Software Operation

Right Click on Model

3

4

Red represents "outer shell"

Green represents "inner shell"

Yellow represents "infill"

Purple represents "bottom and top shell"

Blue represents "support"

Toolpath Structure

Drag layer indicator can browse different

level paths, Ctrl + arrow keys to browse layer by

layer. 3D printing is the superposition of these

different layers and built layer by layer.

4

6

5

2

3

1

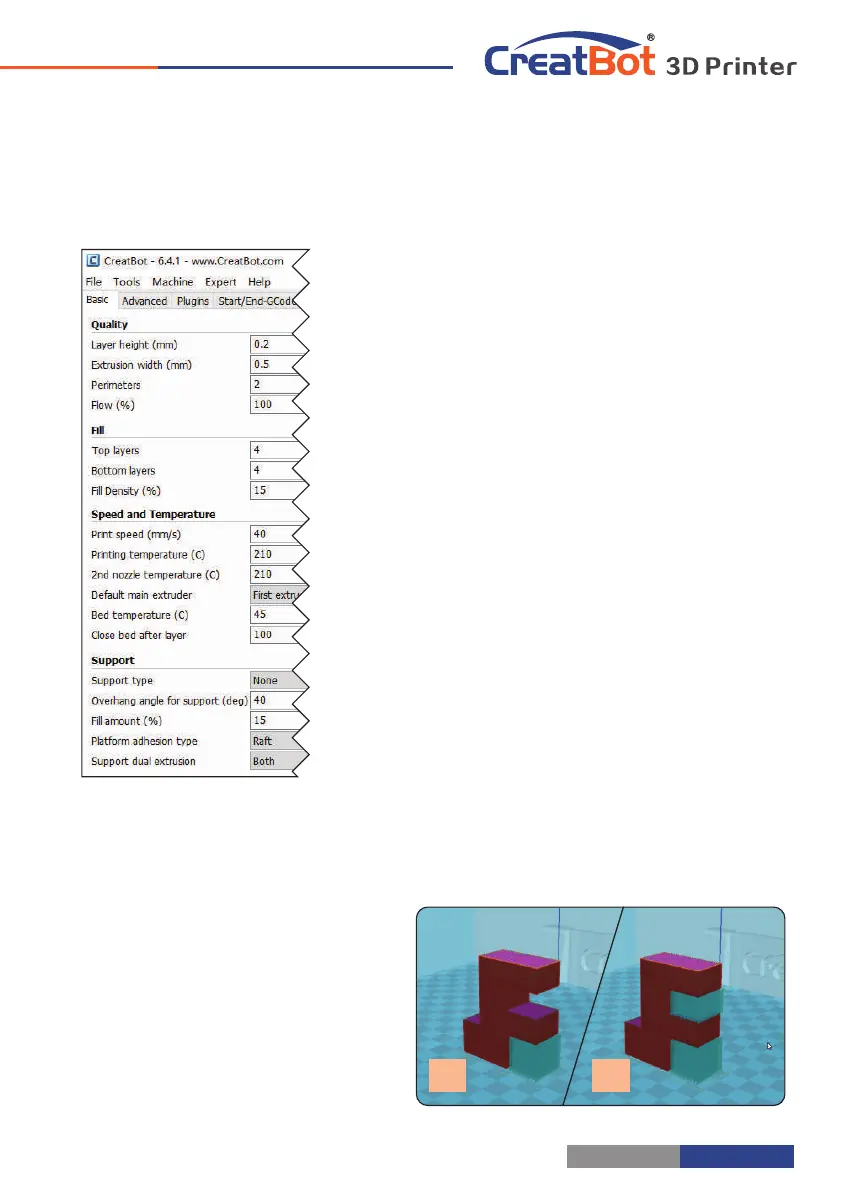

Right-click on the model pop-up shortcut

menu, here are more features:

[1] "Centered" make the model back to the

center position of the platform. "Delete" to [2]

remove the currently selected model. "Multiply" [3]

to copy the currently selected model and

automatically position, which is useful for printing

more than one model at a time. "Split" multi-[4]

component model can be split into its separate components, this process more time-

consuming, try to split the model in the modeling software, models splited can be

printed individually and then assembled together . "Delete All" to delete all the [5]

models loaded. "Reload all" Reload all models, same as F5.[6]

