ENGLISH

11

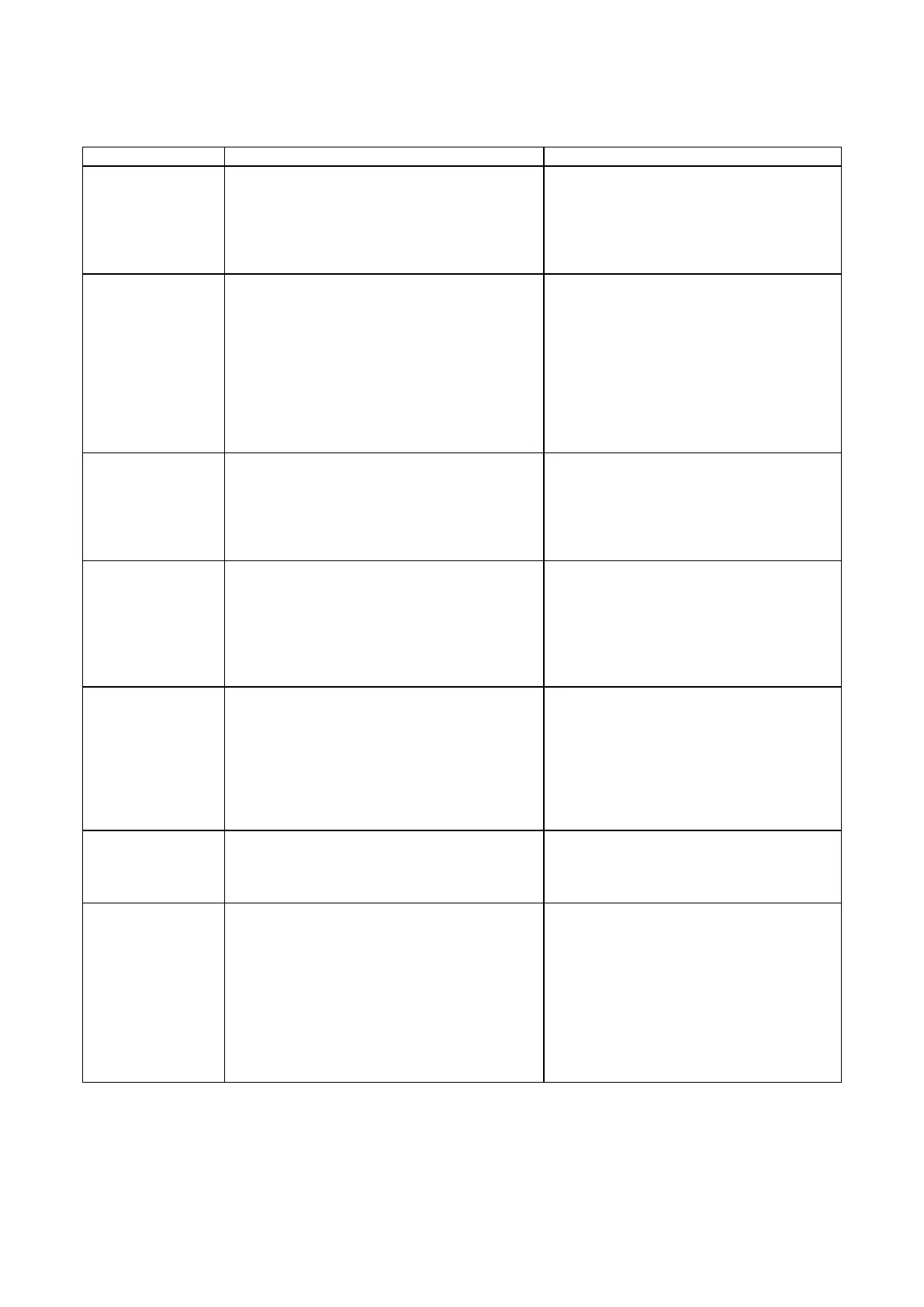

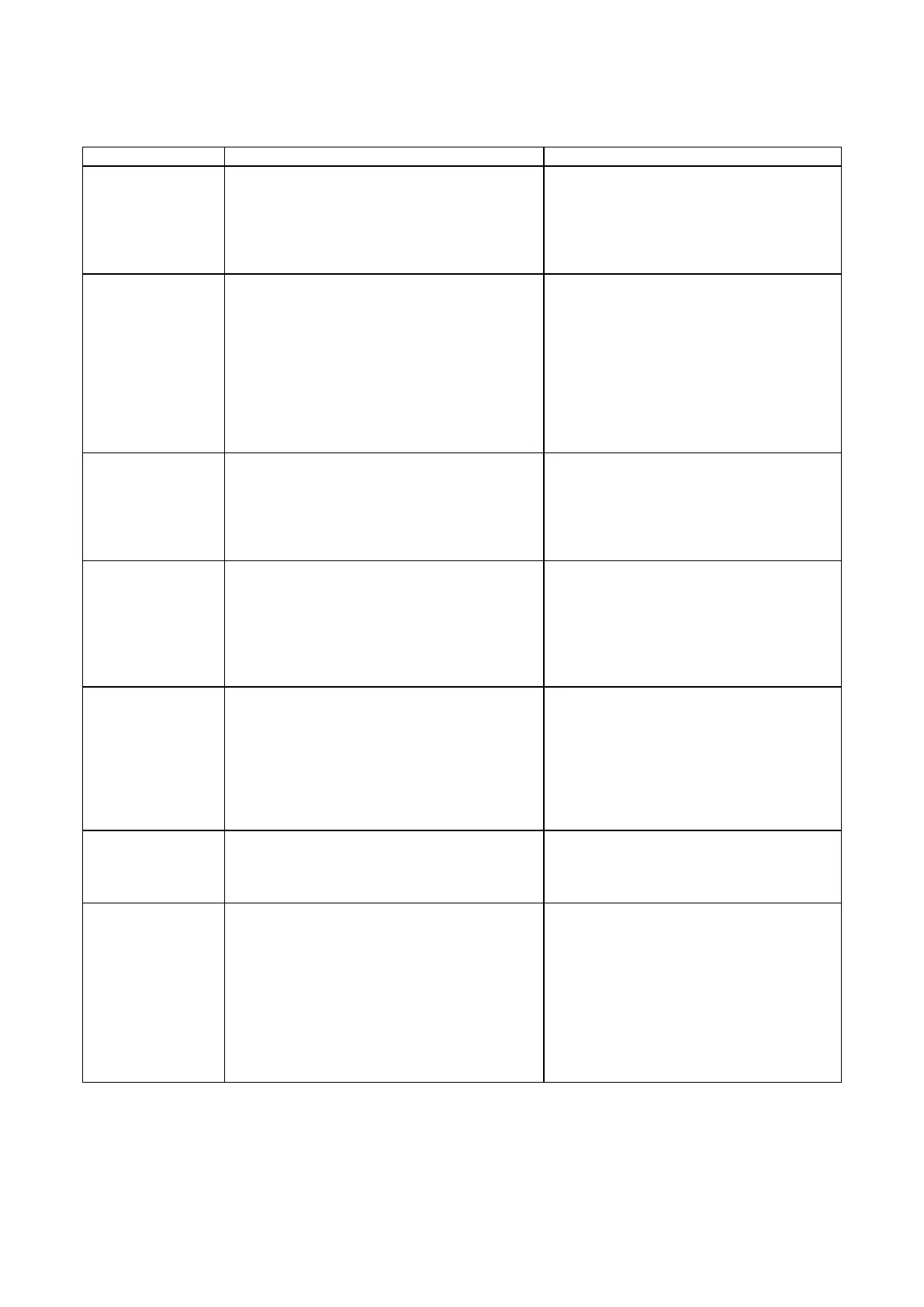

12. TROUBLESHOOTING

not start

A. Check that the motor is powered and that the

voltage corresponds to the value on the data plate

B. Check the presence of all phases for three-phase

motors

C. Dry running

B. Restore the missing one

C.

Lower the pump level or wait for the natural

restoration of the level in the well

2. Motor protection is

activated shortly

after starting

A. Make sure that the supply voltage

corresponds to the value on the data plate

B. Check the presence of all phases

C.

Check the setting of the protection and the

presence of possible open or dirty contacts

D. Check that the liquid temperature is not too high

E. Check f

or excessive torque forces (scraping

between rotating and fixed parts, sand in the

pump, etc.)

B. Restore the missing phase

C.

Restore the protections, consulting the data

plate or replacing the components concerned

E.

Eliminate the cause of friction or clean the

pump to remove any obstructions

3. The motor

protection is

tripped after long

periods of

apparently normal

operation

A. Check that the voltage is sufficient and that all the

phases are present

B. Check for

excessive torque forces (scraping

between rotating and fixed parts, presence of

sand, etc.)

A. Restore the missing phase

B.

Eliminate the cause of friction or clean the

pump to remove any obstructions

4. Motor running but

flow rate is not

sufficient

A. In the three-phase versions check the direction of

rotation

