14

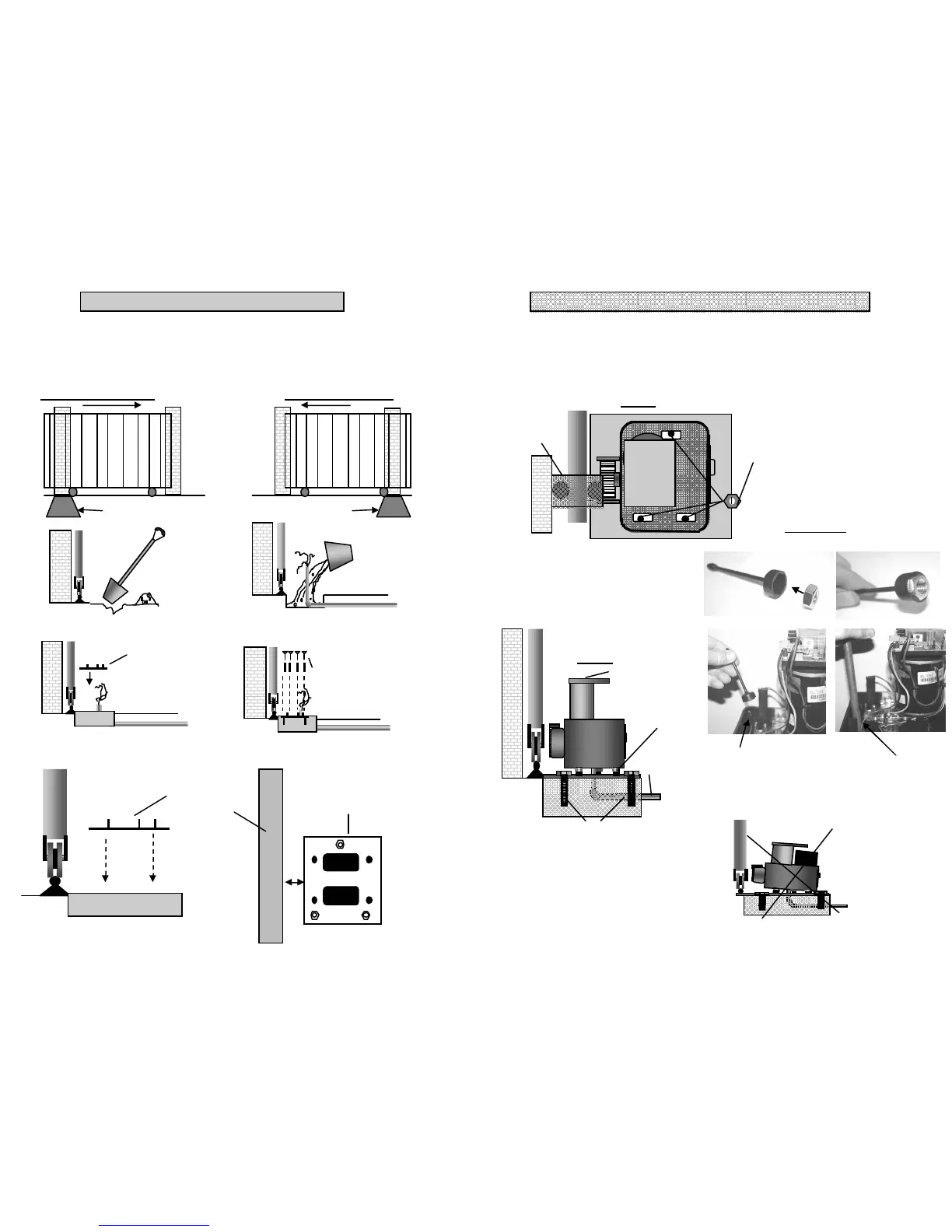

It is very important that the motor is mounted on a firm foundation that can not move or become loose over time. The

foundation should be constructed from concrete. The size of the plinth should be about 300 x 300 mm square and about

200mm deep. The foundation plate supplied with the motor must be securely mounted to the concrete using coach

screws and plugs. The foundation plate can also be welded to the gate rail if need be. The concrete should be allowed

sufficient time to set before the motor is mounted onto the plate.

Allow concrete to set and then place the

foundation plate onto the concrete plinth

3

Foundation plate

Place concrete plinth here

Place concrete plinth here

For a gate closing to the right For a gate closing to the left

2

Place the conduit in the correct position before filling the

hole with concrete. Flexible conduit may also be used.

4

Trim the conduit and the cable to the correct length

before placing the motor onto the foundation plate.