- 26 -

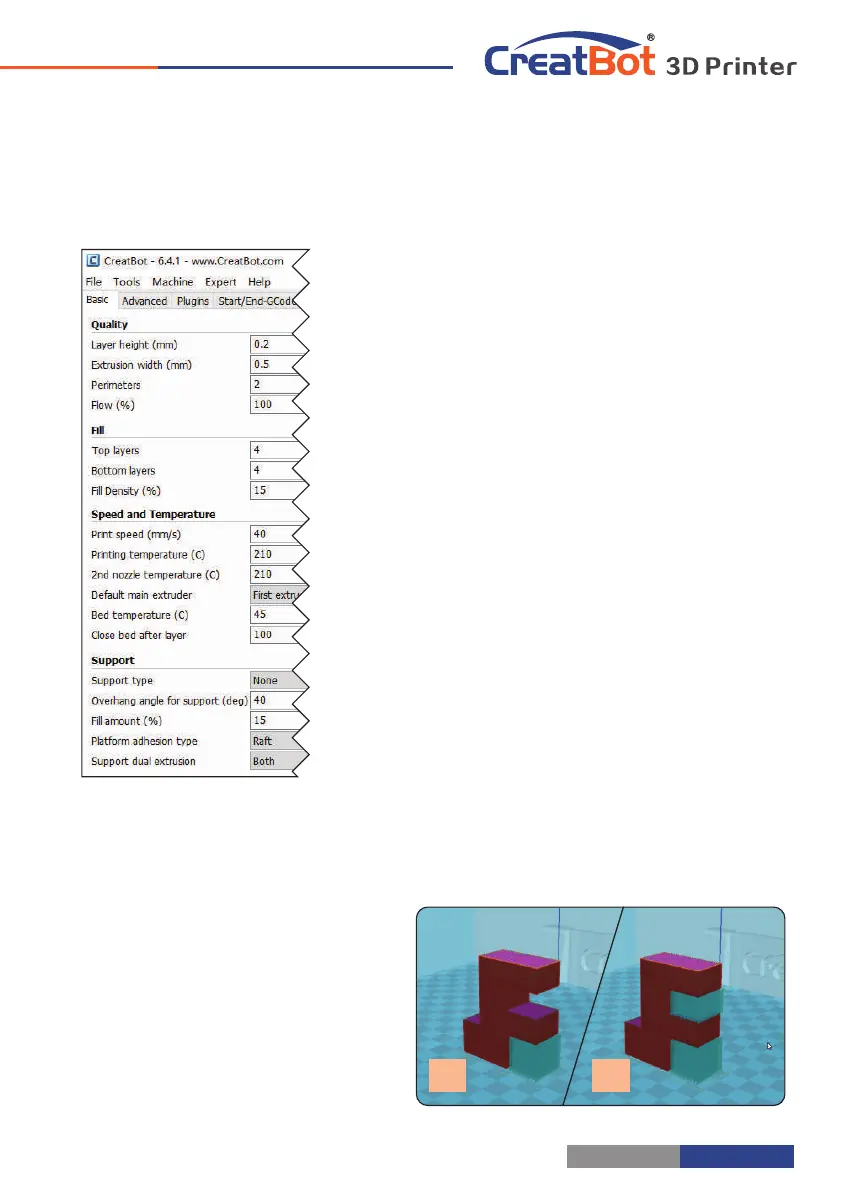

Basic Setting

Software Operation

Layer height: This is the most important setting to determent the

quality of your print, maximum value not exceed 80% of the

nozzle diameter.

Shell thickness: Refers to the total thickness of the inner and

outer walls, the outer wall is only one, the inner wall can be

more, set this value to an integer multiple of the diameter of

the nozzle.

Flow: Refer to the amount of printing material, 100% standard

dosage, the more material the model prints more plump.

top/bottom thickness: Is the thickness of the upper and lower

models, usually a multiple of layer height.

Fill density: Control how density filled the insides of your print will

be, a value around 20% is usually enough, 0% for hollow.

Print speed: Speed at which printing happens. Print speed is

affected by many factors, it is recommended to use low

speed for complex model, high speed will cause the feed

shortage, need improve nozzle temperature to compensate.

Nozzle temperature: Is the melting temperature of filament,

general use 200 ℃ for PLA and 240 ℃ for ABS.

Bed Temperature: General use 45 ℃ for PLA and 70 ℃ for ABS.

Default main head: The default is the first nozzle, can also be set

to other nozzles, this can reduce the times of changing

filament.

Support type: The touching build plate support type is shown in

figure , everywhere support is shown in figure [A] [B].

Support angle: The larger the angle, the more support generate.

Fill amount: The larger the fill, the more support generate.

Platform adhesion type: The model which is not easy adhesion

on the platform please use Brim, which easy to warped or ABS filament please use Raft.

Support Type

A B

- 27 -

Loading...

Loading...