B. Check that the pipes are not partially obstructed

C. Check that the pump flow rate is lower than that of

the well

D. Check the state of wear of the pump

A. Invert any two phase leads

B. Eliminate the obstructions

C.

Replace the pump with one with a lower flow

rate

5. Motor running but

pump does not

deliver

A. Check that there has not been an excessive

lowering of the level of the well re

possible dry running

B. Check that the required head is not

that of the pump

C. In the three-

phase versions check the direction of

rotation

D. Pump blocked by impurities

A. Wait for the natural level to be restored or

lower the level of the well. Install adequate

protection against dry running

B. Replace the

pump with one with suitable

characteristics

C. Invert two phase leads

D. Clean the pump, grid or pipes

insufficient

A. Check for leaks in the system

B. In the three-

phase version check the direction of

rotation

C. Check the state of wear of the pump

A. Take action to eliminate leaks

B. Invert two phase leads

7. Pump starts and

stops too

frequently

A. Check for leaks in the system

B. Check the correct operation of the check valve

C. Check the efficiency of the pressure switch, if used

D. Check that the tank is of sufficient size

E. Check the position of the prob

running, if used

A. Take action to eliminate leaks

B. Repair or replace the valve

C. Repair or replace the pressure switch

D. Replace it with one of adequate capacity

E. Reposition the

probes to have longer running

times

Loading...

Loading...