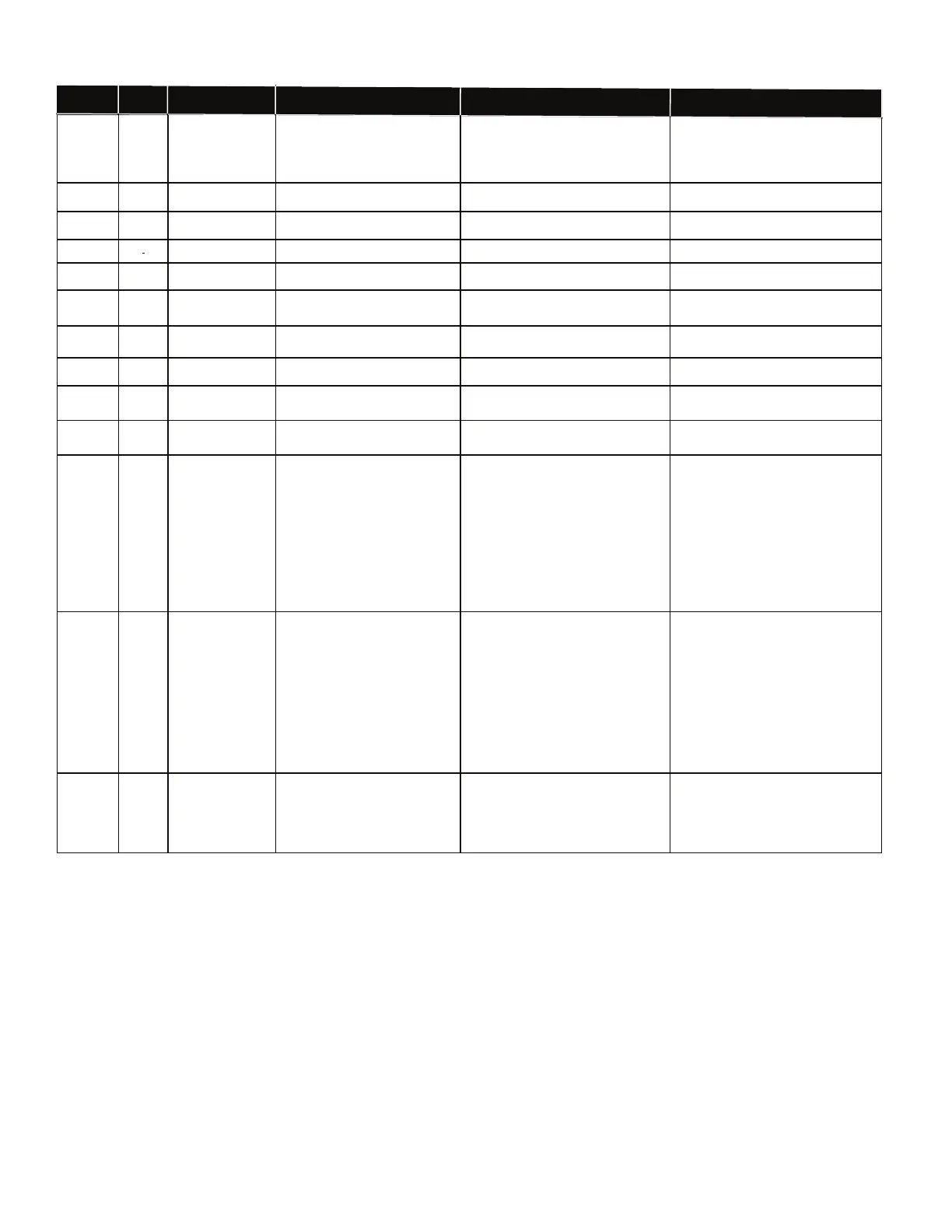

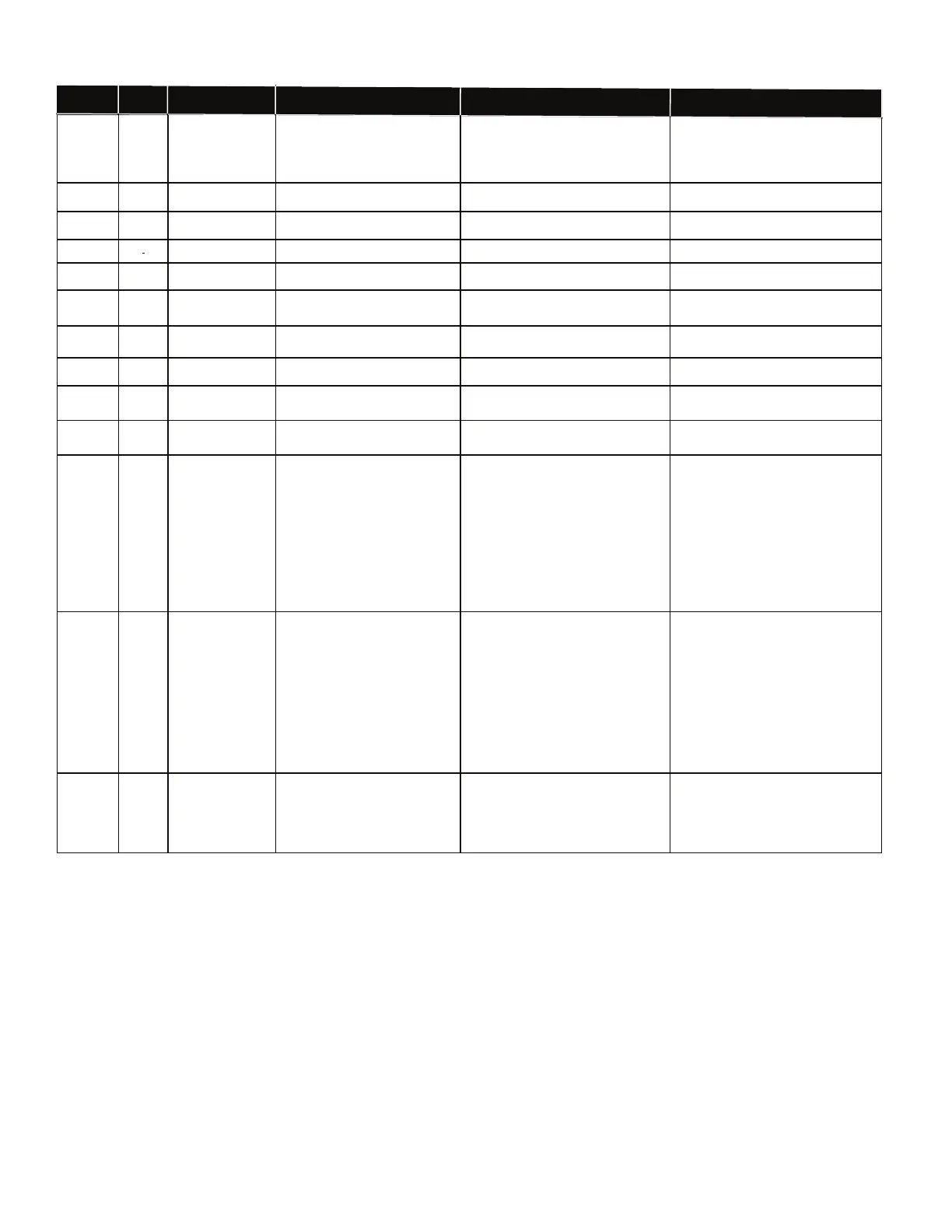

● Discharge thermistor is put on incorrect position or off

● Low refrigerant charge

● Overcharge

● Faulty compressor

● Check discharge thermistor resistance and connections;

Repair/replace as needed

● Check discharge thermistor position

● Check refrigerant charge level; Adjust if needed

● Check the compressor; Repair/replace if needed

23 E23 DISCH TEMP FAIL

The control has detected that the Discharge

Tempera

ture Sensor is out of range.

● Discharge thermistor inoperable or improperly connected

● Faulty outdoor thermistor sensor or disconnect ● Inspect and test sensor; Replace sensor if needed

26 E26 PRESSURE SENSOR

The control determines that the pressure sensor is

not reacting properly.

● Low pressure sensor inoperable or not properly

connected

● Check the connection to low pressure sensor;

Repair/replace if needed

27 E27 COIL TEMP FAIL1

The control detect that the Outdoor Defrost Sensor

is out o

f range.

● Outdoor defrost thermistor inoperable or not properly

connected

● Check the connection to OD defrost thermistor; Repair

as needed

28 E28 COIL TEMP FAIL2

The control has detected that the Outdoor Coil

Temperature Sensor is out of range.

● Outdoor coil thermistor inoperable or not properly

connected

● Check the connection to OD coil thermistor;

Repair/replace if needed

29 E29 LIQ TEMP FAIL

The contro

l has detected that the Liquid

Temperature Sensor is out of range.

● Liquid thermistor inoperable or not properly connected

32 E32 HI TEMP CTRL1

This error indicates the equipment is experiencing

high temperature faults on the outdoor control

board.

● Ambient air conditions too high

● Cooling bracket screw(s) missing or not properly

fastened (2-4 ton only)

● No or poor thermal grease coating between cooling

plumbing and cooling bracket on control board (2-4 ton

only)

● Outdoor fan low speed (5 ton only)

● No flow or limited fl

ow through control board cooling

circuit (potential restriction in line or low refrigerant) (2-4

ton only)

