TIGHTENING OTHER FITTINGS

Ermeto Tube Fittings

Put nut and sleeve over the tube with head or

shoulder end of sleeve next to nut. Push tube into

counterbore of fitting body as far as possible. Turn

nut clockwise until sleeve holds tube and prevents

movement. Tighten the nut 1-1/4 turns more to seat

sleeve and give a locking action. When necessary to

assemble again, put sleeve over tube and tighten nut

until a sudden increase in torque is felt. Then tighten

1/6 to 1/3 turn more to seat the sleeve.

Flex Fittings

Put nut and sleeve over the tubing and push tube in

to counterbore of fitting body as far as possible.

Tighten the nut until it is against the hex part of the

fitting body.

6 of 7

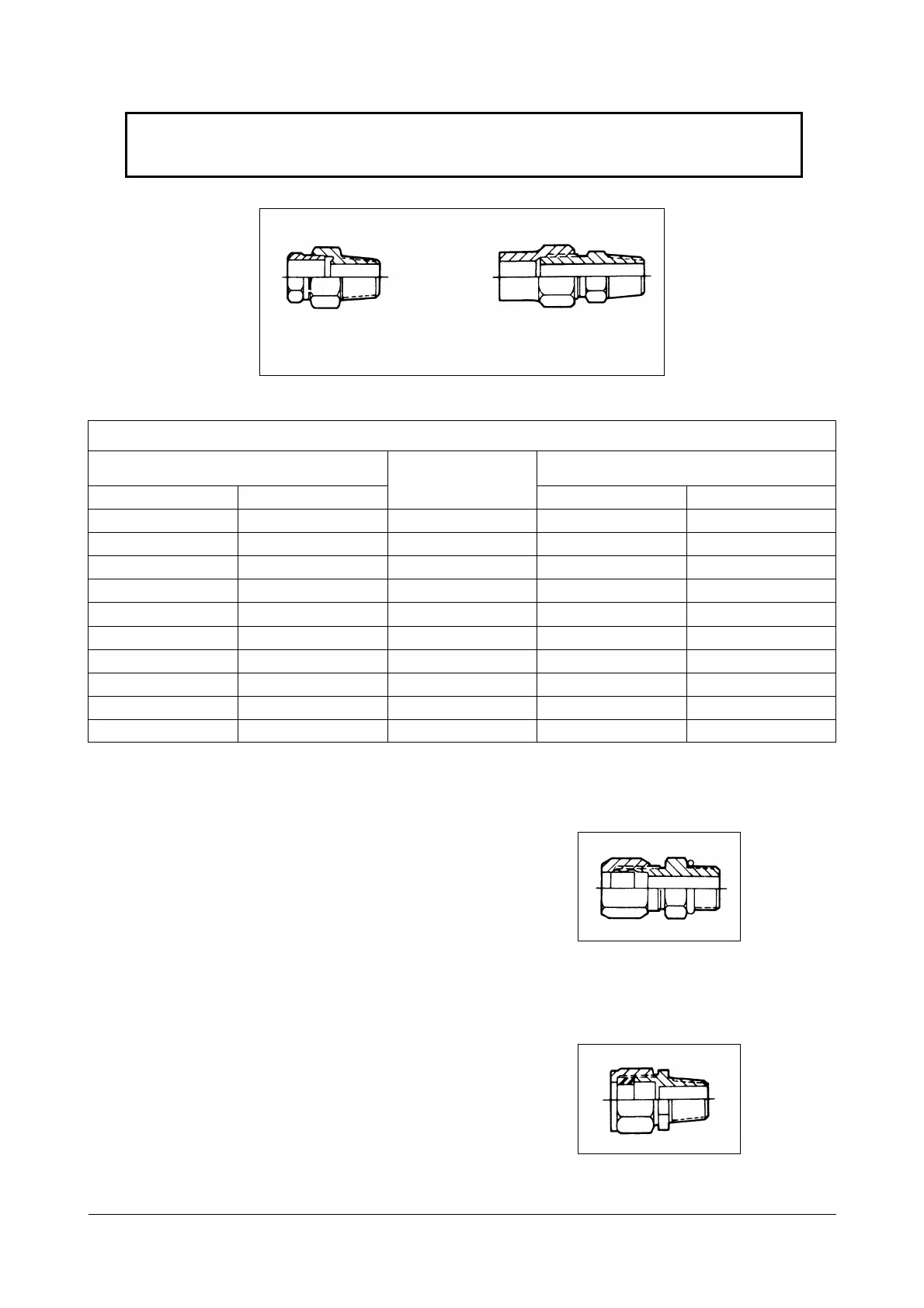

45

û

FLARED AND 45

û

INVERTED FLARE FITTINGS

INVERTED

45

û

FLARED

45

û

FLARED

45

û

FLARED AND 45

û

INVERTED FLARE FITTINGS

NOMINAL TUBE O.D. STANDARD TORQUE

METRIC

3.18

4.76

6.35

7.94

9.52

11.11

12.70

15.88

19.05

22.22

INCH

.125

.188

.250

.312

.375

.438

.500

.625

.750

.875

(N

i

m)

5.0

± 1.5

8.0

± 1.5

11

± 2

17

± 3

30

± 3

30

± 3

38

± 4

50

± 5

90

± 8

100

± 10

(lb

i

ft)

4

± 1

6

± 1

8

± 1

13

± 2

22

± 2

22

± 2

28

± 3

37

± 4

65

± 6

75

± 7

THREAD

SIZE

inch

5/16

3/8

7/16

1/2

5/8

11/16

3/4

7/8

1-1/16

1-1/4

IDAS007B

IDAS008B

IDAS009B

Loading...

Loading...