Use 8 mm coach screws to

mount the foundation plate to

the concrete

Dig a hole about 300mm square

1

Top view

Foundation plate

Gate

Side view

Foundation plate

35mm

ANCHORING THE MOTOR

15

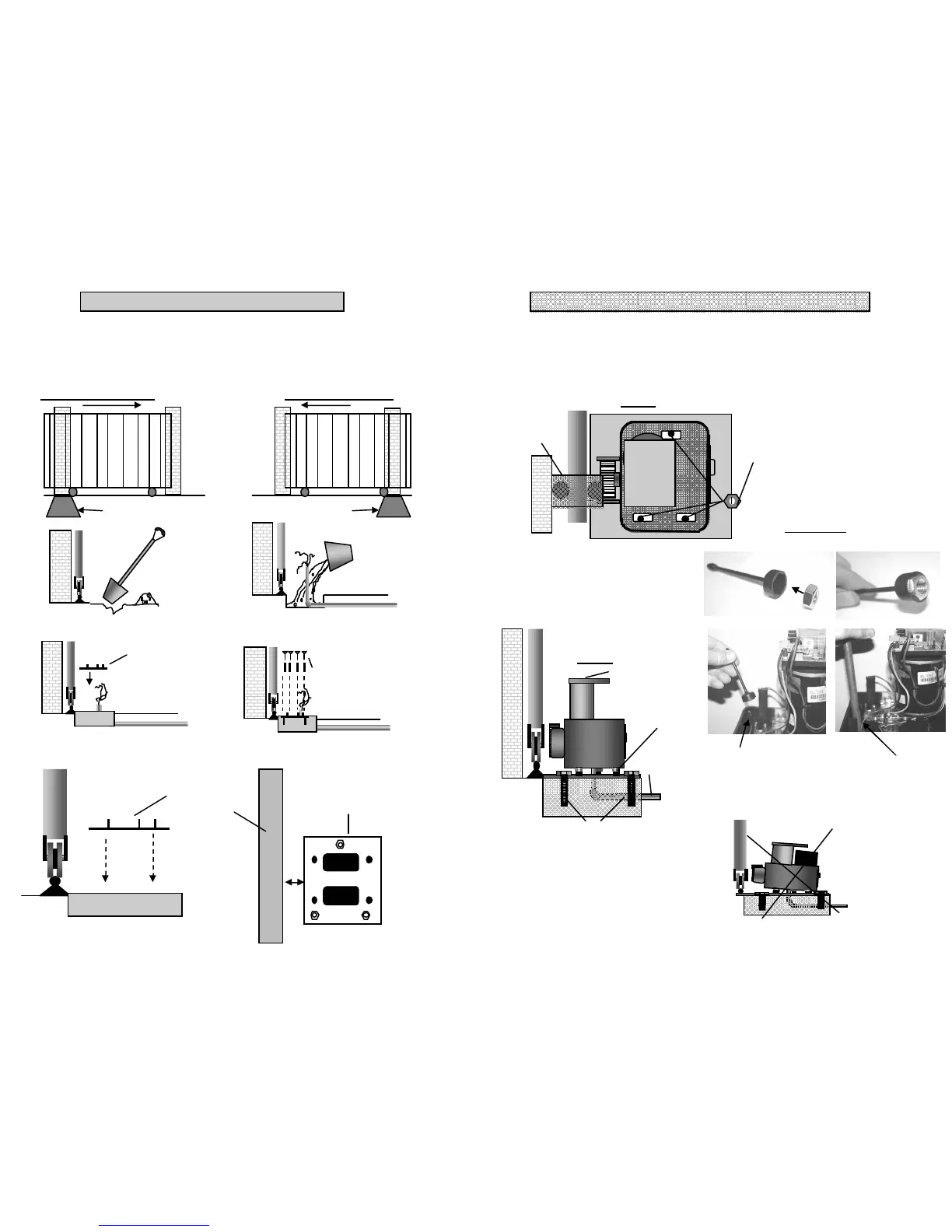

When anchoring the motor it is important to ensure that the following points are checked.

1. The electrical cable is in place.

2. The concrete is fully set.

3. The motor foundation mountings are secure and can not m ove or become loose.

4. The motor should be set level and parallel to the gate.

5. The motor must be set above the flood level or if this is not possible, a flood proof wall should be constructed

around the m otor.

After placing the motor onto the three jack-up

bolts, place the three clamping nuts and washers

over the bolts to clamp the motor in place. Use the

Nut Applicator as shown below.

Top view

Anti-lift device and

Rollers

P.C.B.

Conduit

Jack-up nuts

for adj usting the

motor height.

Concrete plinth

8mm coach screws in plugs

P.C. Board

Side view

Ensure that the m otor is mounted level

SECURING THE MOTOR TO THE FOUNDATION PLATE

Nut Applicator.

Insert the nut into the applicator

Place the nut on the bolt

Tighten the nut with a spanner.

Loading...

Loading...