1 of 7

STANDARD TORQUE FOR METRIC FASTENERS

NOTE : Take care to avoid mixing metric and inch dimensioned fasteners.

Mismatched or incorrect fasteners can result in vehicle damage or malfunction, or

possible injury. Exceptions to these torques are given in the Service Manual where

needed.

NOTE : Prior to installation of any hardware, be sure components are in near new

condition. Bolt and nut threads must not be worn or damaged. Hardware must be

free of rust and corrosion. Clean hardware with a non-corrosive cleaner and apply

engine oil to threads and bearing face. If thread lock or other compounds are to be

applied, do not apply engine oil.

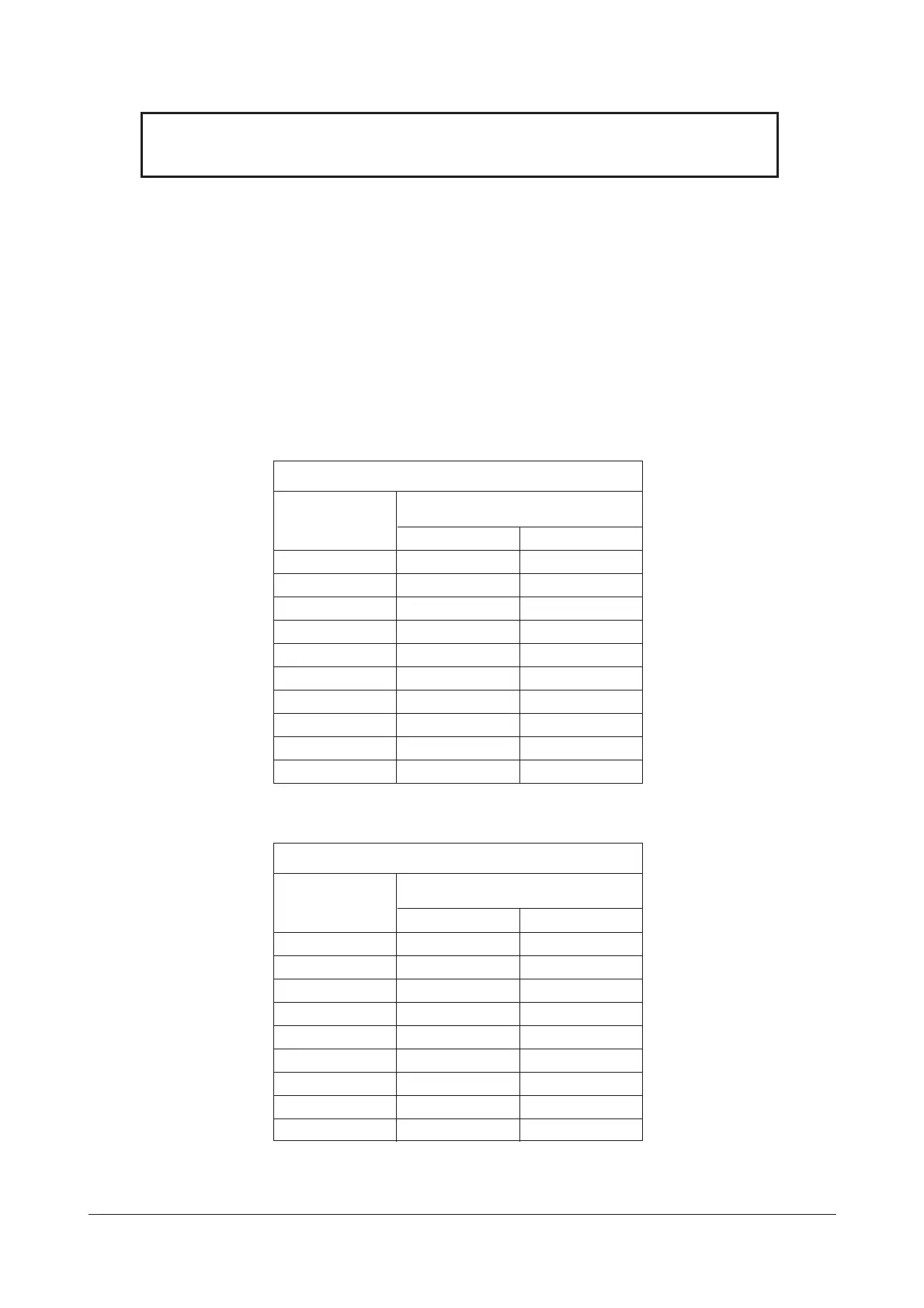

METRIC NUTS AND BOLTS

THREAD

SIZE

(mm)

M6

M8

M10

M12

M14

M16

M20

M24

M30

M36

(N

i

m)

