbH

Document no/ Dokumenten-Nr.: TD22022600ML

Version A, 11.05.2020, Index 0

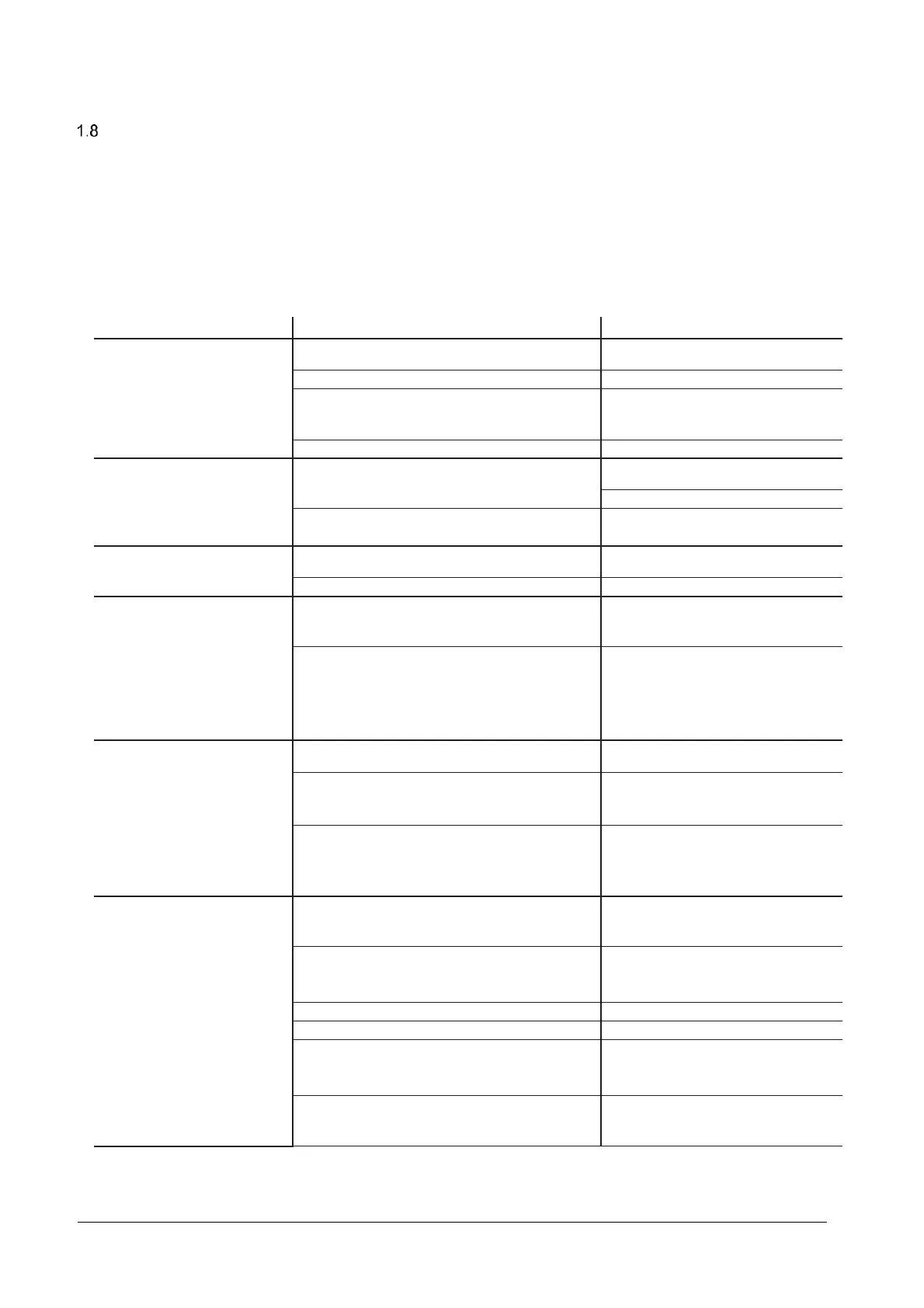

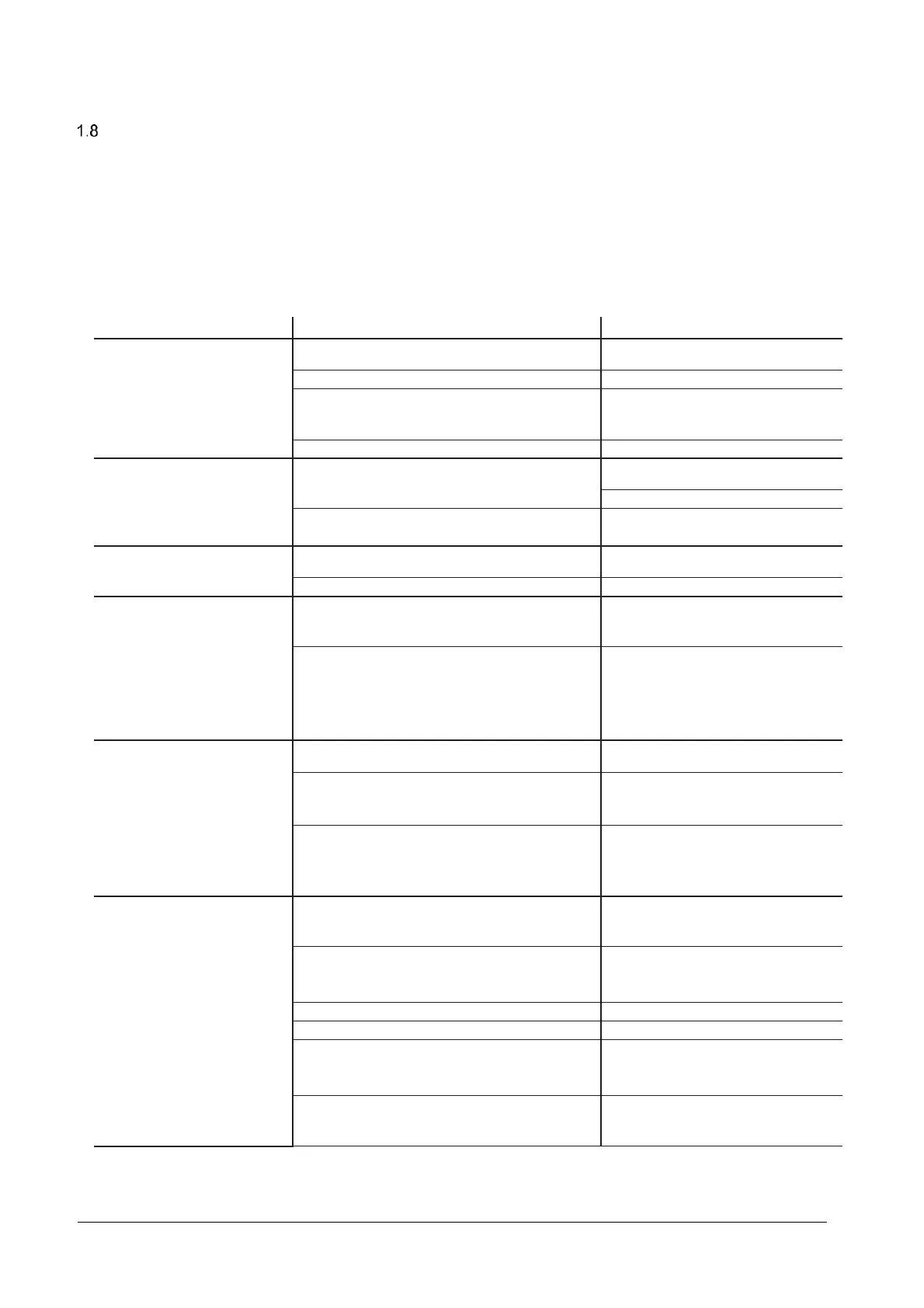

Problems and Troubleshooting

Before looking for problems with the dispensing equipment,

first check:

–

Is the flow of electricity to the device interrupted?

–

Is the flow of water to the device interrupted?

–

Are the beverage containers empty?

–

Is the CO

2

-cylinder empty?

Carbonator pump does

not start

Unit not connected to electricity

plug in power supply plug

water pressure regulator out of adjustment

–

pressure too low

adjust flow pressure: 2 bar

Carbonator pump does

not start at output of

stillwater

Cable to stillwatertap interrupted

Check connecting cable and

24 V provision interrupted

Check transformer and if defect

change

Carbonator pump does

not stop

compounds for electrode interrupted

controlling electronic defect

Carbonator pump starts

and stops

high water pressure variations

Check flow pressure 2 bar or lay

new water connection

Electric connections mixed up

Electric connections are marked

with colours: connect red

connection with red cable and

orange connection with orange

cable

CO

2

carbonation pressure to low

Pressure of pump too low

Increase carbonation pressure

Set in pressure of pump, 11-12

bar

Impact pressure of pump Lay

new

CO

2

line or check reduction of

lateral section in the CO

2

system

Check carbonation pressure 5-

5,5 bar

Syrup contains CO

2

either due to too high

lifting pressure or keeping Syruptanks in

cooling cave

Set syrup lifting pressure approx.

3-

3,5 bar

Syrup is seeding, tank not clean

Release of Carbon dioxide in water

Distance from cooling unit to

dispensing head without python:

max. 2 m

As lines from cooling unit to dispensing

head

either too long or not insulated.

Loading...

Loading...