● Stop valve not completely open (2-4 ton only)

● Cycle power; re-try during usable ambient temperature

range

● Verify cooling bracket screws in place and secure;

Secure fasteners as needed (2-4 ton only)

● Check thermal grease inside cooling bracket on control

board; Apply additional grease as n

eeded

● Check outdoor fan motor & wiring; Repair/replace if

needed (5 ton only)

● Check for restriction in line

● Check refrigerant charge level; Adjust if needed (2-4 ton

only)

● Check the opening of stop valve, should be full open;

Repair/replace if needed (2-4 ton only)

33 - HI TEMP CTRL2

This error indicates the equipment is experiencing

high temperature faults on the outdoor control

board. Control ha

s determined continued operation

is acceptable. This indicates they may be a

problem with the equipment.

● Ambient air conditions too high

● Cooling bracket screw(s) missing or not properly

fastened (2-4 ton only)

● No or poor thermal grease coating between cooling

plumbing and cooling bracket on control board (2-4 ton

only)

● Outdoor fan low speed (5 ton only)

● No flow or limited flow through contro

l board cooling

circuit (potential restriction in line or low refrigerant) (2-4

ton only)

● Stop valve not completely open (2-4 ton only)

● Cycle power; re-try during usable ambient temperature

range

● Verify cooling bracket screws in place and secure;

Secure fasteners as needed (2-4 ton only)

● Check thermal grease inside cooling bracket on control

board; Apply additional grease as needed

● Check outd

oor fan motor & wiring; Repair/replace if

needed (5 ton only)

● Check for restriction in line

● Check refrigerant charge level; Adjust if needed (2-4 ton

only)

● Check the opening of stop valve, should be full open;

Repair/replace if needed (2-4 ton only)

34 E34 CURRENT SPIKE

Control Board detected a high current condition.

This indicates the potential for a short circuit.

● Current spike in supply

● Stop valve not c

ompletely open

● The compressor wire is lost phase

● Faulty control board

● Faulty compressor

Loading...

Loading...