Do you have a question about the Craftsman ACCRA-ARM 113.29402 and is the answer not in the manual?

Details motor specs (voltage, amps, RPM) and connection diagrams for power supply.

Covers thermal overload protector, fuses, and general electrical safety.

Provides wire size recommendations and diagrams for 115V and 230V connections.

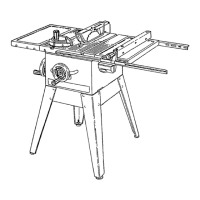

Instructions for securing the saw base to a sturdy work bench.

Steps for attaching the front table, aligning holes, and securing with hardware.

Procedure for leveling the table relative to the radial arm using set screws.

Steps to reduce or remove looseness in the radial arm movement.

How to ensure the blade's cross-cut path is square to the rip fence.

Procedure to check and correct for blade alignment issues with the fence.

Steps for setting up the saw for initial cross-cutting operations.

Instructions for safely installing and removing the saw blade.

Explains key/switch, arm latch, carriage lock, and motor yoke positioning.

Adjusting the yoke for ripping positions and setting rip scale indicators.

Procedures for adjusting components to account for wear and maintain accuracy.

How to adjust carriage for looseness and safety advice for operator attire.

Specifies points requiring lubrication with SAE 10-30 oil and points not to lubricate.

Detailed steps and safety for performing cross-cut operations.

Guide to performing ripping operations with the saw in different configurations.

Instructions for cutting thick boards into thinner pieces.

Procedures for making various angled and specialized cuts using different blades.

Using the saw for routing, drilling, and sanding operations with attachments.

Advice on blade washers, brake function, and general maintenance tips.

Methods for fixing a warped fence and extending saw table life.

| Model | 113.29402 |

|---|---|

| Voltage | 120 V |

| Amps | 15 A |

| No Load Speed | 5000 RPM |

| Blade Diameter | 10 inches |

| Arbor Size | 5/8 inches |

| Bevel Range | 0-45 degrees |