12

± 3

28

± 7

55

± 10

100

± 20

160

± 30

240

± 40

460

± 60

800

± 100

1600

± 200

2700

± 300

(lb

i

ft)

9

± 2

20

± 5

40

± 7

75

± 15

120

± 22

175

± 30

340

± 44

600

± 75

1200

± 150

2000

± 225

STANDARD TORQUE

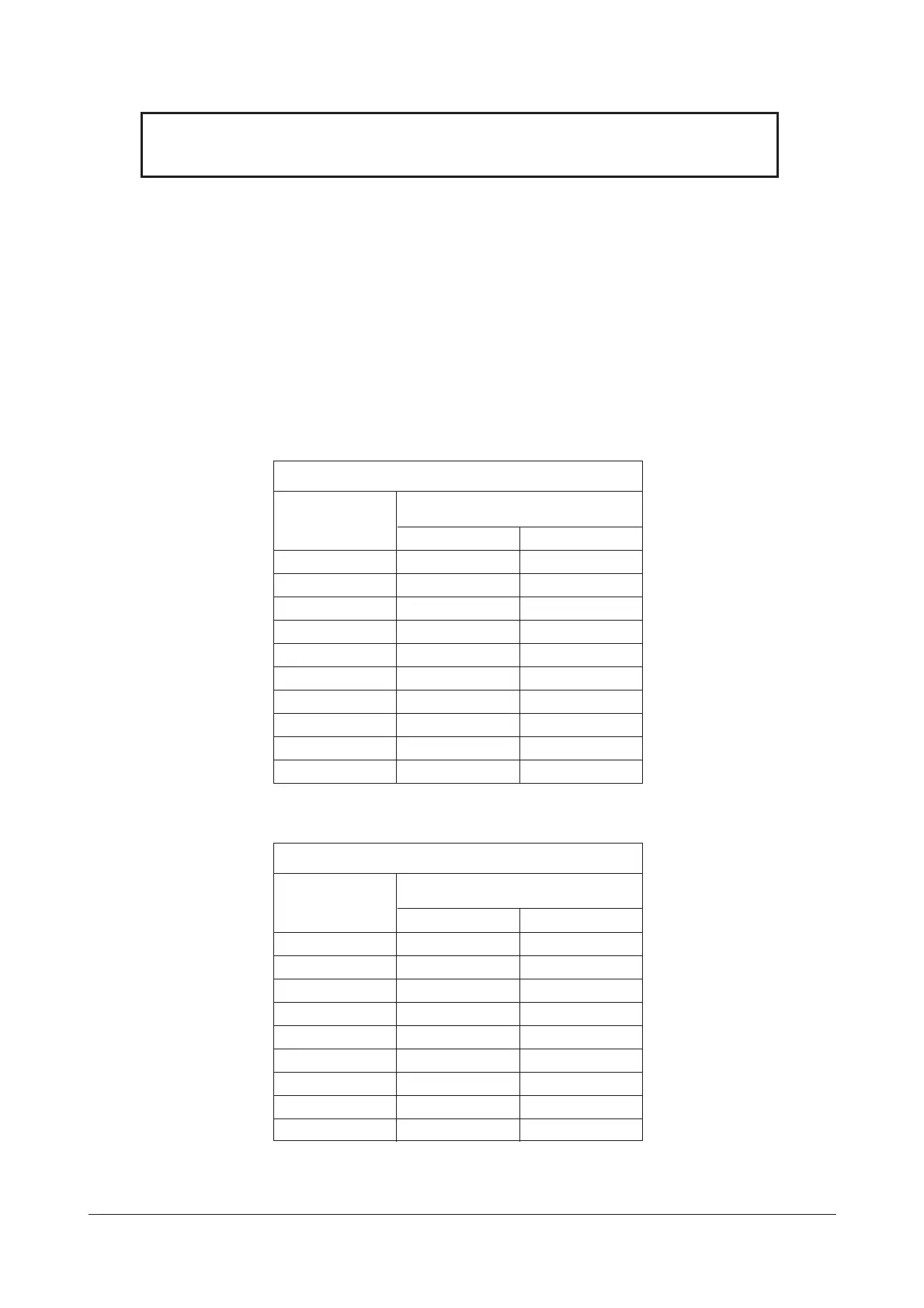

METRIC TAPERLOCK STUDS

THREAD

SIZE

(mm)

M6

M8

M10

M12

M16

M20

M24

M30

M36

(N

i

m)

8

± 3

17

± 5

35

± 5

65

± 10

110

± 20

170

± 30

400

± 60

650

± 80

870

± 100

(lb

i

ft)

6

± 2

13

± 4

26

± 4

48

± 7

80

± 15

125

± 22

300

± 45

480

± 60

640

± 75

STANDARD TORQUE

Loading...

Loading...