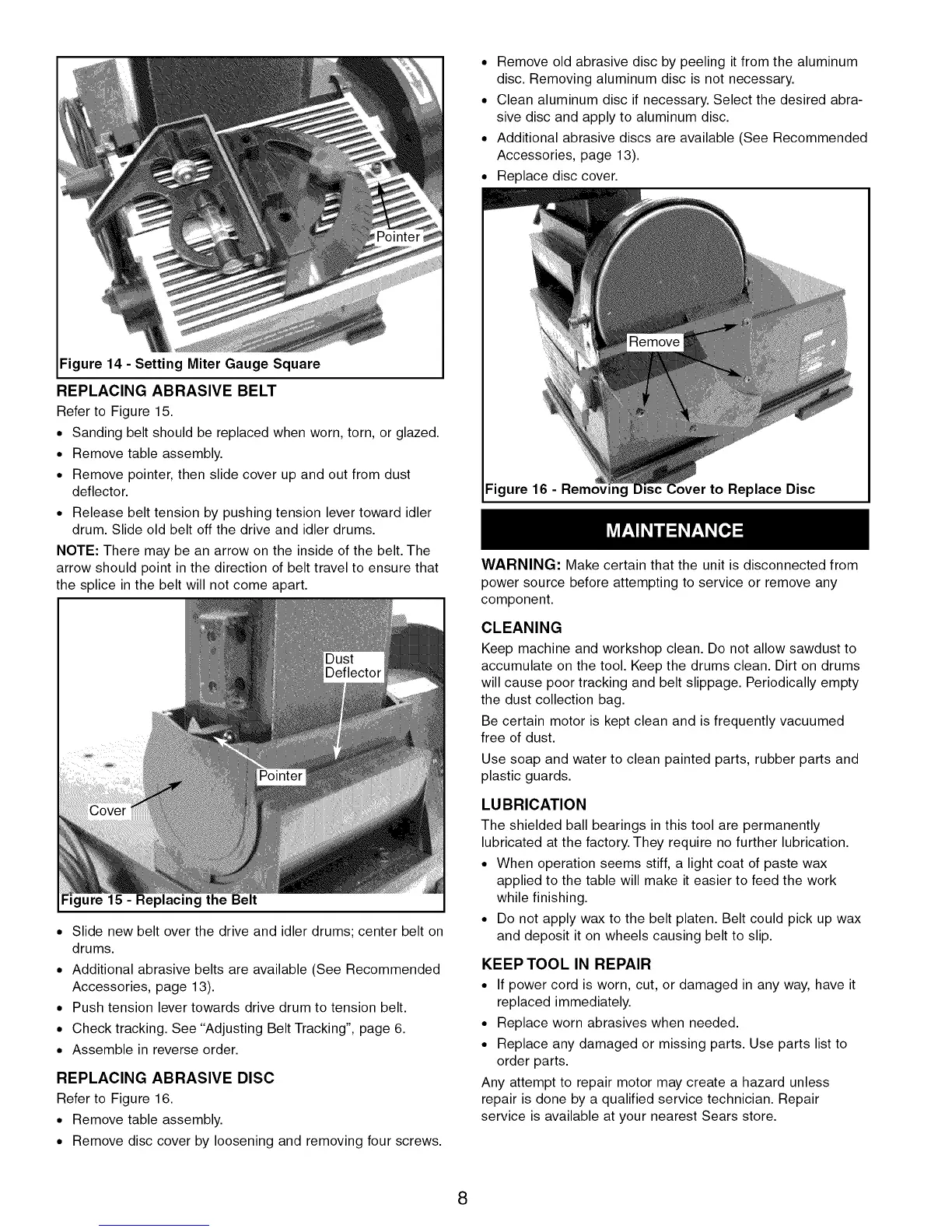

Figure 14 - Setting Miter Gauge Square

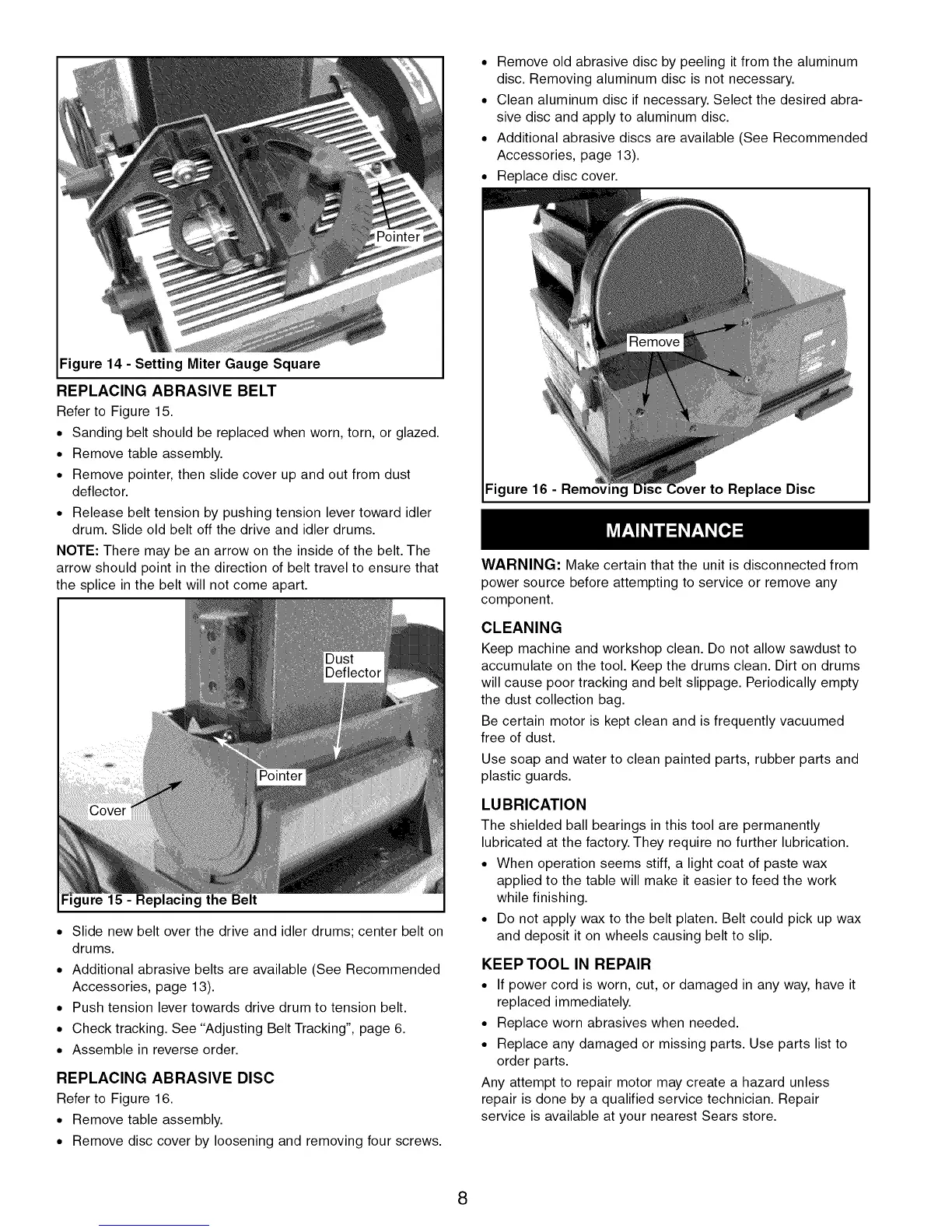

REPLACING ABRASIVE BELT

Refer to Figure 15.

• Sanding belt should be replaced when worn, torn, or glazed.

• Remove table assembly.

• Remove pointer, then slide cover up and out from dust

deflector.

• Release belt tension by pushing tension lever toward idler

drum. Slide old belt off the drive and idler drums.

NOTE: There may be an arrow on the inside of the belt. The

arrow should point in the direction of belt travel to ensure that

the splice in the belt will not come apart.

Figure 15 - Replacing the Belt

• Slide new belt over the drive and idler drums; center belt on

drums.

• Additional abrasive belts are available (See Recommended

Accessories, page 13).

• Push tension lever towards drive drum to tension belt.

• Check tracking. See "Adjusting Belt Tracking", page 6.

• Assemble in reverse order.

REPLACING ABRASIVE DISC

Refer to Figure 16.

• Remove table assembly.

• Remove disc cover by loosening and removing four screws.

• Remove old abrasive disc by peeling it from the aluminum

disc. Removing aluminum disc is not necessary.

• Clean aluminum disc if necessary. Select the desired abra-

sive disc and apply to aluminum disc.

• Additional abrasive discs are available (See Recommended

Accessories, page 13).

• Replace disc cover.

Figure 16 - Removing to Replace Disc

WARNING: Make certain that the unit is disconnected from

power source before attempting to service or remove any

component.

CLEANING

Keep machine and workshop clean. Do not allow sawdust to

accumulate on the tool. Keep the drums clean. Dirt on drums

will cause poor tracking and belt slippage. Periodically empty

the dust collection bag.

Be certain motor is kept clean and is frequently vacuumed

free of dust.

Use soap and water to clean painted parts, rubber parts and

plastic guards.

LUBRICATION

The shielded ball bearings in this tool are permanently

lubricated at the factory. They require no further lubrication.

• When operation seems stiff, a light coat of paste wax

applied to the table will make it easier to feed the work

while finishing.

• Do not apply wax to the belt platen. Belt could pick up wax

and deposit it on wheels causing belt to slip.

KEEP TOOL IN REPAIR

• If power cord is worn, cut, or damaged in any way, have it

replaced immediately.

• Replace worn abrasives when needed.

• Replace any damaged or missing parts. Use parts list to

order parts.

Any attempt to repair motor may create a hazard unless

repair is done by a qualified service technician. Repair

service is available at your nearest Sears store.

8

Loading...

Loading...